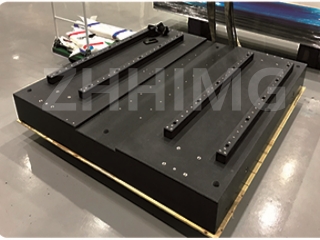

I-Granite iyinto eyenzeka ngokwemvelo esetshenziswa kabanzi embonini yokukhiqiza izisekelo zemishini. Izisekelo zemishini ye-granite zaziwa ngokuzinza kwazo okuphezulu, ukuqina, kanye nezakhiwo ezinhle kakhulu zokudambisa ukudlidliza, okwenza zibe ukukhetha okuhle kwezinhlelo zokusebenza zemishini ezinembe kakhulu. Enye yezicelo ezinjalo lapho izisekelo zemishini ye-granite zivame ukusetshenziswa khona amadivayisi okuhlola amaphaneli e-LCD, asetshenziselwa ukuthola nokuhlaziya amaphutha kumaphaneli e-LCD ngaphambi kokuba ahlanganiswe abe amadivayisi kagesi.

Ukwakhiwa nokwakhiwa kwedivayisi yokuhlola iphaneli ye-LCD kudinga izinga eliphezulu lokunemba, ukuzinza, kanye nokunemba. Noma yikuphi ukudlidliza noma ukunyakaza ngesikhathi sokuhlolwa kwephaneli kungabangela amaphutha okulinganisa, okungaholela emiphumeleni enganembile kanye namaphutha okukhiqiza abizayo. Ukusetshenziswa kwesisekelo somshini we-granite kungasiza ekuqedeni lezi zinkinga futhi kuthuthukise ukusebenza kanye nokunemba kwedivayisi yokuhlola. Nazi ezinye izindlela zokusebenzisa izisekelo zomshini we-granite ngempumelelo kudivayisi yokuhlola iphaneli ye-LCD:

1. Sebenzisa izisekelo zomshini we-granite ezisezingeni eliphezulu

Ukuqinisekisa ukunemba nokuzinza kwedivayisi yokuhlola, kubalulekile ukusebenzisa izisekelo zomshini we-granite ezisezingeni eliphezulu, ezikhiqizwa ngezindinganiso eziqinile. I-granite esetshenziswa esisekweni somshini kufanele ibe sezingeni eliphezulu futhi ingabi nemifantu noma ezinye iziphambeko ezingathinta ukusebenza kwayo. Ubuso besisekelo somshini kufanele bube yisicaba futhi bulingane, kungabi nama-undulation noma ama-bumps angabangela ukungazinzi ngesikhathi senqubo yokuhlola.

2. Hlela umklamo wesisekelo somshini

Umklamo wesisekelo somshini kufanele uhlelwe ngokucophelela, kucatshangelwa ubukhulu bamaphaneli e-LCD azohlolwa, uhlobo lwemishini yokuhlola, kanye nendawo edingekayo ukuze opharetha basebenze. Isisekelo somshini kufanele sakhiwe ukuze sinikeze ukuzinza okuphezulu futhi sinciphise noma yikuphi ukudlidliza noma ukunyakaza ngesikhathi senqubo yokuhlola. Isisekelo kufanele sibe sikhulu ngokwanele ukuze sithwale amaphaneli e-LCD ngokunethezeka futhi sivumele ukufinyelela kalula emishinini yokuhlola.

3. Cabanga ngokungeza izinto zokunciphisa ukudlidliza

Kwezinye izimo, ukusetshenziswa kwezinto zokudambisa ukudlidliza, njengerabha noma i-cork, kungadingeka ukuze kuncishiswe noma yikuphi ukudlidliza noma ukunyakaza ngesikhathi senqubo yokuhlola. Lezi zinto zingangezwa esisekelweni somshini noma phakathi kwemishini yokuhlola kanye nesisekelo ukusiza ukumunca noma yikuphi ukushaqeka noma ukudlidliza. Ukwengezwa kwezinto ezinjalo kungasiza ekuthuthukiseni ukunemba kanye nokuthembeka kwedivayisi yokuhlola.

4. Ukunakekelwa njalo

Ukugcinwa njalo kwesisekelo somshini kubalulekile ukuqinisekisa ukuthi sihlala sisesimweni esihle futhi sisebenza kahle kakhulu. Isisekelo somshini kufanele sihlanzwe njalo ukuze kususwe noma yikuphi ukungcola noma imfucumfucu engathinta ukusebenza kahle. Noma yikuphi ukuqhekeka noma okunye ukukhubazeka kufanele kulungiswe ngokushesha ukuqinisekisa ukuthi isisekelo somshini sihlala sizinzile futhi sithembekile.

Ekuphetheni, ukusetshenziswa kwezisekelo zomshini we-granite kungathuthukisa kakhulu ukusebenza kanye nokunemba kwamadivayisi okuhlola amaphaneli e-LCD. Ngokukhetha i-granite esezingeni eliphezulu nokuhlela ngokucophelela ukwakheka kwesisekelo somshini, ukwengeza izakhi zokunciphisa ukudlidliza lapho kudingeka khona kanye nokugcinwa njalo kuzoholela ekukhiqizweni okuthuthukisiwe ngenkathi kunciphisa amaphutha okukhiqiza.

Isikhathi sokuthunyelwe: Novemba-01-2023