Uma kukhulunywa ngomshini wokulungisa ngokunemba, ukubaluleka kokukhetha ipuleti lokuhlola i-granite elifanele lomshini wakho we-CNC akunakugcizelelwa ngokweqile. Lawa mapuleti asebenza njengendawo ezinzile neyisicaba yokulinganisa nokuhlola izingxenye ezenziwe ngomshini, ukuqinisekisa ukunemba kanye nekhwalithi ekukhiqizweni. Nazi ezinye izinto ezibalulekile okufanele uzicabangele lapho ukhetha ipuleti lokuhlola i-granite elifanele lomshini wakho we-CNC.

1. Usayizi Nobukhulu: Usayizi wepuleti lokuhlola le-granite kufanele ufane nosayizi wengxenye ehlolwayo. Amapuleti amakhulu anikeza isikhala esiningi sokusebenza, kuyilapho amapuleti amakhulu enikeza ukuzinza okungcono kanye nokumelana nokugoba. Cabanga ngesisindo somshini we-CNC kanye nengxenye elinganiswayo ukuze kutholakale ubukhulu obufanele.

2. Ukuthamba Komphezulu: Ukuthamba kwe-granite slab kubalulekile ekulinganisweni okunembile. Funa i-slab ehlangabezana nezindinganiso zemboni zokuthamba, ngokuvamile ezilinganiswa ngama-micron. Ama-slab okuhlola i-granite asezingeni eliphezulu azoba nokubekezelela ukuthamba okuqinisekisa imiphumela ehambisanayo nethembekile.

3. Ikhwalithi Yezinto Ezisetshenziswayo: Akuyona yonke i-granite edalwe ngokulinganayo. Khetha i-granite enobukhulu obuphezulu engathinteki kalula ekuqhekekeni nasekugugeni. Ikhwalithi ye-granite izothinta ngqo impilo kanye nokusebenza kwebhodi lokuhlola.

4. Ukuphela Komphezulu: Ukuphela komphezulu we-granite slab kuthinta ukunamathela kwamathuluzi okulinganisa kanye nokulula kokuhlanza. Izindawo ezipholishiwe zivame ukuthandwa ngenxa yokushelela kwazo kanye nokugcinwa kwazo kalula.

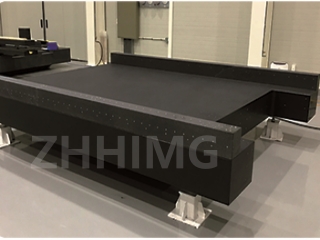

5. Izesekeli Nezici: Cabanga ngezici ezengeziwe njengezikhala ze-T zokubopha, ukulinganisa izinyawo ukuze kuqiniswe, kanye nokutholakala kwezinsizakalo zokulinganisa. Lokhu kungathuthukisa ukusebenza kwepuleti lakho lokuhlola i-granite.

Ngamafuphi, ukukhetha ipuleti lokuhlola i-granite elifanele lomshini wakho we-CNC kudinga ukucatshangelwa ngokucophelela usayizi, ukuthamba, ikhwalithi yezinto ezibonakalayo, ukuqeda ubuso, nezinye izici. Ngokukhetha ipuleti elifanele, ungaqinisekisa ukulinganisa okunembile futhi uthuthukise ukusebenza kahle kokusebenza kwakho komshini.

Isikhathi sokuthunyelwe: Disemba 23-2024