Emkhakheni wokulinganisa ngokunemba, ukuzinza kwesisekelo semishini yokulinganisa kunquma ngqo ukuthembeka kwedatha. Inkinga yephutha lokulinganisa elibangelwa ukuguqulwa kokushisa kwezisekelo zensimbi ephonswe isikhathi eside ihlupha imboni yokukhiqiza. Kodwa-ke, ipulatifomu yethuluzi lokulinganisa i-granite flatness eyasungulwa yi-ZHHIMG, enesitifiketi sayo sokunemba sezinga le-AAA esidlula amazinga embonini, inikeza ikhambi eliguqukayo lokulinganisa ngokunemba okuphezulu.

Inkinga yokuguquguquka kokushisa kwezisekelo zensimbi ephonswe: Umbulali Ongabonakali wamaphutha okulinganisa

Izisekelo zensimbi ephothiwe zazisetshenziswa kabanzi emishinini yokulinganisa ngenxa yezindleko zazo eziphansi kanye nokuqina okuqinile. Kodwa-ke, ekusetshenzisweni okusebenzayo, ukushiyeka kokuzinza kwazo kokushisa okungekuhle kuye kwavela kancane kancane. I-coefficient yokwanda kokushisa kwensimbi ephothiwe iphakeme njengo-11-12 × 10⁻⁶/℃. Lapho imishini isebenza noma izinga lokushisa elizungezile lishintshashintsha, ithambekele kakhulu ekuguqukeni kokushisa. Isibonelo, lapho izinga lokushisa elizungezile eshabhu lishintsha ngo-5℃, isisekelo sensimbi ephothiwe singase siguquke ngomugqa ongu-0.0055-0.006mm. Ushintsho olunjalo oluncane luzobangela ngqo ukuthi ireferensi yokulinganisa ishintshe, kuphindaphinde iphutha lokulinganisa.

Ngaphezu kwalokho, ukuqhutshwa kokushisa kwesisekelo sensimbi ephonswe ngogesi akulingana. Uma imishini isebenza, ukushisa kwendawo kuzobangela "umphumela we-thermal gradient", okuholela ekuphendukeni nasekuguqukeni ebusweni besisekelo. Ekulinganisweni kokuba yisicaba, lokhu kuguquka kungabangela ukuphambuka endaweni ehlobene phakathi kweprobe yokulinganisa nento elinganiswayo, ekugcineni kukhishwe idatha yokulinganisa engalungile. Ngokwezibalo zemboni, zemishini yokulinganisa enezisekelo zensimbi ephonswe ngogesi, amaphutha abangelwa ukuphambuka kokushisa abangela ngaphezu kwama-40% amaphutha aphelele, okuthinta kakhulu ukunemba kokuhlolwa kwekhwalithi yomkhiqizo.

Intuthuko kwezobuchwepheshe yesikhulumi se-granite se-ZHHIMG: Ukuqeda ukuguqulwa kokushisa empandeni

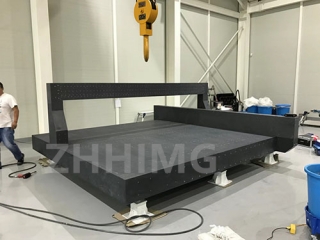

Ipulatifomu yethuluzi lokulinganisa ukuthamba kwe-granite ye-ZHHIMG ithatha i-granite yemvelo njengesisekelo sezinto, ixazulula inkinga yokuguquguquka kokushisa kusukela engqikithini yezinto. I-coefficient yokwanda kokushisa kwe-granite ingu-5-7 × 10⁻⁶/℃ kuphela, okuyisigamu nje sensimbi ephonswe ngensimbi. Ngaphezu kwalokho, isakhiwo sayo sangaphakathi siminyene futhi sifana. Ngisho nangaphansi kokushintsha okukhulu kokushisa, ingagcina usayizi nesimo esizinzile. Imininingwane yelabhorethri ikhombisa ukuthi endaweni enokushintshashintsha kwezinga lokushisa okungu-20℃, ukuguqulwa okuqondile kwepulatifomu ye-granite kungaphansi kuka-0.0014mm, okucishe kube yinto encane.

