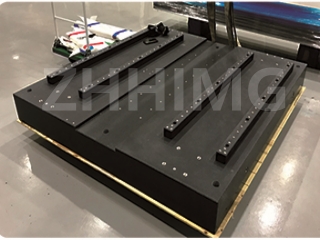

I-Granite iyinto ethandwayo yesisekelo semishini yokucubungula i-laser ngenxa yokuqina kwayo okuhle kakhulu, ukuqina, nokumelana nokudlidliza. I-Granite inokuminyana okuphezulu kanye ne-porosity ephansi kunezinsimbi eziningi, okwenza ingathinteki ekukhuleni nasekufinyezeni okushisayo, okuqinisekisa ukunemba okukhulu nokuzinza ngesikhathi sokucubungula nge-laser. Kulesi sihloko, sizoxoxa ngendlela yokusebenzisa isisekelo se-granite sokucubungula nge-laser ngokuningiliziwe.

1. Ukukhetha uhlobo olulungile lwegwadle

Lapho ukhetha isisekelo se-granite sokucutshungulwa kwe-laser, kubalulekile ukukhetha uhlobo olulungile lwegwadle olunezici ezifanele zokusetshenziswa okuhlosiwe. Izinto okufanele zicatshangelwe zihlanganisa:

- I-Porosity - khetha i-granite ene-porosity ephansi ukuze ugweme ukungena kwamafutha, uthuli, nomswakama.

- Ukuqina - khetha uhlobo lwegwadle eliqinile njenge-Black Galaxy noma i-Absolute Black, enobulukhuni be-Mohs obuphakathi kuka-6 no-7, okubenza bumelane nokuguga nokudabuka ekusebenziseni okuvamile.

- Ukuzinza kwe-thermal - bheka izinhlobo zegwadle ezine-coefficient ephezulu yokushisa ehlinzeka ngokuzinza okuhle kakhulu kokushisa ngesikhathi sokucubungula i-laser.

2. Ukuqinisekisa ukuthi isisekelo se-granite sisezingeni futhi sizinzile

Imishini yokucubungula i-laser izwela kakhulu, futhi noma yikuphi ukuchezuka kancane endaweni esezingeni kungabangela ukunemba komkhiqizo wokugcina. Ngakho-ke, kubalulekile ukuqinisekisa ukuthi isisekelo se-granite okugxunyekwe kuso silinganiselwe futhi sizinzile. Lokhu kungafezwa ngokusebenzisa okokusebenza okunembayo kokulinganisa ukuze uhlole futhi ulungise izinga lesisekelo bese usilungisa endaweni usebenzisa amabhawudi noma i-epoxy.

3. Ukugcina isisekelo se-granite sihlanzekile kanye nomswakama

Ukugcina ukuhlanzeka kanye nokuswakama kwesisekelo segwadle kubalulekile ukuze kuqinisekiswe ukuphila kwayo isikhathi eside nokusebenza kwayo. I-Granite isengozini yokuba namabala, futhi noma iyiphi insalela noma ukungcola okungaphezulu kungase kube nomthelela omubi ekusebenzeni kwemishini yokucubungula i-laser. Ngakho-ke, kubalulekile ukugcina isisekelo sihlanzekile futhi singenawo udoti ngokulandela izinqubo zokuhlanza ezituswa ngumenzi.

Ukwengeza, i-granite iyazwela ezinguqukweni zomswakama, futhi ukuchayeka isikhathi eside kumazinga womswakamo aphezulu kungabangela ukuba inwebeke. Lokhu kungabangela izinkinga zokuqondanisa imishini, okuholela ezinkingeni zokunemba komkhiqizo. Ukuze ugweme lezi zinkinga, kunconywa ukugcina amazinga womswakamo cishe ku-50% ngenkathi ugcina okokusebenza kanye nesisekelo segwadle.

4. Ukuqinisekisa ukungena komoya okwanele kwesisekelo segwadle

Ngesikhathi sokucutshungulwa kwe-laser, okokusebenza kukhiqiza ukushisa okufanele kuchithwe. Ngakho-ke, isisekelo se-granite kufanele sibe nomoya owanele ukuvimbela ukushisa ngokweqile. Lokhu kungafezwa ngokufaka amafeni okungenisa umoya noma amapayipi aqondisa umoya oshisayo kude nezinto zokusebenza.

Sengiphetha, ukusebenzisa isisekelo se-granite sokucubungula i-laser kuyisinqumo esihle kakhulu ngenxa yokuqina kwayo okuphezulu, ukuzinza kanye nokumelana nokudlidliza. Kodwa-ke, kubalulekile ukukhetha uhlobo olulungile lwegwadle, uqinisekise ukuthi isisekelo silinganisiwe futhi sizinzile, sigcine amazinga okuhlanzeka kanye nomswakamo, futhi sinikeze umoya wokungena komoya owanele ukuze kuqinisekiswe ukusebenza kahle. Ngokunakekelwa okufanele nokugcinwa kahle, isisekelo se-granite singanikeza isisekelo esizinzile nesiqinile semishini yokucubungula i-laser iminyaka eminingi ezayo.

Isikhathi sokuthumela: Nov-10-2023