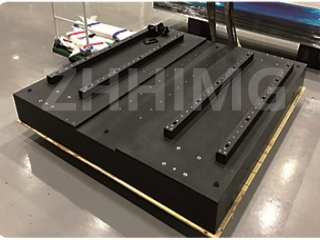

Izingxenye zegranite zidlala indima ebalulekile enkambisweni yokukhiqiza i-semiconductor. Lezi zingxenye zisekela imishini esindayo, zihlinzeka ngeplatifomu ezinzile yokukhiqizwa kwe-wafer, futhi ziqinisekisa ukunemba kwayo yonke inqubo yokukhiqiza. Kodwa-ke, ngokuhamba kwesikhathi, izingxenye zegranite zingalimala ngenxa yokusetshenziswa njalo, izici zemvelo noma ukuphathwa okungafanele ngesikhathi sokulungiswa. Ukulimala kwezingxenye zegranite kungaholela ekwehleni kokunemba, okungathinta ikhwalithi yomkhiqizo wokugcina. Ngakho-ke, kubalulekile ukulungisa ukubukeka kwezingxenye zegranite ezonakele nokulungisa kabusha ukunemba kwazo.

Isinyathelo sokuqala ekulungiseni ukubukeka kwezingxenye ze-granite ukuhlola ubukhulu bomonakalo. Ukuklwebheka kobuso, ama-chips, kanye nemifantu kuyizinhlobo ezivamile zomonakalo ezingaxazululwa kalula. Kodwa-ke, umonakalo omkhulu njengokugoba, ukugoba noma ukuqhekeka ngaphansi kobuso kungadinga ubuchwepheshe bochwepheshe ukulungisa. Uma ubukhulu bomonakalo sebuhlolwe, uhlelo lokusebenza lungatholakala.

Uma kunomonakalo omncane, isinyathelo sokuqala ukuhlanza ubuso bengxenye yegranite ngesihlanzi esingagugi. Lesi sinyathelo siyadingeka ukuze kususwe noma yikuphi ukungcola, imfucumfucu, noma amafutha angaphazamisa inqubo yokulungisa. Okulandelayo, ungasebenzisa i-fine-grit diamond polishing pad ukuze ususe imihuzuko ebusweni futhi ubuyisele ukukhanya kwasekuqaleni kwengxenye. Uma kwenzeka ama-chips noma imigodi, ukuwagcwalisa nge-epoxy resin enombala ofanelana nombala wegranite, kungaba usizo ekubuyiseleni ukubukeka kwengxenye.

Uma kunomonakalo omkhulu kakhulu, kungadingeka izinsizakalo zokulungisa zobungcweti. Uchwepheshe wokulungisa ubungcweti angalungisa umonakalo futhi abuyisele ukubukeka kwengxenye. Bangaphinde bapholishe noma balolonge indawo ukuze babuyisele ukuqeda kwasekuqaleni, ngaleyo ndlela basuse noma yimiphi imihuzuko noma amamaki ashiywe yinqubo yokulungisa. Le nqubo idinga imishini ekhethekile, futhi kubalulekile ukukhetha umhlinzeki wesevisi yokulungisa onedumela elihle futhi onolwazi.

Uma ukubukeka kwengxenye sekubuyiselwe, ukulinganiswa kabusha kokunemba kuyadingeka. Ukulinganiswa okunembile kuyisihluthulelo sokuqinisekisa ukunemba enkambisweni yokukhiqiza i-semiconductor. Noma yikuphi ukuphambuka ekunembeni okudingekayo kungaholela emiphumeleni eyinhlekelele njengokwehluleka kwezingxenye noma ukugijima okuphelele kokukhiqiza. Imishini yokulinganisa efanele kufanele isetshenziswe ukuhlola ukunemba kwengxenye ye-granite. Uma kwenzeka ukuphambuka ekunembeni okulindelekile, kufanele kuthathwe izinyathelo zokulungisa ukuze kuyibuyisele ezingeni elidingekayo.

Ekuphetheni, ukunakekela izingxenye ze-granite kubalulekile ekugcineni ukunemba kwenqubo yokukhiqiza i-semiconductor. Ukulungisa ukubukeka kwezingxenye nokulungisa ukunemba kwazo kungasiza ekugwemeni noma yikuphi ukuwohloka kokusebenza nokuqinisekisa ukusebenza kahle. Kubalulekile ukulandela isheduli yokulungisa ejwayelekile futhi uthathe isinyathelo ngokushesha noma nini lapho konakala khona. Ukugcinwa kahle kwezingxenye ze-granite kuwukutshalwa kwezimali kwesikhathi eside okungasiza ekuthuthukiseni ukusebenza kahle kanye nekhwalithi yokukhiqiza iyonke.

Isikhathi sokuthunyelwe: Disemba-05-2023