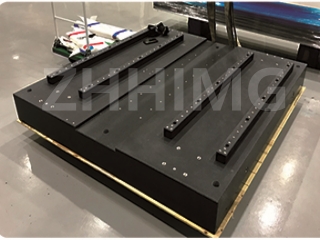

Isisekelo somshini we-granite semikhiqizo yezinsimbi zokulinganisa ubude be-Universal siyinto ebalulekile enikeza isisekelo esiphelele sokulinganisa okunembile. I-granite, eyaziwa ngamandla ayo aphezulu nokuqina kwayo, iyinto efanelekile yezinsimbi zomshini, ikakhulukazi ezimbonini ezidinga ukulinganisa okucophelelayo njengobunjiniyela bemishini, izindiza, kanye nezimoto. Lezi zinsimbi zomshini zinikeza ukuzinza okuphezulu kanye nokuqina kokushisa, okuqinisekisa ukunemba kokulinganisa. Nazi ezinye iziqondiso ezibalulekile zokusebenzisa nokugcina izisekelo zomshini we-granite zemikhiqizo yezinsimbi zokulinganisa ubude be-Universal.

1. Iziqondiso Zokufaka

Kubalulekile ukuqinisekisa ukuthi isisekelo somshini we-granite sifakwe kahle. Isisekelo kumele silinganiswe futhi siboshwe phansi ngaphambi kokuba kubekwe ithuluzi lokulinganisa ubude be-Universal kuso. Isisekelo somshini kumele sibekwe endaweni engenawo amandla okudlidliza ukuqinisekisa izilinganiso ezinembile.

2. Ukuhlanza Nokunakekela

Isisekelo somshini we-granite semikhiqizo yezinsimbi zokulinganisa ubude be-Universal kumele sihlanzwe futhi sigcinwe njalo ukuze kugcinwe ukusebenza kahle. Gwema ukusebenzisa izinto zokuhlanza ezinzima ezingalimaza ubuso be-granite. Esikhundleni salokho, insipho ethambile noma isisombululo sokuhlanza kufanele sisetshenziswe ukuhlanza ubuso besisekelo somshini. Ukuhlanza kufanele kwenziwe ngezikhathi ezithile kuye ngokuthi kusetshenziswe kangaki.

3. Gwema Isisindo Esiningi Nemiphumela

Izisekelo zomshini we-granite zinikeza ukuzinza okuphezulu, kodwa zinemingcele yazo. Kubalulekile ukugwema ukubeka izinsimbi eziningi kakhulu esisekelweni somshini, njengoba lokhu kungaholela ekugobeni noma ekuqhekekeni kobuso be-granite. Ngokufanayo, imithelela esisekelweni somshini kumele igwenywe ngoba ingabangela nomonakalo.

4. Ukulawula Izinga Lokushisa

Izisekelo zomshini we-granite ziyazwela ekushintsheni kwezinga lokushisa. Kubalulekile ukuqinisekisa ukuthi izinga lokushisa egumbini lapho kufakwe khona isisekelo somshini liyalawulwa. Gwema ukubeka isisekelo somshini ezindaweni lapho kunokushintshashintsha kwezinga lokushisa, njengezindawo eziseduze namafasitela noma ama-skylight.

5. Ukuthambisa

Ithuluzi lokulinganisa ubude elisetshenziswa yi-Universal elibekwe esisekelweni somshini we-granite lidinga ukunyakaza okubushelelezi. Ukugcoba kufanele kwenziwe njalo ukuqinisekisa ukuthi izingxenye ezihambayo zomshini zisebenza kahle ngaphandle kokungqubuzana. Kodwa-ke, kubalulekile ukugwema ukugcoba ngokweqile, njengoba kungabangela ukuthi uwoyela uqoqeke esisekelweni somshini, okudala ingozi yokungcola.

6. Ukulinganisa Okuvamile

Ukulinganisa kuyisici esibalulekile sokugcina izilinganiso ezinembile. Ukuhlolwa kokulinganisa okuvamile kumele kwenziwe ukuqinisekisa ukuthi izilinganiso ziyahambisana futhi zinembile. Ukuvama kokulinganisa kuncike ekuvameni kokusetshenziswa, kodwa izimboni eziningi zidinga ukuhlolwa kokulinganisa kwenziwe okungenani kanye ngonyaka.

Ekuphetheni

Isisekelo somshini we-granite semikhiqizo yezinsimbi zokulinganisa ubude be-Universal siyinto ebalulekile edinga ukunakekelwa nokugcinwa okufanele ukuze kufezwe ukusebenza okuhle kakhulu. Iziqondiso ezishiwo ngenhla zibalulekile kunoma ubani ofuna ukusebenzisa nokugcina isisekelo somshini wakhe we-granite kahle. Ngokufakwa okufanele, ukuhlanza nokugcinwa njalo, ukulawulwa kwezinga lokushisa, ukugcotshwa okwanele, kanye nokuhlolwa okuvamile kokulinganisa, abasebenzisi bangaqiniseka ukuthi ithuluzi labo lokulinganisa ubude be-Universal lizoletha imiphumela enembile nehambisanayo iminyaka ezayo.

Isikhathi sokuthunyelwe: Jan-22-2024