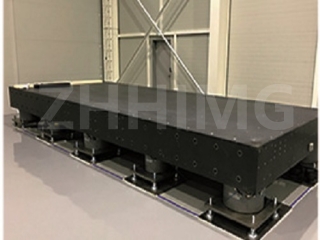

I-Granite iyinto ethandwayo yamapulatifomu e-linear motor ngenxa yokwakheka kwayo okuyingqayizivele. Ukwakheka kwe-granite, okuhlanganisa i-quartz, i-feldspar, ne-mica, kudlala indima ebalulekile ekunqumeni ukufaneleka kwayo kumapulatifomu e-linear motor.

Ukuba khona kwe-quartz ku-granite kuyinika ubulukhuni nokuqina okumangalisayo, okwenza kube yinto efanelekile yamapulatifomu e-linear motor. Ubulukhuni be-quartz buqinisekisa ukuthi ubuso be-granite bungamelana namazinga aphezulu okucindezeleka kanye nengcindezi ekhishwa ama-linear motor. Lesi sici sibalulekile ekuqinisekiseni ukuzinza kanye nobude besikhathi sepulatifomu ye-linear motor.

Ngaphezu kwalokho, okuqukethwe yi-feldspar ku-granite kunegalelo ekhonweni layo lokumelana nokuguguleka. Amapulatifomu e-linear motor ahlala enyakaziswa futhi engqubuzana, futhi ukuba khona kwe-feldspar kusiza i-granite ukuthi igcine ubuqotho bayo besakhiwo ngokuhamba kwesikhathi. Lokhu kubalulekile ukuqinisekisa ukusebenza okubushelelezi nokuthembekile kwamapulatifomu e-linear motor ezisetshenziswayo ezimbonini nasezentengiselwano ezahlukahlukene.

Ngaphezu kwalokho, okuqukethwe yi-mica ku-granite kuyinikeza izakhiwo ezinhle kakhulu zokuvikela ugesi. Lokhu kubaluleke kakhulu kumapulatifomu e-linear motor, njengoba kusiza ukuvimbela ukuphazamiseka kukagesi futhi kuqinisekisa ukusebenza kahle kwama-motor. Amandla e-granite okuvikela ugesi ngempumelelo emifuleni kagesi enza kube ukukhetha okuthandwayo kwamapulatifomu e-linear motor ezinhlelweni zobunjiniyela be-elekthronikhi nobunembile.

Ekuphetheni, ukwakheka kwezinto ze-granite, ikakhulukazi ukuba khona kwe-quartz, i-feldspar, ne-mica, kuthonya kakhulu ukufaneleka kwayo kumapulatifomu e-motor aqondile. Inhlanganisela yobunzima, ukumelana nokuguguleka, kanye nezakhiwo zokufaka ugesi kwenza i-granite ibe yinto efanelekile yokusekela izidingo zokusebenza okuphezulu kwamapulatifomu e-motor aqondile. Amandla ayo okubekezelela ukucindezeleka, ukugcina ubuqotho besakhiwo, kanye nokuhlinzeka ngokufakwa ugesi kwenza i-granite ibe ukukhetha okuthembekile nokuhlala isikhathi eside kwamapulatifomu e-motor aqondile kuzo zonke izimboni.

Isikhathi sokuthunyelwe: Julayi-08-2024