Amapuleti obuso be-granite asetshenziswa kabanzi ekusetshenzisweni komshini wokulungisa ngokunemba, ekukhiqizweni kwe-elekthronikhi, kanye nasezilabhorethri ze-metrology. Njengamathuluzi abalulekile okuhlola nokulinganisa okunembile, ukukhetha ipuleti lobuso be-granite elifanele kubalulekile ukuqinisekisa ukusebenza kwesikhathi eside kanye nokuthembeka kokulinganisa. Nazi izinto ezinhlanu ezibalulekile okufanele uzicabangele lapho ukhetha ipuleti lobuso be-granite:

1. Ikhwalithi Yezinto Ezibonakalayo Ze-Granite

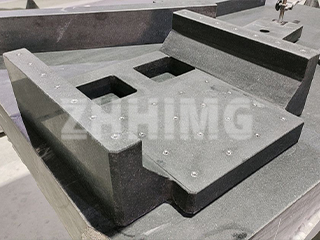

Ikhwalithi yezinto zegranite ithinta ngqo ukunemba kwepulatifomu kanye nobude bayo. Igranite emnyama yemvelo esezingeni eliphezulu, eyaziwa ngobulukhuni bayo, ukuvuleka okuphansi, kanye nokukhula okuncane kokushisa, ikhethwa kakhulu ekusetshenzisweni kwe-metrology. Uma ukhetha ipuleti lobuso begranite, khetha izinto ezinokwakheka okufanayo kwamaminerali, isakhiwo esiminyene, kanye nokuqhekeka okuncane kwangaphakathi noma izikhala. Ubuso obucwebezelisiwe kahle, obungenazo izikhala buyasiza ekumelaneni nokungcola futhi buqinisekisa ukuphindaphindeka okungcono ekulinganisweni okunembile.

2. Izidingo Zosayizi Nokunemba

Ubukhulu bepuleti lobuso kumele bufane nosayizi nesisindo sezinto zokusebenza okufanele zilinganiswe. Amapuleti amakhulu kakhulu angaholela ezindlekweni ezingadingekile futhi athathe isikhala esiningi, kuyilapho amapuleti amancane kakhulu ekhawulela ububanzi bokulinganisa kanye nokuqina. Ukunemba kubaluleke ngokulinganayo—ukuthamba, ukunemba, kanye nobukhulu obuyisikwele kumele kuhlangabezane nesigaba esithile sokubekezelelana esidingekayo kuhlelo lwakho lokusebenza. Amapuleti obuso ngokuvamile ahlukaniswa ngamamaki afana nezindinganiso ze-DIN, GB, noma ze-ASME (Ibanga 0, 1, 2, njll.).

3. Amasu Okuqeda Ubuso

Ukwelashwa kwendawo kuyisici esibalulekile ekunqumeni kokubili ukusetshenziswa kanye nokunemba kwepuleti le-granite. Izinketho ezivamile zokuqeda zifaka phakathi ukugoqa ngesandla, ukugaya ngokunemba, kanye nokupholisha kahle. Ukuqeda okubushelelezi, okufana nesibuko kunciphisa ubulukhuni bendawo futhi kuthuthukisa ukulingana kokulinganisa. Ngokuphambene nalokho, ukuqeda okuvimbela ukushelela njengokuqhumisa isihlabathi kungasetshenziswa ezindaweni lapho ukuzinza kwezingxenye kuyinkinga khona. Futhi, ukukhetha indawo enezakhiwo ezingamelani nokugqwala kusiza ukugcina ubuqotho bobukhulu ngokuhamba kwesikhathi, ikakhulukazi ezindaweni ezinomswakama noma zezimboni.

4. Ukuzinza Kwesakhiwo Nokuqina Kwaso

I-Granite izinzile ngokwemvelo, kodwa akuwona wonke ama-granite asebenza ngokulinganayo ngaphansi kwezimo ezinzima. Ukuqinisekisa ubuqotho besakhiwo, i-plate kumele ibe namandla aphezulu okucindezela, ukumuncwa kwamanzi okuncane, kanye nokumelana okuhle nokushaqeka. Ezindaweni ezinamazinga okushisa ashintshashintshayo, kuyalulekwa ukusebenzisa i-granite ene-coefficient ephansi kakhulu yokwanda kokushisa. Ngaphezu kwalokho, i-plate kumele imelane nokuguguleka kanye nokugqwala kwamakhemikhali ukuze imelane nokusetshenziswa isikhathi eside ngaphandle kokunemba okonakele.

5. Ukusekelwa Kokunakekelwa Nokusekelelwa Ngemva Kokuthengisa

Ngisho namapuleti ongaphezulu e-granite aqinile kakhulu adinga ukunakekelwa njalo ukuze alondoloze ukusebenza okuhle kakhulu. Lapho ukhetha umhlinzeki, funa izinkampani ezinikeza izinsizakalo zokulinganisa, ukwesekwa kobuchwepheshe, kanye nezincwadi zomsebenzisi ezinemininingwane. Izindawo ezilula ukuzihlanza kanye nezinqubo zokulungisa eziqondile kuzosiza ukwandisa impilo yesevisi yepuleti. Ukuhlanza okuvamile, ukuvikelwa kwemvelo, kanye nokulungiswa kabusha ngezikhathi ezithile kubalulekile ukuqinisekisa ukunemba kokulinganisa okuqhubekayo.

Isiphetho

Ukukhetha ipuleti elifanele le-granite surface akukhona nje ukukhetha ibhlogo eliqinile letshe—kuhilela ukucabangela ngokucophelela ikhwalithi yezinto ezibonakalayo, isigaba sokunemba, ukuqeda, ukuzivumelanisa nezimo kwemvelo, kanye nokusekelwa ngemva kokuthenga. Ngokuhlola lezi zici ezinhlanu, ungaqinisekisa ukuthi ipulatifomu yakho ye-granite inikeza ukunemba okuthembekile nokuhlala isikhathi eside kwezidingo zakho zokulinganisa ukunemba.

Isikhathi sokuthunyelwe: Julayi-24-2025