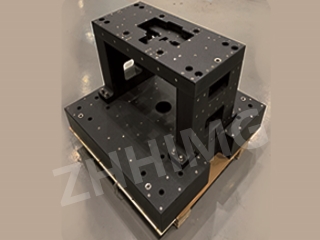

Ukuhlanganiswa kwe-Granite kuyisici esibalulekile ezinqubweni zokukhiqiza ze-semiconductor. Umhlangano uvame ukusetshenziswa njengesisekelo sokwakhiwa kwemishini enembayo esetshenziswa ekukhiqizeni ama-semiconductors. Lokhu kungenxa yezinzuzo ezihlukile kanye nezakhiwo ze-granite, okwenza kube yinto ekahle yalolu hlelo lokusebenza.

I-Granite ithandwa kakhulu ekukhiqizeni i-semiconductor ngenxa yokuqina kwayo okuphezulu, ukuzinza kwe-thermal, ukuqina okuhle kakhulu kwe-dimensional, kanye ne-coefficient ephansi yokwanda okushisayo. Lezi zakhiwo zenza i-granite Assembly ibe into efanelekile yohlelo lokusebenza olunembayo oludinga amazinga aphezulu okunemba, njengemishini yokucubungula i-wafer ye-semiconductor.

Ezinqubweni zokukhiqiza ama-semiconductor, ukusetshenziswa kokuhlanganiswa kwe-granite kuqinisekisa ukuqondanisa okunembayo kanye nokuma kwezingxenye zemishini ehlukahlukene, njengama-wafers, amagumbi okuhlanza, namathuluzi okucubungula. Lokhu kubalulekile ukuze kuzuzwe izinga elidingekayo lokunemba elidingekayo ekwenziweni kwe-semiconductor.

Enye inzuzo ebalulekile yokuhlanganiswa kwe-granite yikhono layo lokugcina ukuma nobukhulu bayo phezu kwezinhlobonhlobo zamazinga okushisa. Lokhu kubalulekile embonini ye-semiconductor, lapho amazinga okushisa aphezulu asetshenziswa ezigabeni ezahlukahlukene zokwenziwa kwemishini.

Ngaphezu kwalokho, ukuhlanganiswa kwe-granite kunikeza ukumelana okuhle kakhulu kokuguga, okwenza kube yinto ehlala isikhathi eside futhi ehlala isikhathi eside yezingxenye zemishini.

Sengiphetha, ukusetshenziswa kokuhlanganiswa kwe-granite ezinqubweni zokukhiqiza ze-semiconductor kubalulekile ukuze kuqinisekiswe ukukhiqizwa kwama-semiconductors ekhwalithi ephezulu. Izici zayo ezihlukile, ezinjengokuqina okuphezulu, ukuzinza kwe-thermal, nokuzinza kwe-dimensional, ziyenza ibe inketho efanelekile yezinhlelo zokusebenza ezinembayo. Ngaphezu kwalokho, ukuqina nokumelana nokuguga kuqinisekisa ukuthi izingxenye zemishini eyenziwe ngokuhlangana kwegwadle zizohlala isikhathi eside, kunciphise izindleko zokuyilungisa. Ngakho-ke, abakhiqizi kufanele baqhubeke nokusebenzisa le nto ukuze baqinisekise amazinga aphezulu okunemba nokuthembeka ezinqubweni zabo zokukhiqiza ama-semiconductor.

Isikhathi sokuthumela: Dec-06-2023