Izingxenye ze-precision granite zisetshenziswa kabanzi ezimbonini ezahlukahlukene njengemishini, i-elekthronikhi, kanye ne-metrology ngenxa yezakhiwo ezinhle kakhulu zokuzinza, ukuqina, kanye nokunemba okuphezulu. Ukukhanya okumnyama kwezingxenye ze-precision granite kwakheka ngenqubo ethile, enquma ikhwalithi kanye nokubukeka komkhiqizo.

Isinyathelo sokuqala ekudaleni ukukhanya okumnyama kwezingxenye ze-granite enembile ukukhethwa kwamatshe e-granite ekhwalithi ephezulu. Amatshe kufanele acwebezeliswe kahle, angabi namaphutha, futhi abe nokuthungwa okufanayo ukuqinisekisa ukuthi umkhiqizo wokugcina uhlangabezana nokunemba okudingekayo kanye nokuphela kobuso. Ngemva kokukhetha amatshe, afakwa ngomshini ngobukhulu nesimo esidingekayo kusetshenziswa imishini enembile njengemishini ye-CNC kanye nemishini yokugaya.

Isinyathelo esilandelayo ukusebenzisa ukwelashwa okukhethekile kobuso ezingxenyeni ze-granite, okubandakanya izigaba eziningana zokupholisha nokuwaxa. Inhloso yale nqubo ukususa noma yikuphi ukuklwebheka noma imihuzuko ebusweni bengxenye, okwenza ubuso bube bushelelezi futhi bukhanye. Inqubo yokupholisha yenziwa kusetshenziswa izinto ezikhethekile zokuhudula, njenge-diamond paste noma i-silicon carbide, ezinamazinga ahlukene okugoba ukuze kufezwe ukuqeda kobuso okufiswayo.

Uma inqubo yokupholisha isiqediwe, kufakwa ungqimba lwe-wax ebusweni bengxenye ye-granite. I-wax idala ungqimba oluvikelayo oluthuthukisa ukukhanya, okwenza ingxenye ibonakale icwebezela futhi ikhanya. I-wax iphinde isebenze njengengqimba evikelayo, ivimbele umswakama kanye nezinye izinto ezingcolisayo ukuthi zingalimazi ubuso bengxenye.

Okokugcina, ingxenye iyahlolwa ukuze ibone noma yikuphi ukukhubazeka noma ukungapheleli ngaphambi kokuba ivunyelwe ukusetshenziswa. Izingxenye ze-granite eziqondile zivame ukulandelwa izinqubo zokulawula ikhwalithi eqinile ukuqinisekisa ukuthi ziyahlangabezana nezimfuneko ezidingekayo zokunemba kanye nokuqeda ubuso.

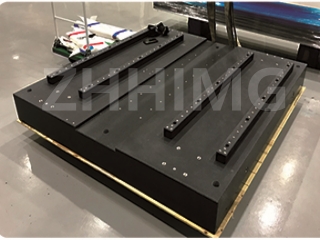

Ekuphetheni, ukukhanya okumnyama kwezingxenye ze-granite enembile kwakheka ngenqubo ecophelelayo ehilela ukukhetha amatshe e-granite asezingeni eliphezulu, ukukhanda ngokunemba, ukupholisha, kanye nokuwaxa. Le nqubo idinga imishini ekhethekile kanye nochwepheshe abanekhono ukuze kufezwe ukuqedwa kobuso obufiselekayo kanye nokunemba. Umphumela uba umkhiqizo ongagcini nje ngokujabulisa ubuhle kodwa futhi onezimpawu zokuzinza nokuqina okwenza kube kuhle ukusetshenziswa ezimbonini ezahlukene.

Isikhathi sokuthunyelwe: Mashi-12-2024