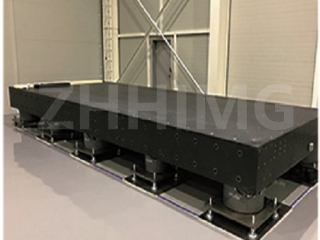

Ukusetshenziswa kwezingxenye ze-granite ku-Coordinate Measuring Machines (CMM) kuwumkhuba osungulwe kahle embonini yokukhiqiza. I-Granite iyidwala elivela ngokwemvelo elinezakhiwo ezinhle kakhulu njengokuzinza kokushisa, i-coefficient ephansi yokwanda kokushisa, kanye nokuqina okuphezulu. Lezi zakhiwo ziyenza ibe yinto efanelekile yokusetshenziswa ekwenziweni kwezinsimbi zokulinganisa ezibucayi njenge-CMMs. Lezi zakhiwo ziqinisekisa ukunemba okuphezulu kokulinganisa okubalulekile embonini yokukhiqiza.

Ukuzinza kokushisa kungenye yezimpawu ezibaluleke kakhulu ze-granite. Ama-CMM ayizinto zokunemba okumele zizinzile ngisho noma kukhona ukushintshashintsha kokushisa. Ukusetshenziswa kwe-granite njengento yokwakha kuqinisekisa ukuthi umshini uhlala uzinzile, kungakhathaliseki ukuthi izinga lokushisa lishintsha. I-coefficient yokwanda kokushisa kwe-granite iphansi, okuqinisekisa ukuthi noma yikuphi ukwanda kokushisa kuncane, okuvumela izilinganiso ukuthi zihlale zihambisana phakathi nobubanzi bokushisa bokusebenza. Lesi sici sibalulekile ekunembeni kwezilinganiso ezenziwe yi-CMM.

I-coefficient ephansi yokwanda kwe-granite ngokushisa iqinisekisa ukuthi izilinganiso ezithathwe yi-CMM zihlala zinembile ngisho noma kunezinguquko zokushisa. Izinguquko zokushisa zingathinta usayizi nesimo sezinto ezilinganiswayo. Kodwa-ke, ukusetshenziswa kwe-granite njengezinto zokwakha ze-CMM kuqinisekisa ukuthi noma yikuphi ukushintsha kwezinga lokushisa akuthinti ukunemba kwezilinganiso. Le mpahla ibalulekile embonini yokukhiqiza, lapho ukunemba kubalulekile ekuqinisekiseni ukuthi imikhiqizo eqediwe ihlangabezana nezidingo zamakhasimende.

Ukuqina okuphezulu kungenye imfanelo ebalulekile eyenza i-granite ibe yinto efanelekile kuma-CMM. Izingxenye ezisetshenziswa kuma-CMM kumele ziqine ukuze zisekele isici sokulinganisa, esivame ukuba yi-probe ebucayi. Ukusetshenziswa kwe-granite kuqinisekisa ukuthi umshini uhlala uqinile, kunciphisa noma yikuphi ukuguquka okubangelwa isisindo sesici sokulinganisa. Le mfanelo iqinisekisa ukuthi i-probe yokulinganisa ihamba ngokunembile ezisekelweni ezintathu (x, y, kanye no-z) ezidingekayo ukuze kuthathwe izilinganiso ngokunembile.

Ukusetshenziswa kwe-granite ekwakhiweni kwe-CMM kuqinisekisa nokuthi umshini uhlala uzinzile isikhathi eside. I-granite iyinto eqinile, eqinile engagobeki, engagobi, noma ehlehle ngokuhamba kwesikhathi. Lezi zakhiwo ziqinisekisa ukuthi umshini uzogcina ukunemba kwawo nokunemba kwawo eminyakeni eminingi yokusebenza. Ngaphezu kwalokho, i-granite imelana nokuguguleka, okusho ukuthi idinga ukulungiswa okuncane, ukunciphisa isikhathi sokungasebenzi kanye nokwandisa isikhathi sokuphila komshini.

Ekuphetheni, ukusetshenziswa kwe-granite ekwakhiweni kwe-CMM kubalulekile ekuqinisekiseni ukunemba okuphezulu kokulinganisa embonini yokukhiqiza. Izakhiwo ezihlukile ze-granite, njengokuzinza kokushisa, i-coefficient ephansi yokwanda kokushisa, kanye nokuqina okuphezulu, kuqinisekisa ukuthi umshini uhlala unembile ngisho noma kukhona ukushintshashintsha kwezinga lokushisa. Ngaphezu kwalokho, ukuqina kwe-granite kanye nokumelana nokuguguleka kuqinisekisa ukuthi umshini ugcina ukunemba kwawo eminyakeni eminingi yokusebenza. Sekukonke, ukusetshenziswa kwe-granite kuma-CMM kuwukutshalwa kwezimali okuhlakaniphile ekuqinisekiseni ukukhiqiza kanye nekhwalithi embonini yokukhiqiza.

Isikhathi sokuthunyelwe: Ephreli-09-2024