Ngaphezu kwezinzuzo zezinto ezibonakalayo, i-ZHHIMG isebenzisa ubuchwepheshe bokucubungula obunemba kakhulu obunelungelo lobunikazi. Ngokusebenzisa amasu okugaya nokupholisha e-CNC, ukuthamba kwendawo yesikhulumi kuthuthukiswa kube yi-±0.001mm/m2, kufinyelela ezingeni eliphezulu embonini. Okwamanje, isakhiwo esiyingqayizivele sokukhululwa kokucindezeleka esime njengezinyosi sakhiwe ngaphakathi kwepulatifomu, esithuthukisa ukuqina ngenkathi sihlakaza ngempumelelo ukuguquguquka kwemizuzu okubangelwa ukucindezeleka kokushisa, okuqinisekisa ukuthi ireferensi yokulinganisa ihlala izinzile futhi ithembekile ngaso sonke isikhathi.

Isitifiketi sokunemba kwezinga le-Aaa: Ukuzibophezela kwekhwalithi okusekelwa yigunya

Ipulatifomu ye-granite ye-ZHHIMG idlulile isitifiketi sokunemba sezinga le-AAA yisikhungo esigunyaziwe samazwe ngamazwe. Le nqubo yokuqinisekisa idinga ukuthi iphutha lokulinganisa lemishini lihlale lilawulwa ngaphakathi kuka-±0.3μm ngaphansi kwezinguquko eziningi zemvelo ezifana nokushisa, umswakama kanye nokudlidliza. Ukuze kuhlangatshezwane naleli zinga, i-ZHHIMG isungule uhlelo lokulawula ikhwalithi oluphelele: kusukela ekuhlolweni kwe-ore ye-granite eluhlaza, ukucubungula ngokunemba kuya ekuhlolweni kwemikhiqizo eqediwe, isixhumanisi ngasinye siqashwe ngokuqinile yimishini yokuhlola ezenzakalelayo. Isibonelo, i-interferometer ye-laser isetshenziselwa ukwenza ukuskena kwezinga le-micron ebusweni bepulatifomu ukuqinisekisa ukuthi iphutha lokuthamba liyalungiswa. Ukuqina kokushisa kwepulatifomu kuqinisekiswa ngokulingisa izindawo ezibucayi ngokusebenzisa ilabhorethri yokushisa nomswakama engaguquki.

Ekusetshenzisweni okungokoqobo, ipulatifomu ye-ZHHIMG ibonise izinzuzo ezibalulekile ezimbonini ezifana nama-semiconductor, amalensi optical, kanye nama-mold anembile. Ngemva kokuba ibhizinisi elithile le-semiconductor lethule le pulatifomu, iphutha lokulinganisa ukuthamba lancishiswa ngo-90%, futhi izinga lokukhiqiza umkhiqizo landa ngo-15%, okuxazulula ngempumelelo inkinga yokulungisa kabusha ebangelwa amaphutha okulinganisa.

Ngokuphikisana nokuthuthukiswa kwemboni yokukhiqiza ekuqondeni okuphezulu kanye nobuhlakani, ipulatifomu yethuluzi lokulinganisa i-granite flatness ye-ZHHIMG ichaze kabusha izinga lokulinganisa ngokunemba ngokulawula kwayo okuphelele ekuguqukeni kokushisa kanye nesitifiketi sokunemba kwezinga le-AAA. Ayinikezi nje kuphela iziqinisekiso zokulinganisa ezithembekile zamabhizinisi, kodwa futhi ikhuthaza ukugxuma kobuchwepheshe bemboni kusukela "ekwahluleleni okubonakalayo" kuya "ekutholeni okunembile".

Isikhathi sokuthunyelwe: Meyi-12-2025