Umshini Wokulinganisa Ohlanganisiwe (i-CMM) uyithuluzi elibalulekile embonini yokukhiqiza, ikakhulukazi ekuqinisekiseni ukunemba nokunemba ngesikhathi senqubo yokukhiqiza. Nakuba i-CMM ingasetshenziswa ekulinganiseni izingxenye ezahlukene ezintweni ezahlukene, izingxenye ze-granite zinezici ezihlukile ezizihlukanisayo futhi zizenze zibe ezibalulekile enkambisweni yokukhiqiza.

I-granite iyitshe lemvelo elisetshenziswe amakhulu eminyaka ezindleleni ezahlukene, kusukela ekwakhiweni kwezakhiwo nasekwakheni kuya ezikhumbuzo nasebucikoni. Ngenxa yokuqina kwayo, ubulukhuni, kanye nokumelana nokuguguleka nokugqwala, i-granite nayo iyinto efanelekile yokukhiqiza izingxenye ezimbonini eziningi, kufaka phakathi izindiza, izimoto, kanye nezokwelapha.

Enye yezinzuzo ezibalulekile zokusebenzisa izingxenye ze-granite ekukhiqizeni ukuzinza kwazo okumangalisayo. I-Granite ine-coefficient ephansi yokwanda kokushisa, okusho ukuthi ubukhulu bayo nesimo sayo azishintshi ngisho noma zingaphansi kokushintshashintsha kwezinga lokushisa. Lokhu kuzinza kwenza i-granite ibe yinto enhle kakhulu yezinsimbi zokunemba namathuluzi omshini adinga ukunemba okuqhubekayo phezu kobubanzi obukhulu bamazinga okushisa.

Esinye isici esiyingqayizivele sezingxenye ze-granite ukuzinza kwazo okuphezulu. Ngokungafani nezinye izinto ezingase zande noma zigobe ngokuhamba kwesikhathi, i-granite igcina isimo sayo nosayizi wayo, iqinisekisa ukusebenza okuhlala njalo nokuthembekile. Ngakho-ke, izingxenye ze-granite zilungele ukusetshenziswa ezinhlelweni ezinembile kakhulu njengezinhlelo ze-optical neze-laser, lapho ngisho nokuphambuka okuncane noma ukuphambuka kungabangela amaphutha amakhulu.

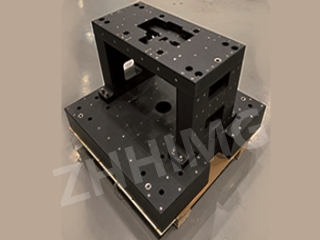

Inqubo yokukhiqiza izingxenye ze-granite idinga imishini ekhethekile kanye nobuchwepheshe. I-CMM idlala indima ebalulekile kule nqubo, iqinisekisa ukuthi izingxenye eziqediwe ziyahlangabezana nemigomo kanye nokubekezelelana okudingekayo. Ngokusebenzisa i-CMM, abakhiqizi bangalinganisa futhi baqinisekise ngokunembile ubukhulu bezingxenye ze-granite ezigabeni ezahlukene zokukhiqiza, kusukela ezintweni zokusetshenziswa kuya ekuhlolweni kokugcina.

Ngaphezu kwalokho, izingxenye ze-granite zimelana kakhulu nokuguguleka, ukuklwebheka, nokugqwala, okwenza zibe zilungele ukusetshenziswa ezindaweni ezinzima nezidinga kakhulu. Isibonelo, izingxenye ze-granite zivame ukusetshenziswa embonini yezimoto ukuhlanganisa izinjini, ama-transmission, nezinye izingxenye ezibalulekile ezidinga amandla aphezulu nokuqina.

Ekuphetheni, ukusetshenziswa kwezingxenye ze-granite ekukhiqizeni kuya ngokuya kuthandwa ngenxa yezakhiwo zazo ezihlukile kanye nezinzuzo. I-CMM iyithuluzi elibalulekile lokuqinisekisa ukunemba nokunemba kwezingxenye ze-granite, okubaluleke kakhulu ezimbonini eziningi. Njengoba isidingo esikhulayo sezingxenye ezisebenza kahle kakhulu sikhula, i-granite ngokuqinisekile izohlala iyinto eyigugu futhi ebalulekile emhlabeni wokukhiqiza.

Isikhathi sokuthunyelwe: Ephreli-02-2024