Ezindaweni ezifana nokukhiqiza isemiconductor kanye nezisetshenziswa zokulinganisa ukunemba, ukunemba kwezinkundla zokunemba zegwadle kunquma ngokuqondile ikhwalithi yokusebenza yesisetshenziswa. Ukuqinisekisa ukuthi ukunemba kwenkundla kuhlangabezana nezindinganiso, imizamo kufanele yenziwe kusukela ezicini ezimbili: ukutholwa kwezinkomba ezibalulekile kanye nokuhambisana nezinkambiso ezijwayelekile. .

Ukutholwa kwesikhombi esibalulekile: Ukulawulwa kokunemba kwezinhlangothi eziningi

Ukutholwa kokucaba: Ukunquma "ukucaba" kwendiza eyinkomba

I-flatness iyinkomba eyinhloko yamaplathifomu anembayo, futhi ngokuvamile ikalwa ngama-laser interferometers noma amazinga kagesi. I-laser interferometer ingakala ngokunembile ukuguquguquka kwamaminithi endaweni yesikhulumi ngokukhipha i-laser beam nokusebenzisa umgomo wokuphazanyiswa kokukhanya, ngokunemba okufinyelela ileveli ye-sub-micron. Ileveli ye-elekthronikhi ikala ngokunyakaza izikhathi eziningi futhi idweba imephu yekhonta enezinhlangothi ezintathu yendawo yesikhulumi ukuze kutholwe ukuthi akhona yini ama-protrusions asendaweni noma ama-depression. Isibonelo, izinkundla zegwadle ezisetshenziswa emishinini ye-semiconductor photolithography kudingeka ukuthi zibe nesicaba esingu-±0.5μm/m, okusho ukuthi umehluko wobude obungaphakathi kwemitha elingu-1 ubude akufanele udlule uhhafu we-micrometer. Kuphela ngokusebenzisa imishini yokuthola ukunemba okuphezulu lapho leli zinga eliqinile lingaqinisekiswa khona. .

2. Ukutholwa kokuqonda: Qinisekisa "ubuqotho" bokunyakaza okuqondile

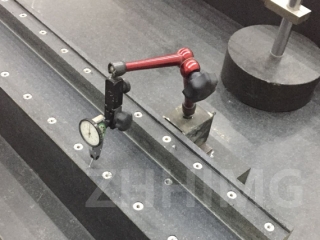

Kumapulatifomu aphethe izingxenye ezihambayo ezinembayo, ukuqondisa kubaluleke kakhulu. Izindlela ezijwayelekile zokutholwa yindlela yocingo noma i-laser collimator. Indlela yocingo ihlanganisa ukumisa izintambo zensimbi ezinemba okuphezulu nokuqhathanisa igebe phakathi kwendawo yesikhulumi nezintambo zensimbi ukuze kunqunywe ubuqotho. I-laser collimator isebenzisa izici zomugqa zokusakaza ze-laser ukuze ithole iphutha lomugqa wendawo yokufaka yesitimela somhlahlandlela. Uma ukuqondisa kungahlangabezani nendinganiso, kuzobangela ukuthi okokusebenza kugudluke phakathi nokunyakaza, kuthinte ukucubungula noma ukunemba kokulinganisa. .

3. Ukutholwa kokuqina kobuso: Qinisekisa "ukulunga" kokuxhumana

Ubukhulu obungaphezulu beplatifomu buthinta ukulingana kokufakwa kwengxenye. Ngokuvamile, imitha ye-stylus roughness noma i-optical microscope isetshenziselwa ukutholwa. Insimbi yohlobo lwe-stylus irekhoda izinguquko zobude bephrofayela encane ngokuthinta indawo yesikhulumi nge-probe emihle. Imakroskopu yamehlo ingabona ngokuqondile ukuthungwa kwendawo. Kuzinhlelo zokusebenza ezinemba okuphezulu, ubulukhuni obungaphezulu bezinkundla zegwadle budinga ukulawulwa ku-Ra≤0.05μm, okulingana nomthelela ofana nesibuko, kuqinisekiswe ukuthi izingxenye ezinembayo zilingana ngokuqinile phakathi nokufakwa nokugwema ukudlidliza noma ukususwa okubangelwa izikhala. .

Amazinga anembayo alandela: imikhuba yamazwe ngamazwe kanye nokulawula kwangaphakathi kwebhizinisi

Njengamanje, emazweni ngamazwe, amazinga e-ISO 25178 kanye ne-GB/T 24632 avame ukusetshenziswa njengesisekelo sokunquma ukunemba kwamapulatifomu egwadle, futhi kunezigaba ezicacile zezinkomba ezifana nokucaba nokuqondile. Ngaphezu kwalokho, amabhizinisi akhiqizayo asezingeni eliphezulu avame ukubeka izindinganiso zokulawula zangaphakathi eziqinile. Isibonelo, imfuneko yokucaba kweplathifomu yegwadle yomshini we-photolithography iphakeme ngo-30% kunezinga lamazwe ngamazwe. Lapho wenza izivivinyo, idatha elinganisiwe kufanele iqhathaniswe namazinga ahambisanayo. Izinkundla kuphela ezithobelana ngokugcwele namazinga ezingaqinisekisa ukusebenza okuzinzile kumishini enembayo. .

Ukuhlola ukunemba kwezinkundla zegwadle kuyiphrojekthi ehlelekile. Kuphela ngokuhlola ngokuqinile izinkomba eziwumongo ezifana nokucaba, ubuqotho, nobulukhuni bendawo, nokunamathela ezindinganisweni zamazwe ngamazwe nezebhizinisi, kungaqinisekiswa ukunemba okuphezulu nokuthembeka kwenkundla, ukubeka isisekelo esiqinile sezinkambu zokukhiqiza ezisezingeni eliphezulu njengama-semiconductors namathuluzi anembayo.

Isikhathi sokuthumela: May-21-2025