Izisekelo ze-granite ziyizingxenye ezibalulekile zemishini ye-CNC (Computer Numerical Control).

Lezi zisekelo zinikeza isisekelo esiqinile sethuluzi lomshini, okubalulekile ekunembeni nasekuqondeni ngesikhathi senqubo yokukhiqiza. Ngakho-ke, usayizi nesimo sesisekelo segranite kumele sivumelane nezidingo ezahlukene zamathuluzi omshini we-CNC.

Abakhiqizi bemishini ye-CNC basebenzisa izinhlobo ezahlukene zezinto zokwakha isisekelo, kodwa i-granite iyona ethandwa kakhulu ngenxa yezakhiwo zayo ezixinene kakhulu kanye nokudlidliza okuphansi. I-granite iyinto efanelekile yezisekelo zomshini njengoba ingagcina isimo sayo ngaphansi kwezimo ezimbi kakhulu, kufaka phakathi amazinga okushisa aphezulu kanye nokucindezeleka okuqhubekayo kwemishini.

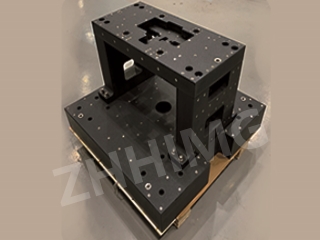

Abakhiqizi bemishini ye-CNC banikeza ububanzi bobukhulu kanye nezimo zesisekelo se-granite, ezingahluka kuye ngobukhulu kanye nesisindo somshini. Emishinini emikhulu ye-CNC, isisekelo singaba nesimo sebhokisi elingunxande noma umklamo ofana no-T. Lo mklamo unikeza ukuzinza okuphezulu kanye nokuqina futhi ubalulekile ezinqubweni zokusika ezinzima.

Ngokuphambene nalokho, imishini emincane ye-CNC izodinga isisekelo se-granite esincane. Ukuma kwesisekelo kungahluka, kuye ngesimo nosayizi womshini. Imishini emincane ingadinga isisekelo esinonxande noma esiyisikwele, okuzohlinzeka ngokuqina okwanele kanye nokuqina kokucubungula izingxenye ezincane kuya kweziphakathi.

Kubalulekile ukuqaphela ukuthi usayizi wesisekelo kanye nesimo kumele kucatshangelwe ngokucophelela lapho kuklanywa umshini we-CNC. Umklamo womshini uzonquma uhlobo lwenqubo yokukhiqiza, usayizi kanye nesisindo sezinto ezicutshungulwayo, kanye nokubekezelelana okudingekayo. Lezi zici zizobe sezinquma usayizi kanye nesimo sesisekelo somshini.

Enye inzuzo yesisekelo se-granite yikhono layo lokunciphisa ukudlidliza okungase kuvele ngesikhathi sokusebenza komshini. I-granite ine-coefficient ephansi yokwanda kokushisa, okusho ukuthi ngeke ikhule noma inciphe kakhulu ngenxa yokushintsha kwezinga lokushisa, okuqinisekisa ukunemba komshini.

Amandla esisekelo se-granite nawo ayisici esibalulekile ekuhlinzekeni ukwesekwa kwezingxenye ezihambayo zomshini. Ngakho-ke, i-granite kumele ibe sezingeni eliphezulu, ingabi nemifantu, futhi imelane nokuguga nokuklebhuka.

Ekuphetheni, ubukhulu nesimo sesisekelo se-granite kumele sivumelane nezidingo ezahlukene zamathuluzi omshini we-CNC. Umklamo womshini uzonquma ubukhulu nesimo sesisekelo esidingekayo kuwo. Ngakho-ke, abakhiqizi kumele bacabangele uhlobo lomsebenzi umshini we-CNC ozowenza, isisindo nosayizi wezinto ezicutshungulwayo, ukunemba nokunemba okudingekayo, kanye nezinga lokudlidliza okukhiqizwayo ngesikhathi senqubo ukuqinisekisa isisekelo esiqinile sethuluzi lomshini. Ekugcineni, isisekelo se-granite esifanele sizosiza ekuhlinzekeni ukusebenza komshini okuthuthukisiwe kanye nokunemba nokunemba okukhulu okungazuzisa izimboni eziningi ezithembele emishinini ye-CNC.

Isikhathi sokuthunyelwe: Mashi-26-2024