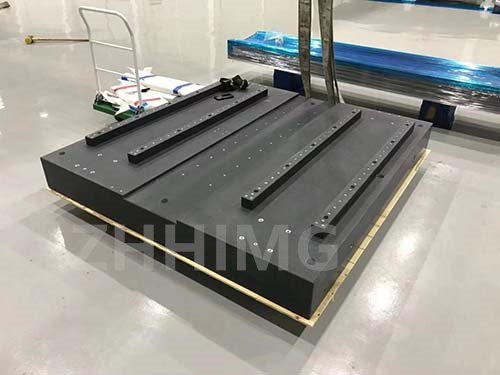

Emkhakheni wokukhiqiza ngokunemba, ukubopha nge-laser kudinga ukunemba okuqondile ukuqinisekisa ubuqotho nokusebenza kwezingxenye eziboshiwe. Izisekelo zomshini we-granite, ikakhulukazi lezo ezivela kubahlinzeki abathembekile njenge-ZHHIMG®, zidlala indima ebalulekile ekufezeni le miphumela enembile. Nansi indlela izakhiwo zazo ezihlukile ezithuthukisa ngayo ukusebenza kwemishini yokubopha nge-laser.

Ukuzinza Okungaqhathaniseki Kokuhambisana Okuqhubekayo

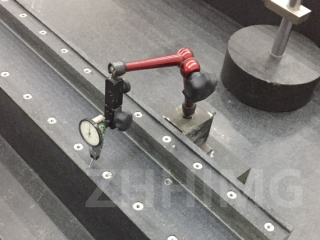

Ukubopha nge-laser kudinga ukuthi izingxenye zihlale ziqondile kahle kuyo yonke inqubo. Izisekelo zomshini we-granite, ezinobukhulu obuphezulu obungaba ngu-3100 kg/m³, zinikeza isisekelo esizinzile kakhulu. Isisindo nokuqina kwe-granite kumelana namandla angaphandle angabangela ukuthi imishini yokubopha ishintshe noma ithambe. Kungakhathaliseki ukuthi ukudlidliza okuvela emishinini eseduze noma ukunyakaza kwabasebenzi phansi efektri, isisekelo esizinzile siqinisekisa ukuthi umthombo we-laser kanye neplatifomu yokubopha zigcina izikhundla zazo eziqondile. Lokhu kuzinza kubalulekile ekufinyeleleni ikhwalithi yokubopha ehambisanayo, njengoba ngisho nokungalungi okuncane kungaholela ekubuthakaneni kwamalunga noma ukwehluleka kokubopha.

Ukudambisa Ukudlidliza Okuphakeme Kwephutha - Ukubopha Okukhululekile

Ama-pulse anamandla aphezulu ama-laser ekusebenzeni kokubopha angadala ukudlidliza kwangaphakathi ngaphakathi kwemishini. Ngaphezu kwalokho, ukudlidliza okuzungezile okuvela endaweni yokukhiqiza kuyisongo esikhulu ekuqondeni. Amandla okudlidliza kwemvelo e-Granite ashintsha kakhulu kulesi simo. Isakhiwo sayo sangaphakathi esiyingqayizivele, esakhiwe yizinhlayiya zamaminerali ezixhumene, simunca futhi sihlakaze amandla okudlidliza ngempumelelo. Ngokunciphisa lokhu kudlidliza, izisekelo zomshini we-granite zivimbela umsebe we-laser ukuthi ungaphambuki ekuqondisweni. Ngenxa yalokho, inqubo yokubopha ingenzeka ngokunemba okukhulu, inciphise ingozi yokusatshalaliswa kokushisa okungalingani futhi iqinisekise amandla e-bond afanayo kulo lonke ijoyinti.

Ukumelana Okushisayo Okumangalisayo Kokulondolozwa Okunembile

Ukushintshashintsha kwezinga lokushisa akunakugwenywa ezindaweni zokukhiqiza, futhi kungaba nomthelela omkhulu ekunembileni kokubopha nge-laser. I-coefficient yokwandisa ukushisa okuphansi ye-Granite iyinzuzo ebalulekile lapha. Ngokungafani nezinsimbi eziningi ezikhula futhi zinciphe kakhulu ngokushintsha kwezinga lokushisa, i-granite igcina ubukhulu bayo ngisho nangaphansi kwezimo zokushisa ezihlukahlukayo. Ekubopheni nge-laser, lapho ukuzinza kokushisa kubalulekile ukugcina izingxenye ze-optical zihambisana futhi kuvimbele ukucindezeleka kokushisa ezintweni eziboshwe, isisekelo somshini we-granite sisebenza njengesivikelo. Siqinisekisa ukuthi indawo egxile kwi-laser ihlala ingaguquki nokuthi indawo yezingxenye ayishintshi ngenxa yokushisa, ngaleyo ndlela ivumela imiphumela yokubopha eqondile nephindaphindayo.

Ukungasebenzi Kwamakhemikhali Kokwethembeka Kwesikhathi Eside

Ukubopha nge-laser kungabandakanya ukusetshenziswa kwamakhemikhali ahlukahlukene ukulungiselela ubuso noma ukuthuthukisa inqubo. Ukungangeni kwamakhemikhali kwe-granite kuyenza imelane nokugqwala okuvela kulezi zinto. Lesi sici sivikela ubuqotho besisekelo somshini ngokuhamba kwesikhathi, siqinisekisa ukuthi siyaqhubeka nokuhlinzeka ngeplatifomu ezinzile nenembile yokusebenza kokubopha nge-laser. Ngokukhetha isisekelo somshini we-granite, abakhiqizi bangagwema izinkinga ezingaba khona ezihlobene nokuwohloka okubangelwa amakhemikhali, njengokugoba noma ubuthakathaka bezinto eziyisisekelo, okungalimaza ukunemba kwenqubo yokubopha.

Ekuphetheni, izisekelo zomshini we-granite zibalulekile ekufinyeleleni imiphumela eqondile yokubopha nge-laser. Ukuqina kwazo, ukudlidliza - ukudambisa, ukumelana nokushisa, kanye nokungangeni kwamakhemikhali kusebenza ngokuvumelana ukudala indawo efanele yokubopha ngokunemba okuphezulu. Uma ufuna ukuthuthukisa ikhwalithi nokuthembeka kwemisebenzi yokubopha nge-laser, ukutshala imali esisekweni somshini we-granite osezingeni eliphezulu, njengalezo ezinikezwa yi-ZHHIMG®, kuyisinqumo esihlakaniphile esikhokhela izinzuzo ngendlela yemiphumela yokubopha ehambisanayo, enembile, nengenamaphutha.

Isikhathi sokuthunyelwe: Juni-03-2025