Imishini ye-CNC iguqule umhlaba wokukhiqiza nokucubungula ngobuchwepheshe bayo obuthuthukisiwe obunikeza imisebenzi eqondile nenembile. Iyithuluzi elibalulekile ezimbonini ezahlukahlukene, kufaka phakathi izindiza, izimoto, kanye nezokwelapha, phakathi kwezinye. Enye yezingxenye ezibalulekile zemishini ye-CNC umbhede, osebenza njengesisekelo somshini. Nakuba izinto eziningi zitholakala ukudala umbhede we-CNC, i-granite ivele njengenye yezinketho ezikhethwa kakhulu ngezizathu eziningi.

I-Granite iyinto yemvelo eqinile futhi eqinile enikeza ukuzinza okuhle kakhulu nokuqina kwemishini ye-CNC uma kuqhathaniswa nezinye izinto ezifana nensimbi ephonswe noma insimbi. Njengoba i-granite iyinto yemvelo, imelana nokugqwala nokuwohloka kangcono kunezinye. Ngaphezu kwalokho, igcina ukunemba kwayo nokusebenza kwayo isikhathi eside, okwenza kube ukukhetha okuhle kokusetshenziswa isikhathi eside.

Ngaphandle kwamandla ayo ahlala isikhathi eside, i-granite iye yaqashelwa ngezakhiwo zayo ezihlukile zokushisa. I-granite inokukhula okuphansi kokushisa, okuvumela ukuthi igcine ukuzinza kwayo okulinganayo, ngisho nasemazingeni okushisa aphezulu. Lokhu kusho ukuthi amathuba okuphambuka kokushisa noma ukungazinzile ngesikhathi sokusebenza ancishiswa kakhulu, okusekela ukunemba nokunemba komshini. Impahla yokumunca ukushisa ye-granite nayo iyasiza ekusakazeni ukushisa kude nomshini futhi inciphise amathuba okuhlukahluka kokushisa.

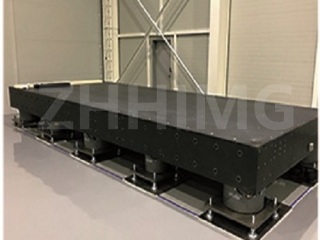

Umbhede we-CNC empeleni uyisisekelo somshini. Ngakho-ke, kubalulekile ukucabangela ukudlidliza, ukuqina, kanye nokuzinza kombhede lapho uwenza. Ngemibhede ye-granite, uthola zonke lezi zici ngobuningi obukhulu, ngenxa yokuqina okukhulu kwe-granite kanye nezakhiwo zokudambisa ukudlidliza. Ngokukhethekile, ine-coefficient ephezulu yokudambisa, evimbela ukudlidliza futhi inciphise umthelela wayo emshinini.

Enye inzuzo ebalulekile yemibhede yegranite ukunemba kwayo kanye nokuphindaphindeka kwayo. Imibhede yegranite inezinga eliphezulu lokusicaba kanye nokugoba okuncane, okwenza ibe yindawo ekahle kakhulu yokugaya, ukugaya, kanye nokusetshenziswa kokubhoboza. Ukusebenza komshini kuncike ekhonweni layo lokugcina ukunemba kwayo kanye nokuphindaphindeka kwayo. Lokhu kungenzeka ngemibhede yegranite ngenxa yokuqina kwayo okungokwemvelo, okusekela ukusebenza okunembile nokuphelele.

Ekuphetheni, imibhede yegranite inikeza izinzuzo eziningi eziyingqayizivele emishinini ye-CNC, okuhlanganisa ukuzinza okumangalisayo, ukuqina, kanye nokumelana nokushisa, okuholela ekunembeni nasekuqondeni okungcono. Izakhiwo ezihlukile zale nto ziyenza ifaneleke ukusetshenziswa isikhathi eside, ngaleyo ndlela yonge izindleko kanye nokugcinwa. Njengoba kunikezwe izidingo zokusebenza okuphezulu kwemishini ye-CNC, umbhede wegranite unikeza isisekelo esihle kakhulu sokuqina komshini, ukunemba, kanye nokuphindaphindwa. Ngakho-ke, uma ufuna umbhede wekhwalithi ephezulu wemishini yakho ye-CNC, igranite kufanele ibe yisinqumo sakho sokuqala.

Isikhathi sokuthunyelwe: Mashi-29-2024