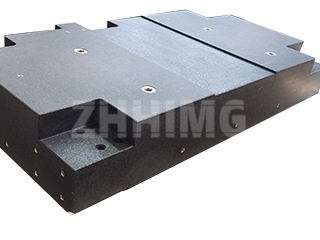

Ingxenye yombhede womshini we-granite imelela ukuphakama kokuzinza kwesakhiwo ekukhiqizeni kwesimanje. Ngokuqina kwazo okungavamile, ukudambisa ukudlidliza okungokwemvelo, kanye ne-coefficient yokukhulisa ukushisa ecishe ibe yi-zero, lezi zingxenye—ikakhulukazi lezo ezenziwe ngezinto ezixinene kakhulu njenge-ZHHIMG® Black Granite yethu—zibalulekile emishinini ye-CNC yesizukulwane esilandelayo, imishini yokulinganisa enembile kakhulu, kanye nezinhlelo ze-laser ezithuthukisiwe. Kodwa-ke, ukusebenza kwalezi zingxenye ezinembe kakhulu kufana nokusetha kwazo kokuqala. Ukunamathela ngokucophelela ezimisweni zangaphambi kokufakwa kubalulekile ukuvula amandla aphelele nokwandisa isikhathi sokusebenza sohlelo lonke.

Uhambo oluya ekuqondeni luqala ngesigaba sokuhlola okuphelele kanye nokulungiselela. Ngaphambi kokufakwa, ingxenye kumele idlule ekuhlolweni okubukhali nokubonakalayo. Onjiniyela kumele bahlole ngokucophelela ubuso be-granite ukuthola noma yikuphi ukuqhekeka okuncane, ukuqhekeka, noma umonakalo wokuphatha okungenzeka ukuthi kwenzeke ngesikhathi sokuthutha. Okubaluleke kakhulu, ubukhulu obuqinisekisiwe bengxenye kanye nokunemba kwe-geometric—ukuba yisicaba, isikwele, kanye nokulingana—kumele kuqinisekiswe kabusha kusetshenziswa amathuluzi athuthukisiwe okumetrology, ukuqinisekisa ukuthi umbhede uhlangabezana nokubekezelelana okuhlosiwe kokucubungula noma ukulinganisa. Ngesikhathi esifanayo, ukuhlolwa kwemvelo kubalulekile. Njengomhlinzeki womhlaba wonke, i-ZHHIMG® idinga abasebenzisi ukuthi baqinisekise ukuthi indawo yokufaka ihambisana nemingcele eqinile yokushisa kanye nomswakama, ivikele ukuzinza kwesikhathi eside kwe-granite ezimweni ezimbi ngaphambi kokuba inqubo yokuhlanganisa iqale.

Ngesikhathi senqubo yokufaka, ukulawula isisekelo kubaluleke kakhulu. Isisekelo esamukelayo kumele sibe siqinile, sibe sezingeni elifanele, futhi sihlukaniswe nokudlidliza okungenzeka nezinkinga zokuxazulula. Noma yikuphi ukungalingani esisekelweni kuzoletha ukucindezeleka kwendawo ku-granite, okuthi, naphezu kwamandla ayo, kuzobeka engcupheni ubuqotho bokugcina bejometri. Amathuluzi okulinganisa ngokunembile kanye nama-shim kumele asetshenziswe ukulawula ngokucophelela ukuhambisana okuvundlile, kuyilapho izinkomba ezibalulekile ezifana nokuma okuqondile kanye nokuhambisana kufanele zilawulwe ezingeni le-sub-micron, okubonisa amazinga aqondile endawo yethu yokukhiqiza. Ngaphezu kwalokho, ukuhlanganiswa nokubopha kombhede we-granite kuso sonke isakhiwo somshini kudinga ulwazi olukhethekile. Ama-fasteners nama-bonding agents alinganiswe kahle kumele asetshenziswe, kusetshenziswa amanani e-torque acacisiwe ukuqinisekisa ukuxhumana okuqinile, okuzinzile ngaphandle kokudala ukucindezeleka okukhulu kwangaphakathi okungalimaza i-granite noma kuphazamise i-geometry yayo eqondile.

Ngaphambi kokuba uhlelo ludluliselwe ekukhiqizweni, isigaba esiphelele sokusebenza kanye nokuhlola siyimpoqo. Lesi sigaba sihilela ukuhlolwa kokusebenza kwazo zonke izingxenye ezihambayo ezihlanganisiwe, njengeziqondiso eziqondile kanye nezinhlelo zokushayela, ukuqinisekisa ukunyakaza okubushelelezi, okungaphazanyiswa ngaphandle kokubopha noma umsindo ongavamile. Lokhu kulandelwa ngokushesha ukuqinisekiswa kokunemba kohlelo lokugcina. Sisebenzisa imishini yokulinganisa elandelekayo—njengaleyo evela kubalingani bethu njengoRenishaw noWYLER—ukunemba okuphelele kwejometri yomshini ohlanganisiwe kumele kuqinisekiswe ngokumelene nemingcele yokusebenza ecacisiwe. Noma yikuphi ukuphambuka kumele kuhlaziywe futhi kulungiswe ngokushesha, kuqinisekiswe ukuthi imishini iyahambisana nezindinganiso ezifana ne-German DIN noma i-US ASME ngaphambi kokuba noma yiziphi izinto zicutshungulwe. Okokugcina, izinhlelo zokuphepha zokusebenza kumele zihlolwe, futhi abasebenzi kumele bathole ukuqeqeshwa okuphelele ngezinqubo zokuphatha ezifanele kanye nokuphepha ezidingekayo zemishini enembile kakhulu.

Isici sokugcina sokuhlela ukusetshenziswa kwangaphambi kokusetshenziswa isu lokunakekela. Nakuba i-granite yaziwa ngokuqina kwayo, ukunakekelwa okufanele kuqinisekisa isikhathi sayo sokuphila isikhathi eside. Isimiso sokuhlanza ngezikhathi ezithile kusetshenziswa izindwangu ezithambile kuphela kanye nezihlanzi ezingathathi hlangothi kumele sisungulwe, okuvimbela ngokusobala amathuluzi okukhuhla angaklwebha indawo eqondile. Okubaluleke kakhulu, inqubo yokugcoba izingxenye zensimbi eziveziwe kanye nokwelapha izingxenye zensimbi eziveziwe ukuze kuvinjelwe ukugqwala kufanele isetshenziswe. Ngokulandela ngokucophelela lezi ziqondiso eziphelele zokufaka kwangaphambi kokusetshenziswa kanye nokusetshenziswa kwangaphambi kokusetshenziswa, abakhiqizi baqinisekisa ukuthi i-ZHHIMG® Granite Machine Bed Component inikeza ukusebenza okuhle kakhulu, impilo yesevisi ende, kanye nokuzinza okungantengantengi eyaklanyelwa ukukunikeza.

Isikhathi sokuthunyelwe: Novemba-17-2025