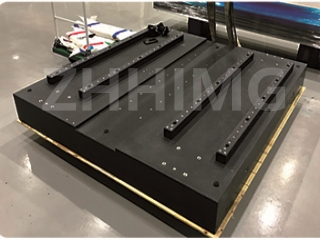

I-Granite ingenye yezinto ezivame kakhulu ezisetshenziselwa isisekelo samathuluzi omshini we-CNC ngenxa yokuqina kwayo okuhle kakhulu, ukuqina, nokunemba. Kodwa-ke, ukudlidliza nomsindo kungenzeka ngesikhathi sokusebenza kwemishini ye-CNC, okungaba nomthelela omubi ekusebenzeni nokunemba komshini. Kulesi sihloko, sizoxoxa ngezindlela zokunciphisa ukudlidliza nomsindo lapho isisekelo segwadle sisetshenziselwa amathuluzi omshini we-CNC.

1. Ukufakwa Okufanelekile

Enye yezinto ezibaluleke kakhulu okufanele icatshangelwe lapho usebenzisa isisekelo segwadle sethuluzi lomshini we-CNC ukufakwa ngendlela efanele. Isisekelo segwadle kufanele silinganiswe futhi sivikelwe ngokuqinile phansi ukuze kuvinjelwe noma yikuphi ukunyakaza okungabangela ukudlidliza. Uma ufaka isisekelo se-granite, ama-anchor bolts noma i-epoxy grout ingasetshenziswa ukuze ivikeleke phansi. Isisekelo kufanele futhi sihlolwe ngezikhathi ezithile ukuze kuqinisekiswe ukuthi sihlala sisezingeni futhi sivikelekile.

2. Isolation Mats

Esinye isisombululo esisebenzayo sokunciphisa ukudlidliza nomsindo ukusebenzisa amacansi okuzihlukanisa. Lamacansi aklanyelwe ukumunca ukudlidliza nokushaqeka futhi angabekwa ngaphansi komshini ukuze kuncishiswe ukudluliswa kokudlidliza phansi nasezindaweni ezizungezile. Ukusetshenziswa kwamata okuhlukanisa kungathuthukisa kakhulu ukusebenza nokunemba komshini ngenkathi kunciphisa umsindo ongafuneki.

3. Ukudambisa

I-Damping yindlela ehlanganisa ukungeza izinto emshinini ukunciphisa ukudlidliza nomsindo okungafuneki. Le nqubo ingasetshenziswa kusisekelo se-granite ngokusebenzisa izinto ezifana nerabha, ukhokho, noma igwebu. Lezi zinto zingafakwa phakathi kwesisekelo nomshini ukunciphisa ukudlidliza nomsindo. Okudizayinelwe kahle futhi kwabekwa okokumanzi kunganciphisa ngempumelelo ukuvela kwamaza azwakalayo angabangela ukudlidliza emshinini.

4. Ukusebenzisa Amathuluzi Okulinganiselayo

Ukusebenzisa amathuluzi okulinganiselayo kubalulekile ekunciphiseni ukudlidliza nomsindo. Izibambi zamathuluzi kanye ne-spindle yethuluzi lomshini we-CNC kufanele zilinganiswe ukuze kugwenywe ukudlidliza okweqile ngesikhathi sokusebenza. Amathuluzi angalinganiseli angabangela ukudlidliza okukhulu okungaba nomthelela omubi ekusebenzeni nokunemba komshini. Ukugcina isistimu yamathuluzi elinganiselayo kunganciphisa kakhulu ukwenzeka kokudlidliza okungafuneki nomsindo ethuluzini lomshini we-CNC.

Isiphetho

Ukusebenzisa isisekelo se-granite samathuluzi omshini we-CNC kuyisinqumo esihle kakhulu sokuzinza nokunemba. Kodwa-ke, ukudlidliza nomsindo kungenzeka ngesikhathi sokusebenza komshini. Ngokulandela amasu ashiwo ngenhla, unganciphisa ngempumelelo ukudlidliza nomsindo. Ukufakwa kahle, omata bokuhlukanisa, ukumanzisa, nokusebenzisa amathuluzi alinganiselayo kuyizindlela ezisebenzayo zokufinyelela ukusebenza okushelelayo nokuthule kwemishini ye-CNC kuyilapho kugcinwa amazinga aphezulu okunemba.

Isikhathi sokuthumela: Mar-26-2024