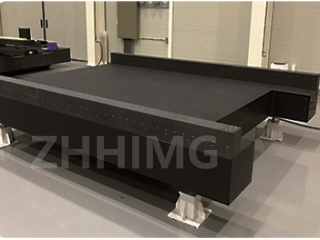

Izisekelo zomshini we-granite ziyingxenye ebalulekile emikhiqizweni eminingi ye-Automation Technology. Zihlinzeka ngesisekelo esiqinile nesiqinile semishini yokusebenza futhi ziqinisekisa ukunemba nokusebenza kahle kwayo. Kodwa-ke, njenganoma yimuphi omunye umshini, zidinga ukusetshenziswa nokugcinwa okufanele ukuze zisebenze kahle futhi zandise isikhathi sazo sokuphila.

Nazi ezinye izeluleko zokuthi ungazisebenzisa kanjani futhi uzinakekele kanjani izisekelo zomshini we-granite zemikhiqizo ye-Automation Technology:

1. Ukufakwa okufanele: Qinisekisa ukuthi isisekelo somshini sifakwe kahle. Isisekelo kufanele sibe nendawo eqondile nezinzile ukuvimbela noma yikuphi ukuphambuka ngesikhathi sokusetshenziswa. Kubalulekile ukulandela imiyalelo yomenzi yokufaka nokulinganisa.

2. Ukuhlanza njalo: Ukuhlanza njalo kubalulekile ukuze kugcinwe ukuhlanzeka kwesisekelo somshini we-granite nokuvimbela ukunqwabelana kokungcola noma imfucumfucu. Kunconywa ukusebenzisa ibhulashi elithambile noma indwangu ukusula izinhlayiya zomphezulu. Gwema amakhemikhali anamandla angase agqwale noma aklwebhe umphezulu.

3. Ukuhlolwa okuvamile: Hlola isisekelo somshini njalo ukuze ubone ukuthi kukhona yini izimpawu ezibonakalayo zokuguguleka noma ukulimala, njengokuqhekeka noma ama-chips. Uma uthola noma yimuphi umonakalo onjalo, yazisa uchwepheshe oqeqeshiwe ukuthi alungise isisekelo noma asishintshe ngesinye esisha.

4. Qapha izinga lokushisa: Izisekelo zomshini we-granite zizwela ukushintshashintsha kwezinga lokushisa okukhulu. Gwema ukubeka isisekelo emazingeni okushisa aphezulu ukuze uvimbele ukuphambuka noma ukugoba. Gcina izinga lokushisa lingaguquki endaweni ezungezile, bese usebenzisa uhlelo lokupholisa uma kudingeka.

5. Gwema ukucindezela ngokweqile: Ungalokothi ugcwalise isisekelo somshini ngesisindo noma ukucindezela ngokweqile. Ukulayisha ngokweqile kungaholela ekuqhekekeni, kuma-chips, noma komunye umonakalo. Hlala unamathela emikhawulweni yomthwalo enconyiwe enikezwe umenzi.

6. Ukugcotshwa: Ukugcotshwa kuyadingeka ukuze kugcinwe isisekelo somshini we-granite sisebenza kahle. Hlola izincomo zomenzi mayelana nokugcotshwa noma uxhumane nochwepheshe ochwepheshe. Qiniseka ukuthi ulandela uhlelo olunconyiwe lokugcotshwa.

7. Ukulinganisa okuvamile: Ukulinganisa kubalulekile ukuqinisekisa ukuthi isisekelo somshini kanye nezingxenye zisebenza ngaphakathi kokubekezelelana okudingekayo. Ukulinganisa okuvamile kuzoqinisekisa ukusebenza okunembile futhi kwandise isikhathi sokuphila kwesisekelo somshini.

Ekuphetheni, izisekelo zomshini we-granite ziyizingxenye ezibalulekile emikhiqizweni ye-Automation Technology. Ukusetshenziswa kahle nokugcinwa njalo kwalezi zisekelo kuzoqinisekisa ukuthi zihlala isikhathi eside futhi zisebenza kahle. Landela amathiphu anikezwe ngenhla ukuze ulondoloze isisekelo somshini semikhiqizo ye-Automation Technology, futhi uzojabulela isevisi enhle kakhulu evela kuzo.

Isikhathi sokuthunyelwe: Jan-03-2024