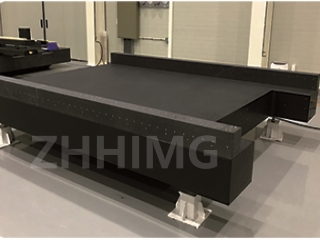

Amapulatifomu anemba we-granite, anokuqina kwawo okuphezulu, i-coefficient enwebekayo ephansi, ukusebenza kahle kokumanzisa kanye nezindawo zemvelo ezilwa nozibuthe, anenani lesicelo elingenakushintshwa ekukhiqizeni okuphezulu nezinkambu zocwaningo lwesayensi lapho ukunemba nokuzinza kudingwa khona kakhulu. Okulandelayo yizimo zayo eziyisisekelo zohlelo lokusebenza kanye nezinzuzo zobuchwepheshe:

I. Inkambu yemishini yokucubungula enembe kakhulu

Imishini yokukhiqiza iSemiconductor

Izimo zohlelo lokusebenza: Ithebula lomshini wokwenza umshini we-lithography, isisekelo somshini wokudayela esilucwecwana, iplatifomu yokubeka impahla yokupakisha.

Inani lobuchwepheshe:

I-coefficient yokunwetshwa okushisayo kwe-granite kuphela (0.5-1.0) ×10⁻⁶/℃, engamelana nokuguquguquka kwezinga lokushisa ngesikhathi sokuchayeka kwe-nanoscale yomshini we-lithography (iphutha lokususwa <0.1nm endaweni engu-±0.1℃).

Isakhiwo sangaphakathi se-micro-pore sakha i-damping yemvelo (i-damping ratio 0.05 kuya ku-0.1), icindezela ukudlidliza (amplitude <2μm) ngesikhathi sokusika ngesivinini esikhulu ngomshini wokudayela futhi iqinisekise ukuthi unqenqema lwama-Ra we-wafer cutting lungaphansi kwe-1μm.

2. Imishini Yokugaya Ngokunemba kanye Nemishini Yokukala (CMM)

Icala lesicelo:

Isisekelo somshini wokulinganisa wezixhumanisi ezintathu sisebenzisa ukwakheka kwegwadle okubalulekile, nokucaba okungu-±0.5μm/m. Ihlanganiswe nomzila wesitimela esintantayo emoyeni, ifinyelela ukunemba kokunyakaza kwezinga le-nano (phinda ukunemba kokumisa okungu-±0.1μm).

I-worktable yomshini wokugaya optical ithatha isakhiwo esiyinhlanganisela se-granite nensimbi yesiliva. Lapho ugaya ingilazi ye-K9, ukuphaphama kwendawo kungaphansi kuka-λ/20 (λ=632.8nm), kuhlangabezana nezidingo zokucubungula ezibushelelezi zamalensi e-laser.

Ii. Inkambu ye-Optics ne-Photonics

Izibonakude zezinkanyezi kanye nezinhlelo ze-laser

Izinhlelo zokusebenza ezijwayelekile:

Inkundla yokusekela yendawo ekhanyayo yesibonakude esikhulu somsakazo ithatha isakhiwo sekhekheba lezinyosi, esilula kusisindo somuntu siqu (ukuminyana okungu-2.7g/cm³) futhi sinokumelana nokudlidliza komoya okuqinile (ukuguqulwa okungu-< 50μm ngaphansi komoya weleveli engu-10).

I-platform ye-optical ye-laser interferometer isebenzisa i-granite encane ye-micro-porous. Isibonisi silungiswa nge-vacuum adsorption, ngephutha lokucaba okungaphansi kuka-5nm, okuqinisekisa ukuzinza kokuhlolwa kokubona okunembe kakhulu okufana nokutholwa kwamagagasi adonsela phansi.

2. Ukunemba kwengxenye ye-optical processing

Izinzuzo zobuchwepheshe:

Ukungena kukazibuthe kanye nokusebenza kukagesi kweplathifomu yegwadle kusondele kuqanda, kugwema umthelela wokuphazamiseka kazibuthe kagesi ezinqubweni ezinembayo ezifana nokupholisha kwe-ion beam (IBF) kanye nokupholisha kwe-magnetorheological (MRF). Inani lokunemba komumo we-PV welensi ye-asphical ecutshunguliwe ingafinyelela ku-λ/100.

Iii. Ukuhlolwa kwe-Aerospace kanye Nokunemba

Inkundla yokuhlola ingxenye yendiza

Izimo zohlelo lokusebenza: Ukuhlolwa kwezinhlangothi ezintathu kwamablade endiza, ukukalwa komumo nokubekezelela isikhundla sezingxenye zesakhiwo se-aviation aluminium alloy.

Ukusebenza okubalulekile:

Ingaphezulu leplathifomu yegwadle iphathwa ngokugqwala kwe-electrolytic ukuze kwakheke amaphethini amahle (ngokumahhadla kwe-Ra 0.4-0.8μm), afanele ama-trigger probes anembe kakhulu, futhi iphutha lokuthola iphrofayela ye-blade lingaphansi kuka-5μm.

