Emkhakheni oqondile kakhulu wokukhiqiza ama-semiconductor, ngisho nokudlidliza okuncane kakhulu kungathinta kakhulu ukusebenza kwemishini yokubeka ama-wafer, okuholela emaphutheni nasekulahlekelweni kwesivuno. Izisekelo zomshini we-granite zivele njengesixazululo esishintsha umdlalo, sinikeza amakhono okunciphisa ukudlidliza angenakuqhathaniswa abalulekile ekugcineni ubuqotho bokucubungula ama-wafer.

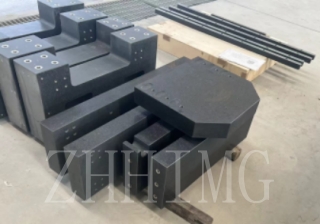

Ubuningi Obuphezulu kanye Nokungakwazi Ukucindezela Ukudlidliza

Ubuningi obukhulu be-granite, obuvame ukuba phakathi kuka-2,600 no-3,100 kg/m³, bunikeza ukungabi namandla okukhulu. Uma buhlanganiswe nemishini yokusika i-wafer, lesi sici simelana nokudlidliza kwangaphandle ngempumelelo. Isibonelo, endaweni ematasa yefektri ye-semiconductor, imishini ezungezile kanye nokuhamba ngezinyawo kungadala ukudlidliza okuzungezile. Isisekelo somshini we-granite, esinobunzima baso obunzima, sisebenza njengesisekelo esizinzile, sinciphisa ukudluliselwa kwalokhu kudlidliza ezingxenyeni ezibucayi zomshini wokusika. Ngenxa yalokho, amathuluzi okusika ahlala ebekwe kahle, kunciphisa ingozi yokusikwa okungeyona inhloso futhi kuthuthukise ikhwalithi iyonke yama-wafer afakwe i-slot.

Ukudlidliza Kwemvelo - Izakhiwo Zokumanzisa

Isakhiwo sangaphakathi esiyingqayizivele se-granite, esakhiwe yizinhlayiya zamaminerali ezixhumene, siyinika amandla amahle kakhulu okudlidliza - ukudambisa. Lapho umshini wokusika i-wafer usebenza, ukujikeleza okusheshayo kwamathuluzi okusika kanye namandla omshini ahilelekile kungadala ukudlidliza kwangaphakathi. I-granite imunca futhi ichithe la mandla okudlidliza, ivimbele ukuthi ingazwakali ngesakhiwo somshini. Ngokungafani nezisekelo zensimbi ezingase zikhulise ukudlidliza, umphumela wemvelo wokudambisa we-granite uqinisekisa ukuthi umshini usebenza kahle. Ucwaningo lubonisa ukuthi ukusebenzisa izisekelo ze-granite kunganciphisa ama-amplitude okudlidliza ngamaphesenti angama-70, okwenza umshini wokusika ugcine izinga eliphakeme lokunemba ngesikhathi senqubo yokusika.

Ukuzinza Kokushisa Ukuze Kuvinjelwe Ukudlidliza - Amaphutha Abangelwayo

Ukushintshashintsha kwezinga lokushisa endaweni yokukhiqiza kungabangela ukuba izinto zande noma zinciphe, okuholela ekungahambelani kahle nasekudlidlizeni okulandelayo. I-Granite ine-coefficient ephansi yokwanda kokushisa, okusho ukuthi igcina isimo sayo nobukhulu bayo ngisho nangaphansi kwamazinga okushisa ahlukahlukene. Emshinini wokufaka i-wafer, lokhu kuzinza kokushisa kubalulekile. Isibonelo, ngesikhathi sokukhiqiza isikhathi eside, umshini ungashisa ngenxa yokusebenza okuqhubekayo. Isisekelo se-granite siqinisekisa ukuthi izingxenye zomshini zihlala zihambisana kahle, zigwema noma yikuphi ukudlidliza okubangelwa ukushisa noma izinguquko zobukhulu ezingathinta ukunemba kokufaka i-wafer. Lokhu kuzinza kusiza ukuqinisekisa ikhwalithi ehambisanayo kuwo wonke ama-wafer acutshunguliwe.

Isisekelo Esiqinile Nesizinzile Sokunemba

Ukuqina kwe-granite kungenye into ebalulekile ekunciphiseni ukudlidliza. Isakhiwo sayo esiqinile sinikeza isisekelo esiqinile somshini wokufaka i-wafer, okuvimbela noma yikuphi ukunyakaza okungafuneki noma ukugoba. Ubuso obunembile bomhlaba wesisekelo somshini we-granite buvumela ukufakwa okunembile kwezingxenye zomshini, okuthuthukisa ukuzinza. Uma umshini ufakwe ngokuqinile esisekelweni se-granite, ungasebenza ngesivinini esiphezulu ngokudlidliza okuncane, okwenza kube lula izikhathi zokucubungula ngokushesha ngaphandle kokulahlekelwa ukunemba.

Izindaba Zempumelelo Zomhlaba Zangempela

Esikhungweni sokukhiqiza esihamba phambili se-semiconductor, ukwamukelwa kwezisekelo zomshini we-granite emishinini yokusika i-wafer kwaholela ekuthuthukisweni okuphawulekayo kwekhwalithi yokukhiqiza. Izakhiwo zokunciphisa ukudlidliza kwe-granite zinciphise ukwenzeka kokuqhekeka okuncane kuma-wafer anezikhala, kwandise izinga lokukhiqiza kusuka ku-85% kuya ku-93%. Ngaphezu kwalokho, ukuzinza okuthuthukisiwe kwavumela ukwanda okungu-20% kwisivinini sokusebenza komshini, kwakhulisa umkhiqizo jikelele.

Ekuphetheni, izisekelo zomshini we-granite zidlala indima ebalulekile ekunciphiseni ukudlidliza emishinini yokubeka i-wafer. Izakhiwo zazo zokuxinana okuphezulu, ukudlidliza - ukudambisa, ukuzinza kokushisa, kanye nokuqina kuhlangana ukudala indawo yokusebenza ezinzile neqondile. Kubakhiqizi be-semiconductor abahlose ukuthuthukisa ikhwalithi kanye nokusebenza kahle kokucubungula kwabo i-wafer, ukutshala imali ezisekweni zomshini we-granite kuyisisombululo esiqinisekisiwe nesisebenzayo.

Isikhathi sokuthunyelwe: Juni-12-2025