Izingxenye zegranite sezithandwa kakhulu embonini ye-semiconductor njengoba zinikeza izinzuzo eziningi kunezinto zendabuko. Igranite iyinto efanelekile yemishini ye-semiconductor ngenxa yezakhiwo zayo eziyingqayizivele zomzimba nezamakhemikhali. Kulesi sihloko, sizobheka ngokuningiliziwe umqondo wokuklama izingxenye zegranite nokuthi zisetshenziswa kanjani embonini ye-semiconductor.

I-Granite iyidwala elivela ngokwemvelo elakhiwe ngokuyinhloko yi-quartz, i-feldspar, ne-mica. Yaziwa ngokuminyana kwayo okuphezulu, ukumelana okuhle nokushisa, kanye nokuqina kwayo okuphezulu. Lezi zakhiwo ziyenza ibe yi-candidate efanelekile yemishini ye-semiconductor. Ngokungafani nezinsimbi, ine-coefficient encane yokwanda kokushisa, okusho ukuthi ubukhulu bayo buhlala bufana ngisho nokushintsha kwezinga lokushisa. Lokhu kuyenza ibe yi-candidate efanelekile yemishini enembile lapho ukubekezelelana okuqinile kubalulekile khona.

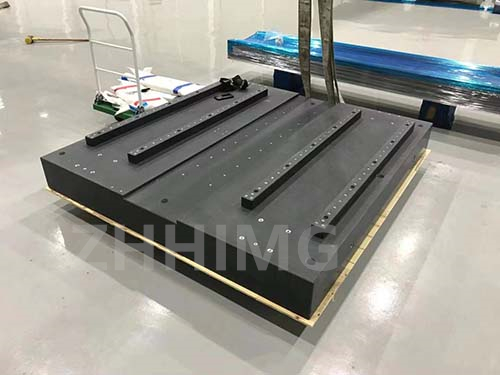

Enye yezinzuzo ezibalulekile zezingxenye zegranite ukuqina kwayo okuphezulu, okuthuthukisa ukunemba kwemishini. Izingxenye zegranite zikhethwa kakhulu ngemishini yokunemba njengezinsimbi ze-metrology kanye nemishini yokuhlola ubuso. Ukuqina kwayo kunciphisa ukudlidliza, ngaleyo ndlela, kunikeza ukunemba okungcono, ukuphindaphindwa, kanye nokunemba ekulinganisweni. Igranite yenze imishini yakwazi ukufeza izinga eliphakeme lokunemba ekulinganisweni, ngaleyo ndlela ithuthukisa ikhwalithi yezingxenye ze-semiconductor ezikhiqizwayo.

Ukuqina kokushisa kwe-Granite kwenza kube yinto efanelekile yemishini evezwe emazingeni okushisa aphezulu. Nakuba izingxenye eziningi ze-semiconductor zikhiqiza ukushisa, zidinga amazinga okushisa aphansi ukuze zisebenze kahle. Izingxenye ze-granite zingamelana nokushintshashintsha kokushisa ngaphandle kokushintsha isimo noma ukuphazamisa ukunemba kwemishini. Ngenxa yalokho, imishini ekhiqizwa kusetshenziswa izingxenye ze-granite iyahambisana futhi ithembekile.

Izingxenye ze-granite nazo ziyamelana nokugqwala, okuyinto ebalulekile embonini ye-semiconductor. Noma yikuphi ukugqwala kwemishini ye-semiconductor kungaholela ekungcoleni kwezingxenye ze-semiconductor ezikhiqizwayo. Lokhu kungcola kungaholela ekuncipheni kwekhwalithi, ukwehla kwesivuno, kanye nokungasebenzi kahle kwemishini kuma-semiconductor. Izingxenye ze-granite zivimbela ukugqwala futhi zigcina ubumsulwa bemishini ye-semiconductor ukuze isebenze isikhathi eside futhi ithembeke.

Izingxenye ze-granite nazo zinokumelana nokuguguleka okuphezulu, okusho ukuthi imishini ekhiqizwa ngayo ingahlala isikhathi eside futhi isebenze kangcono, ngisho nangaphansi kwezimo ezimbi kakhulu. Njengoba ihlala isikhathi eside, iqinisekisa ukusebenza kahle kwemishini ye-semiconductor, ngaleyo ndlela ithuthukise umkhiqizo futhi inciphise izindleko zizonke.

Ekuphetheni, imboni ye-semiconductor ikhula ngokushesha futhi iyashintsha, futhi ukusetshenziswa kwezingxenye ze-granite kuthole isidingo semakethe. Izakhiwo zayo ezihlukile zenze kwaba yinto efanelekile kubakhiqizi be-semiconductor ukukhiqiza imishini esebenza kahle kakhulu. Ukusetshenziswa kwezingxenye ze-granite kuthuthukise ikhwalithi yokukhiqiza imishini ye-semiconductor kanye nokusebenza okuthuthukisiwe, ukuqina, kanye nokunemba. Ngaphezu kwalokho, imboni ye-semiconductor izuze ekusetshenzisweni okukhulu kwezingxenye ze-granite ngezindleko zokulungisa ezincishisiwe, umkhiqizo othuthukisiwe, kanye nesikhathi sokuhola esincishisiwe. Ngakho-ke, kuyisinyathelo esihle kakhulu kubakhiqizi be-semiconductor ukwamukela izingxenye ze-granite njengento entsha nephumelelayo yokukhetha imishini yabo.

Isikhathi sokuthunyelwe: Mashi-20-2024