Ingakwazi ukumelana nomthwalo ongaphezu kuka-200kg wezingxenye zezindiza, futhi ukuguquka kwesicaba ngemva kokusetshenziswa isikhathi eside kungaphansi kuka-2μm/m, okuhlangabezana nezidingo zokugcinwa okunembayo zeBanga le-10 embonini ye-aerospace.

2. Ukulinganisa izingxenye ze-inertial navigation

Izidingo zobuchwepheshe: Ukulinganisa okuqinile kwamadivayisi angasebenzi njengama-gyroscopes nama-accelerometers kudinga inkundla yesithenjwa ezinzile.

Isixazululo: Iplathifomu yegwadle ihlanganiswe nesistimu yokuhlukanisa ukudlidliza esebenzayo (imvamisa yemvelo engu-< 1Hz), ifinyelela ukulinganiswa okuphezulu kokunemba kokuzinza kwe-zero-offset yezingxenye ze-inertial <0.01°/h endaweni enesivinini sokudlidliza <1×10⁻⁴g.

Iv. I-Nanotechnology kanye ne-Biomedicine

Inkundla ye-scan probe microscope (SPM)

Umsebenzi oyinhloko: Njengesisekelo se-atomic force microscopy (AFM) kanye ne-scan tunneling microscopy (STM), idinga ukuhlukaniswa nokudlidliza kwemvelo kanye nokukhukhuleka okushisayo.

Izinkomba zokusebenza:

Iplathifomu yegwadle, ihlanganiswe nemilenze yokuhlukanisa ukudlidliza kwe-pneumatic, inganciphisa izinga lokudlulisela lokudlidliza kwangaphandle (1-100Hz) libe ngaphansi kuka-5%, ifinyelele ukuthwebula kwe-athomu ye-AFM endaweni yomoya (ukulungiswa <0.1nm).

Ukuzwela kwezinga lokushisa kungaphansi kuka-0.05μm/℃, ehlangabezana nezimfuneko zokubhekwa kwe-nanoscale kwamasampula ebhayoloji endaweni yokushisa engashintshi (37℃±0.1℃).

2. Imishini yokupakisha ye-Biochip

Ikesi lesicelo: Iplathifomu yokuqondanisa enemba okuphezulu yama-chips okulandelanisa kwe-DNA yamukela ama-rail angumhlahlandlela antantayo emoyeni, ngokunemba kokuma okungu-±0.5μm, iqinisekisa ukubopha kwe-micron encane phakathi kwesiteshi se-microfluidic kanye ne-electrode etholwayo.

V. Izimo Zokusebenza Ezisafufusa

Isisekelo semishini yekhompyutha ye-Quantum

Izinselele zobuchwepheshe: Ukukhohlisa i-Qubit kudinga amazinga okushisa aphansi kakhulu (izinga le-mK) kanye nemvelo yomshini ozinzile kakhulu.

Isixazululo: Indawo yokunweba ephansi kakhulu eshisayo yegwadle (izinga lokunweba <1ppm ukusuka ku-200℃ ukuya kuzinga lokushisa legumbi) lingahambisana nezici zokufinyela zamamagnethi we-ultra-low lokushisa ama-superconducting, iqinisekise ukunemba kokuqondanisa ngesikhathi sokupakishwa kwama-chips we-quantum.

2. Uhlelo lwe-Electron Beam Lithography (EBL).

Ukusebenza okubalulekile: Indawo yokwahlukanisa yeplathifomu yegwadle (ukumelana > 10¹³Ω · m) ivimbela ukusakazeka kwe-electron beam. Ihlanganiswe ne-electrostatic spindle drive, ifinyelela ukubhalwa kwephethini ye-lithography enembayo enobubanzi bomugqa we-nanoscale (< 10nm).

Isifinyezo

Ukusetshenziswa kwamapulatifomu anemba egwadule kunwetshiwe kusukela emishinini enembayo evamile kuya ezinkambini ezisezingeni eliphezulu njenge-nanotechnology, i-quantum physics, ne-biomedicine. Ukuncintisana kwawo okuyinhloko kusekuhlanganisweni okujulile kwezakhiwo zempahla kanye nezidingo zobunjiniyela. Ngokuzayo, ngokuhlanganiswa kobuchwepheshe bokuqinisa okuyinhlanganisela (okufana ne-graphene-granite nanocomposites) kanye nobuchwepheshe benzwa obuhlakaniphile, izinkundla zegwadle zizongena eziqondisweni zokunemba kwezinga le-athomu, ukuqina kobubanzi bezinga lokushisa eligcwele, kanye nokuhlanganiswa kwezakhi eziyisisekelo zemisebenzi eminingi, okusekela ukuhlanganiswa kwezakhi eziyisisekelo ezilandelayo.

Isikhathi sokuthumela: May-28-2025