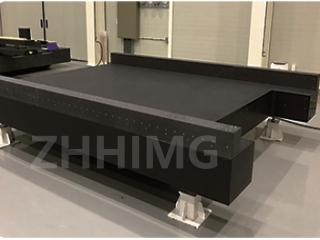

Izisekelo ze-granite zivame ukusetshenziswa emishinini ye-semiconductor ngenxa yokuqina kwazo okuhle kakhulu, ukuqina, kanye nezakhiwo zokudambisa. Lezi zisekelo zidlala indima ebalulekile ekugcineni ukunemba nokunemba kwemishini, okugcina kunegalelo ekhwalithini yemikhiqizo ye-semiconductor. Ngakho-ke, kubalulekile ukuqinisekisa ukuthi lezi zisekelo zigcinwa kahle futhi zihlangabezana nezidingo ezidingekayo.

Okulandelayo ezinye zezidingo zokugcinwa nokugcinwa kwezisekelo ze-granite emishinini ye-semiconductor:

1. Ukuhlanza Okuvamile: Izisekelo zegranite kufanele zihlanzwe njalo ukuze kuvinjelwe ukunqwabelana kothuli, imfucumfucu, nezinye izinto ezingcolisayo. Lezi zinto zingathinta ukunemba kwemishini futhi zibangele umonakalo ebusweni begranite. Ukuhlanza kufanele kwenziwe kusetshenziswa ibhulashi elithambile noma indwangu ye-microfiber kanye nesisombululo sensipho esithambile. Amakhemikhali anamandla noma izihlanzi ezihudulayo kufanele zigwenywe, njengoba zingabangela umonakalo ebusweni begranite.

2. Ukugcotshwa: Izisekelo ze-granite zidinga ukugcotshwa okufanele ukuze kuvinjelwe ukuguguleka nokuqinisekisa ukunyakaza okubushelelezi kwemishini. Kufanele kusetshenziswe i-lubricant efanele, njenge-lubricant esezingeni eliphezulu esekelwe ku-silicone. I-lubricant kufanele isetshenziswe ngamanani amancane futhi isatshalaliswe ngokulinganayo phezu komhlaba. I-lubricant eyengeziwe kufanele isulwe ukuze kuvinjelwe ukwakheka.

3. Ukulawulwa Kwezinga Lokushisa: Izisekelo ze-granite ziyazwela ezinguqukweni zokushisa, okungabangela ukwanda noma ukufinyela kokushisa. Imishini kufanele igcinwe endaweni elawulwa izinga lokushisa, futhi noma yiziphi izinguquko zokushisa kufanele zibe kancane kancane. Izinguquko ezingazelelwe zokushisa zingabangela ukucindezeleka ebusweni be-granite, okuholela ekuqhekekeni noma komunye umonakalo.

4. Ukulinganisa: Isisekelo se-granite kumele silinganiswe ukuqinisekisa ukusatshalaliswa ngokulinganayo kwesisindo phezu kobuso. Ukusatshalaliswa kwesisindo okungalingani kungabangela ukucindezeleka ebusweni, okuholela ekulimaleni ngokuhamba kwesikhathi. Kufanele kusetshenziswe inkomba yesilinganiso ukuhlola izinga lesisekelo njalo bese ulilungisa njengoba kudingeka.

5. Ukuhlolwa: Ukuhlolwa njalo kwesisekelo se-granite kubalulekile ukuze kutholakale noma yiziphi izimpawu zokuguguleka, umonakalo, noma amaphutha. Noma yiziphi izimpawu ezingavamile noma ezingavamile kufanele zilungiswe ngokushesha ukuze kuvinjelwe umonakalo owengeziwe noma ukungasebenzi kahle kwemishini.

Ekuphetheni, ukugcina nokugcina izisekelo ze-granite emishinini ye-semiconductor kubalulekile ukuqinisekisa ukunemba, ukunemba, kanye nekhwalithi yemishini nemikhiqizo. Ukuhlanza njalo, ukuthambisa, ukulawula izinga lokushisa, ukulinganisa, kanye nokuhlola kungenye yezidingo ezibalulekile okudingeka zilandelwe ukuze kugcinwe izisekelo ze-granite zisesimweni esihle. Ngokunamathela kulezi zidingo, izinkampani ze-semiconductor zingaqinisekisa ukuthi imishini nemikhiqizo yazo ihlala isikhathi eside futhi ithembekile, ekugcineni ibe negalelo empumelelweni nasekukhuleni kwazo embonini.

Isikhathi sokuthunyelwe: Mashi-25-2024