IEmbonini yokukhiqiza ye-semiconductor, ukunemba kwemishini yokuhlola i-wafer kubalulekile ekuqinisekiseni ikhwalithi yamasekethe ahlanganisiwe. Izisekelo zomshini we-granite onembile kakhulu, njengalezo ezinikezwa yi-ZHHIMG®, zidlala indima ebalulekile ekuthuthukiseni ukusebenza kwemishini enjalo. Nansi indlela ezenza ngayo umehluko.

I-Exceptional Dimensional StabilityGranite ine-coefficient yokukhulisa ukushisa ephansi kakhulu, cishe (4–8)×10⁻⁶/℃, ephansi kakhulu kunezinsimbi eziningi. Endaweni elawulwa ngokuqinile yezimboni ze-semiconductor, lapho ngisho nokushintshashintsha okuncane kwezinga lokushisa kungabangela amaphutha okulinganisa, izisekelo zomshini we-granite zihlala zizinzile. Lokhu kuzinza kuqinisekisa ukuthi indawo yezingxenye emishinini yokuhlola i-wafer ihlala inembile, ivimbela noma yikuphi ukuphambuka okubangelwa ukushisa okungathinta ukunemba kwemiphumela yokuhlola.

Ukudambisa Ukudlidliza OkuphakemeIphansi lokukhiqiza livame ukugcwala ukudlidliza okuvela emithonjeni eyahlukahlukene. Izakhiwo zokudambisa ezingokwemvelo ze-granite, ezinesilinganiso sokudambisa esingu-0.05–0.1, zimunca futhi zisuse ngempumelelo lokhu kudlidliza. Ukuze uthole i-wafer insp

Ngenxa yokwenziwa kwesenzo, okudinga izithombe ezinesinqumo esiphezulu kanye nokufundwa kwezinzwa okunembile, ukunciphisa ukudlidliza okunikezwa yizisekelo ze-granite kubaluleke kakhulu. Kunciphisa ukuphazamiseka okungafiphaza izithombe noma kuphazamise idatha yezinzwa, okuvumela imishini ukuthi ibambe ulwazi olucacile nolunembile mayelana nobuso be-wafer kanye nesakhiwo sangaphakathi.

Ukuqina Okuphezulu Nokumelana Nokugqokwa Njengoba zinobukhulu obungaba ngu-3100 kg/m³, izisekelo zomshini we-granite ze-ZHHIMG® zinikeza ukuqina okumangalisayo. Zingasekela izingxenye ezisindayo zemishini yokuhlola i-wafer ngaphandle kokuguquka, zigcina ukuhambisana kwezinhlelo zokukhanya nezemishini. Ngaphezu kwalokho, ubunzima obukhulu be-granite (isikali se-Mohs 6–7) kanye nokumelana okuhle kokugqokwa kuqinisekisa ukuthi ubuso besisekelo somshini buhlala buthe tyaba futhi bubushelelezi ngokuhamba kwesikhathi. Lokhu kuvumelana kubalulekile ukuze kube nokunemba kwesikhathi eside, njengoba noma yikuphi ukugqokwa noma ukuguqulwa kwesisekelo kungonakalisa kancane kancane ukunemba kwemishini.

Ukungangeni Kwamakhemikhali Ukukhiqizwa kwe-semiconductor kuhilela ukuchayeka kumakhemikhali ahlukahlukene. Ukungangeni kwamakhemikhali kwe-granite kuyenza imelane nokugqwala okuvela kulezi zinto. Lesi sici sivikela ubuqotho besisekelo somshini, sivimbele umonakalo obangelwa amakhemikhali ongathinta ukuzinza nokunemba kwemishini yokuhlola.

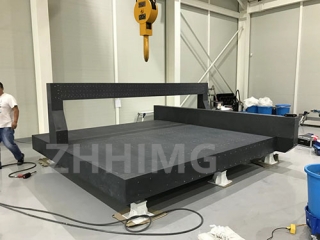

Ekuphetheni, izisekelo zomshini we-granite onembile kakhulu aziyona nje ingxenye kodwa ziyisihluthulelo sokufeza izidingo zokunemba eziqondile zemishini yokuhlola i-wafer. Lapho ukhetha izisekelo zomshini we-granite, khetha abahlinzeki abathembekile njenge-ZHHIMG®. Ngezitifiketi eziningi kanye nokuzibophezela kwikhwalithi, i-ZHHIMG® iqinisekisa ukuthi yonke isisekelo somshini we-granite inikeza ukuthembeka nokusebenza okudingekayo ekukhiqizweni kwe-semiconductor okuthuthukisiwe.

Isikhathi sokuthunyelwe: Juni-03-2025