Enkathini yesimanje yobuchwepheshe, imishini ye-CNC isibe yingxenye ebalulekile embonini yokukhiqiza. Isetshenziswa kabanzi emikhakheni eyahlukene ukuze kuhlinzekwe ngokunemba nangokunemba enqubweni yokukhiqiza. Enye yezingxenye ezibalulekile zemishini ye-CNC umbhede we-granite. Ukunemba nokuzinza kombhede we-granite kubalulekile ekusebenzeni kahle kwemishini ye-CNC. Kulesi sihloko, sizoxoxa ngezinyathelo ezibalulekile zokuqinisekisa ukunemba nokuzinza enqubweni yokukhiqiza umbhede we-granite.

Okokuqala, ukukhethwa kwe-granite esezingeni eliphezulu kubalulekile ekuqinisekiseni ukunemba nokuqina kombhede we-granite. I-granite kufanele ibe nokuthungwa okufanayo futhi ingabi nemifantu noma amaphutha. I-granite esezingeni eliphezulu nayo izoba ne-coefficient encane yokwanda kokushisa, okuqinisekisa ukuthi ubukhulu bombhede buhlala buzinzile ngenkathi kudlula izinguquko ezahlukene zokushisa ngesikhathi senqubo yokukhiqiza.

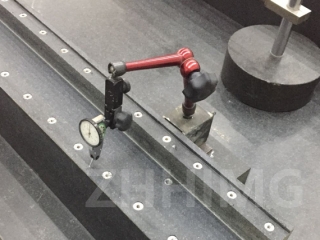

Okwesibili, ukulevelishwa kombhede wegranite kubaluleke kakhulu ekuqinisekiseni ukunemba. Ukunemba kokusicaba kombhede kufanele kube ngaphakathi kwama-micron, futhi kufanele kulevelishwe kusetshenziswa amathuluzi okulinganisa izinga lokunembile. Lokhu kuzoqinisekisa ukuthi imishini ye-CNC isebenza kahle nangokunembile.

Okwesithathu, ukusetshenziswa kwama-bearings anembile embhedeni we-granite kubalulekile ekugcineni ukuzinza ngesikhathi senqubo yokukhiqiza. Ama-bearings kufanele alayishwe kusengaphambili ukuqinisekisa ukuthi noma yimaphi amandla angaphandle awathinti ukuzinza kombhede. Futhi, ama-bearings kufanele abekwe kahle, futhi ukufakwa kwawo kufanele kungabi nokudlidliza.

Okwesine, ukugcinwa kombhede wegranite kubalulekile ekuqinisekiseni ukunemba nokuzinza ngesikhathi senqubo yokukhiqiza. Umbhede kumele uhlanzwe njalo futhi ugcinwe ungenazo inhlabathi noma imfucuza engathinta ukusebenza kwawo. Ngaphezu kwalokho, amabheringi kufanele agcotshwe njalo ukuqinisekisa ukuthi asebenza kahle.

Okokugcina, ithimba elinekhono nelinolwazi kufanele libekwe ukuba liphathe inqubo yokukhiqiza. Kumelwe liqeqeshwe ngokusebenza kwemishini futhi lihlale lihlola ukusebenza kwemishini. Lokhu kuzoqinisekisa ukuthi noma yiziphi izinkinga zitholakala kusenesikhathi futhi zilungiswe ngokushesha.

Ekuphetheni, inqubo yokukhiqiza imibhede yegranite yemishini ye-CNC idinga ukunakwa kwemininingwane kanye nokuqapha okuqhubekayo ukuqinisekisa ukunemba nokuzinza. Kusukela ekukhetheni igranite esezingeni eliphezulu kuya ekunakekelweni okuvamile kanye nokusetshenziswa kwama-precision bearings, inqubo yokukhiqiza ihilela izinyathelo ezahlukahlukene ezibalulekile ezinquma ukusebenza kahle kombhede wegranite. Ngokunakekelwa okufanele nokunakwa, umbhede wegranite unganikeza ukunemba nokunemba kwemishini ye-CNC iminyaka ezayo.

Isikhathi sokuthunyelwe: Mashi-29-2024