Izidingo ze-metrology yesimanje kanye nokukhiqizwa okukhulu zivame ukudinga ipulatifomu ye-granite enkulu kakhulu kunanoma yiliphi ibhulokhi elilodwa elinganikezwa yi-quarry. Lokhu kuholela kwenye yezinselele eziyinkimbinkimbi kakhulu kubunjiniyela obunembile kakhulu: ukudala ipulatifomu ye-granite ehlanganisiwe noma ehlanganisiwe esebenza ngokuqina kwe-monolithic kanye nokunemba kwezinga le-micron kwengxenye eyodwa.

Kwa-ZHONGHUI Group (ZHHIMG®), ukuxazulula le nselele akukhona nje ukuhlanganisa izingcezu ndawonye; kumayelana nokwenza ijoyinti lingabonakali ngokwe-metrologically.

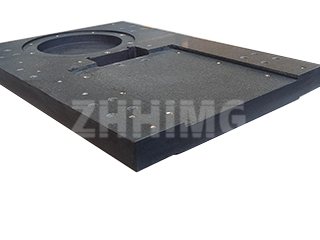

Ngale Kwemingcele Yebhulokhi Elilodwa

Lapho siklama isisekelo seMishini Yokulinganisa Emikhulu (ama-CMM), amathuluzi okuhlola izindiza, noma izinhlelo ze-gantry zesivinini esiphezulu ezenziwe ngokwezifiso, imikhawulo yobukhulu idinga ukuthi sihlanganise izingxenye eziningi ze-granite. Ukuqinisekisa ubuqotho bepulatifomu, ukugxila kwethu kushintshela ezindaweni ezimbili ezibalulekile: Ukulungiswa Komphezulu Okucophelelayo kanye Nokulinganiswa Okuhlanganisiwe kwenhlangano yonke.

Inqubo iqala ngokulungiselela imiphetho yegranite ezohlangana ku-splice. Lezi zindawo azigcini nje ngokuba phansi; zihlanganiswa ngesandla ukuze kufezwe ukuqondeka okumangalisayo kanye nendawo yokuxhumana engenasici. Lokhu kulungiselela okunzima kuqinisekisa ukuxhumana okungokoqobo okucishe kuphelele, okungenazikhala phakathi kwezingxenye, nanoma yikuphi ukuphambuka kobukhulu okulinganiswe ngezingxenyana ze-micron—ukubekezelelana okuqine kakhulu kunobubanzi obudingekayo beplatifomu.

I-Epoxy Yesakhiwo: Isibopho Esingabonakali Sokunemba

Ukukhetha indlela yokuxhuma kubalulekile. Izibambo zendabuko zemishini, njengezibhawodi, zethula ukucindezeleka kwendawo, okuphazamisa kakhulu ukuzinza kwemvelo kwe-granite kanye nezakhiwo zayo zokunciphisa ukudlidliza.

Ukuze kube nokuhlanganiswa okuhlala njalo nokunembile, indinganiso yemboni kanye nendlela yethu esiyithandayo i-Structural Epoxy Bonding esebenza kahle kakhulu. Le resin ekhethekile isebenza njengengqimba yokunamathela encane, eqinile kakhulu enikeza ubuqotho obukhulu besakhiwo. Okubaluleke kakhulu, i-epoxy isabalalisa ukucindezeleka ngokulinganayo kulo lonke ubude nokujula kwesixhumi esihlanganisiwe. Lokhu kuhlanganiswa okungenamthungo kusiza ipulatifomu enkulu ukuthi isebenze njengesisindo esisodwa, esiqhubekayo, esilinganayo, esivimbela ukuphambuka kwendawo okungase kuphazamise idatha yokulinganisa. Umphumela uba isethi ehlala njalo, engashintshi evala ukulungelelaniswa okunembile okutholakala ngesikhathi sokuhlanganiswa.

Ukuhlolwa Kokugcina: Ukuqinisekisa Ukunemba Kuyo Yonke Indawo Ebanzi

Ukunemba kwangempela kwejoyinti ekugcineni kuqinisekiswa ngesikhathi sokulinganisa kokugcina, endaweni. Uma izingcezu seziboshwe ngokuqinile futhi i-assembly isibekwe esitendini sayo sokusekela esenziwe ngokwezifiso, esiqinile kakhulu, yonke indawo iphathwa njengento eyodwa.

Onjiniyela bethu abangochwepheshe basebenzisa amathuluzi okukhanya athuthukile, kufaka phakathi amazinga kagesi kanye nama-interferometer e-laser, ukwenza ukugoqa kokugcina nokulungisa. Balinganisa yonke ipulatifomu, benza ukulungiswa okuncane futhi bagoqa ngokukhetha umugqa ohlangene kuze kube yilapho kufinyelelwa ukuthamba okuphelele okudingekayo kanye nemininingwane yokuphinda ukufunda (ngokuvamile ngokwezindinganiso eziqinile ze-ASME B89.3.7 noma i-DIN 876). Ukuqhubeka kobuso kulo lonke i-splice kuqinisekiswa ngokuqinisekile ngokuhambisa amathuluzi okulinganisa abucayi ngqo phezu kwejoyinti, okuqinisekisa ukuthi akukho sinyathelo noma ukungaqhubeki okubonakalayo.

Kwezinhlelo zokukhiqiza ezithuthukisiwe, ipulatifomu ye-granite engenamthungo nehlanganisiwe ayiyona into efanelekile—kuyisidingo sobunjiniyela esiqinisekisiwe nesithembekile. Sikumema ukuthi uxhumane nathi ukuze sixoxe ngokuthi singaklama kanjani ngokwezifiso futhi sihlanganise isisekelo esihlangabezana nezidingo zakho ze-metrology enkulu ngokunemba okungenakuqhathaniswa.

Isikhathi sokuthunyelwe: Okthoba-17-2025