Ekukhiqizeni okunembe kakhulu kanye ne-metrology, i-granite slab iyisisekelo esingaphikiswana ngaso—inkomba ye-zero-point yokulinganisa ubukhulu. Amandla ayo okugcina indiza ecishe ibe ephelele akuyona nje isici semvelo, kodwa umphumela wenqubo yokubumba elawulwa ngokucophelela, elandelwa ukulungiswa okuhlelekile nokuvamile. Kodwa yiluphi uhambo oluqondile i-granite slab eluthathayo ukuze ifinyelele ukuphelela okunjalo, futhi yiziphi izinqubo ezidingekayo ukuze iqhubeke? Konjiniyela kanye nabaphathi bekhwalithi, ukuqonda kokubili ukuvela kwalokhu kunemba kanye nezinyathelo ezidingekayo zokukulondoloza kubaluleke kakhulu ekugcineni ikhwalithi yokukhiqiza.

Ingxenye 1: Inqubo Yokubumba—Ubungcweti Bokucaba

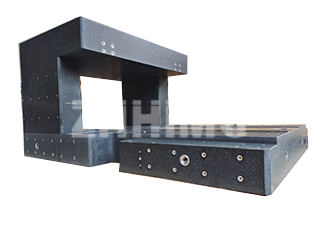

Uhambo lwe-granite slab, kusukela ebhulokini elisikiwe kahle kuya epuletini lobuso elisezingeni lokubhekisela, luhilela uchungechunge lwezigaba zokugaya, ukuzinza, kanye nokuqeda, ngasinye senzelwe ukunciphisa kancane kancane iphutha lobukhulu.

Ekuqaleni, ngemva kokusikwa, i-slab ifakwa ku-Rough Shaping and Grinding. Lesi sigaba sisusa inani elikhulu lezinto zokwakha ukuze kutholakale i-geometry yokugcina kanye nokuba yisicaba okuqinile. Okubaluleke kakhulu, le nqubo iphinde ikhiphe ukucindezeleka okuningi okusele okwakheka etsheni ngesikhathi sokumba kanye nokusika kokuqala. Ngokuvumela i-slab ukuthi "ihlale" futhi izinze kabusha ngemva kwesinyathelo ngasinye esikhulu sokususa izinto, sivimbela ukukhukhuleka kobukhulu besikhathi esizayo, siqinisekisa ukuzinza kwesikhathi eside.

Ukuguqulwa kwangempela kwenzeka ngesikhathi se-The Art of Precision Lapping. Ukuhlanganisa i-lapping kuyinqubo yokugcina, ekhethekile kakhulu ehlunga indawo eyisicaba ibe yindiza yokubhekisela eqinisekisiwe. Lokhu akusikho ukugaya ngomshini; kuwumsebenzi ocophelelayo, onesivinini esiphansi, nocindezela kakhulu. Sisebenzisa amakhemikhali amancane, axegayo aqinile—ngokuvamile i-diamond slurry—afakwe endaweni ewuketshezi, asetshenziswa phakathi kobuso be-granite kanye nepuleti lokuhlanganisa insimbi eqinile. Ukunyakaza kulawulwa ngokucophelela ukuqinisekisa ukususwa kwezinto okufanayo ebusweni. Lo mphumela wokulinganisa, ophindaphindwa ngesandla nangomshini ngezinyathelo eziphindaphindwayo, kancane kancane uhlanza ukuqina kube ngaphakathi kwama-micron noma ngisho nama-sub-micron (ukuhlangabezana nezindinganiso eziqinile njenge-ASME B89.3.7 noma i-ISO 8512). Ukunemba okufinyelelwa lapha akuncane ngomshini kodwa kukhulu ngekhono lomqhubi, esilibheka njengomsebenzi obalulekile, ongenakuphindwa.

Ingxenye 2: Ukugcinwa—Isihluthulelo Sokunemba Okuqhubekayo

Ipuleti lobuso le-granite liyithuluzi lokunemba, hhayi ibhentshi lokusebenzela. Uma seliqinisekisiwe, ikhono lalo lokugcina ukunemba lincike ngokuphelele ezimisweni zomsebenzisi kanye nendawo ezungezile.

Ukulawulwa Kwemvelo kuyisici esisodwa esikhulu esithinta ukunemba kwe-granite. Ngenkathi i-granite ine-coefficient ephansi yokwanda kokushisa (i-COE), umehluko wokushisa phakathi kobuso obuphezulu nobaphansi (i-gradient yokushisa eqondile) ungabangela ukuthi lonke i-slab ligobe noma ligobe kancane. Ngakho-ke, ipuleti kumele ligcinwe kude nokukhanya kwelanga okuqondile, ama-air conditioner drafts, kanye nemithombo yokushisa eyeqile. Indawo ekahle igcina u-68°F ± 1°F ozinzile (20℃ ± 0.5℃).

Ngokuphathelene ne-Use and Cleaning Protocol, ukusetshenziswa okuqhubekayo endaweni ethile kubangela ukuguguleka okungalingani. Ukuze silwe nalokhu, sicebisa ukuthi kujikeleziswe i-slab njalo esitendini sayo futhi kusatshalaliswe umsebenzi wokulinganisa kuyo yonke indawo. Ukuhlanza okuvamile kuyimpoqo. Uthuli kanye nemfucumfucu emincane kusebenza njengezinto ezisusa ukungcola, kusheshiswe ukuguguleka. Kufanele kusetshenziswe izihlanzi ze-granite ezikhethekile kuphela, noma i-isopropyl alcohol ehlanzekile kakhulu. Ungalokothi usebenzise izihlanzi zasekhaya noma izihlanzi ezisekelwe emanzini ezingashiya izinsalela ezinamathelayo noma, uma kumanzi, zipholile okwesikhashana futhi ziphambukise indawo. Uma ipuleti lingasebenzi, kumele limbozwe ngesembozo esihlanzekile, esithambile, esingagugi.

Okokugcina, maqondana noKulungisa Kabusha kanye Nokuvuselela, noma ngabe kunakekelwe kahle, ukuguguleka akunakugwenywa. Kuye ngebanga lokusetshenziswa (isb., Ibanga AA, A, noma B) kanye nomsebenzi, ipuleti lobuso begranite kumele lilungiswe kabusha ngokusemthethweni njalo ezinyangeni eziyi-6 kuya kwezingama-36. Uchwepheshe oqinisekisiwe usebenzisa amathuluzi afana nama-autocollimators noma ama-laser interferometers ukuze ahlele ukuphambuka kobuso. Uma ipuleti liwela ngaphandle kwebanga lalo lokubekezelela, i-ZHHIMG inikeza izinsizakalo zochwepheshe zokuphinda zihlanganiswe. Le nqubo ihilela ukubuyisela i-lap enembile endaweni noma esikhungweni sethu ukuze sibuyisele ngokucophelela i-flat eqinisekisiwe yokuqala, siphinde sisethe kabusha impilo yethuluzi ngempumelelo.

Ngokuqonda inqubo yokubumba ebaluleke kakhulu nokuzibophezela ohlelweni lokulungisa oluqinile, abasebenzisi bangaqinisekisa ukuthi amapuleti abo obuso be-granite ahlala eyisisekelo esithembekile sazo zonke izidingo zabo zekhwalithi yokunemba, amashumi eminyaka alandelanayo.

Isikhathi sokuthunyelwe: Okthoba-24-2025