Ezindaweni eziqondile zokukhiqiza ngokunemba okuphezulu—kusukela ezimotweni nasezindizeni kuya kuma-elekthronikhi athuthukile—umkhawulo wephutha awukho. Ngenkathi ama-Granite Surface Plates esebenza njengesisekelo esijwayelekile se-metrology ejwayelekile, i-Granite Inspection Plate iyi-benchmark ekhethekile, eqinile kakhulu enikezelwe ekuqinisekisweni kwezingxenye kanye nokuhlanganiswa okusizwayo. Iyithuluzi elibalulekile elisetshenziselwa ukuqinisekisa i-geometry yangaphandle, ukuphambuka kobukhulu, kanye nokuba bushelelezi kwezingxenye ezinenani eliphezulu, ukuqinisekisa ukuthi ziyahlangabezana nezidingo eziqinile zobunjiniyela besimanje.

Isimiso se-Ultra-Stable Datum

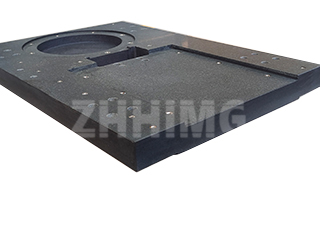

Umsebenzi oyinhloko we-Granite Inspection Plate usekelwe ekuzinzeni kwayo okuphezulu kanye nomgomo "wobuso be-datum obuzinzile kakhulu."

Indawo yokusebenza ifakwa enqubweni yokugoqa enembile kakhulu, okufeza ukugoba kobuso okuphansi kakhulu (ngokuvamile i-Ra ≤ 0.025 μm) kanye nokunemba kokusicaba kuze kufike ku-Grade 0 (≤ 3 μm/1000 mm). Lokhu kunikeza indiza yokubhekisela engaguquki, engaguquki.

Ngesikhathi sokuhlola, izingxenye zibekwa kulo mhlaba. Amathuluzi anjengezinkomba zokudayela noma ama-lever gauges abe esesetshenziswa ukukala igebe lemizuzu phakathi kwengxenye nepuleti. Le nqubo ivumela onjiniyela ukuthi baqinisekise ngokushesha ukuthi i-flat kanye ne-parallelism yengxenye, noma basebenzise ipuleti njengedatha eqinile ukuhlola amapharamitha abalulekile njengesikhala semigodi kanye nokuphakama kwesinyathelo. Okubaluleke kakhulu, ukuqina okuphezulu kwe-granite (i-Elastic Modulus ye-80-90 GPa) kuqinisekisa ukuthi ipuleti ngokwayo ayiphambuki noma ayiguquki ngaphansi kwesisindo sezingxenye ezisindayo, okuqinisekisa ubuqotho bedatha yokuhlola.

Ubunjiniyela Bokuhlola: Ukuklama Nokuphakama Kwezinto Ezibonakalayo

Amapuleti Okuhlola e-ZHHIMG® aklanywe ngokugxila ekuzivumelaniseni nokuhlolwa kanye nemininingwane eningiliziwe:

- Ukuzivumelanisa Nezimo Ngokwezifiso: Ngale kwendawo eyisicaba eyinhloko, amamodeli amaningi afaka imigodi ehlanganisiwe noma imigoqo engu-V. Lokhu kubalulekile ekulungiseni ngokuphephile izingxenye eziyinkimbinkimbi noma ezingalingani, njengemigoqo kanye nezingxenye ezimise okwediski, ukuvimbela ukunyakaza ngesikhathi sokulinganisa okubucayi.

- Ukuphepha Nokusetshenziswa: Imiphetho iqedwa nge-chamfer ethambile, eyindilinga ukuze kuthuthukiswe ukuphepha komqhubi futhi kuvinjelwe ukulimala ngengozi.

- Uhlelo Lokulinganisa: Isisekelo sepuleti sifakwe izinyawo zokusekela ezilungisekayo (njengezikulufo zokulinganisa), okuvumela umsebenzisi ukuthi alungise ipuleti ngokunembile ukuze liqondaniswe kahle ngokuvundlile (≤0.02mm/m ngokunemba).

- Ikhwalithi Yezinto Ezisetshenziswayo: Sisebenzisa i-granite yezinga eliphezulu kuphela, engenamabala nemifantu, edlula enkambisweni yokuguga yemvelo yeminyaka emi-2 kuya kwemi-3. Le nqubo ende isusa ukucindezeleka kwezinto zangaphakathi, iqinisekisa ukuzinza kwesikhathi eside kanye nesikhathi sokugcinwa kokunemba esingaphezu kweminyaka emihlanu.

Lapho Ukunemba Kungaxoxiswana Khona: Izindawo Ezibalulekile Zokusebenza

Ipuleti Lokuhlola I-Granite libaluleke kakhulu lapho ukunemba okuphezulu kuthinta ngqo ukuphepha nokusebenza:

- Imboni Yezimoto: Kubalulekile ukuqinisekisa ukuthi amabhlogo enjini kanye nama-gearbox aqinile ukuze kuqinisekiswe ukuqina kokuvala.

- Umkhakha Wezindiza: Isetshenziselwa ukuqinisekiswa okubucayi kwezinsika ze-turbine kanye nezingxenye zegiya lokufika, lapho ukuphambuka kusongela ukuphepha kwendiza.

- Ukwenza Isikhunta Nokufa: Ukuqinisekisa ukunemba kobuso bemigoqo yesikhunta kanye nama-core, ukuthuthukisa ngqo ikhwalithi ye-cast yokugcina noma umkhiqizo owenziwe.

- I-Electronics & Semiconductor: Kubalulekile ekuhlolweni kokuhlanganiswa kwezingxenye zemishini ye-semiconductor esezingeni eliphezulu, lapho ukuvumelanisa kwezinga le-micron kuyadingeka ukuze kube nokunemba kokusebenza.

Ukuvikela Idatha Yakho: Izindlela Ezinhle Zokulungisa

Ukuze kulondolozwe ukunemba kwe-sub-micron ye-Inspection Plate yakho, kudingeke ukunamathela ezimisweni zokulungisa eziqinile:

- Ukuhlanzeka Kuyimpoqo: Ngokushesha ngemva kokuhlola, susa zonke izinsalela zezingxenye (ikakhulukazi ama-chips ensimbi) ebusweni usebenzisa ibhulashi elithambile.

- Isexwayiso Sokugqwala: Vimbela ngokuqinile ukubeka uketshezi olugqwalisayo (ama-asidi noma ama-alkali) ebusweni be-granite, njengoba lungaqopha itshe unomphela.

- Ukuqinisekiswa Okuvamile: Ukunemba kwepuleti kumele kuqinisekiswe njalo. Sincoma ukulinganiswa ngama-gauge aqinisekisiwe okuthi flatness gauges njalo ezinyangeni eziyisithupha.

- Ukuphatha: Uma uhambisa ipuleti, sebenzisa amathuluzi okuphakamisa akhethekile kuphela futhi ugweme ukutshekisa noma ukufaka ipuleti ekushayweni okungazelelwe, okungalimaza ukuqina kwayo kwesikhathi eside.

Ngokuphatha i-Granite Inspection Plate njengethuluzi elinembile kakhulu, abakhiqizi bangaqinisekisa amashumi eminyaka okuqinisekiswa okunokwethenjelwa kobukhulu, okusekela ikhwalithi nokuphepha kwemikhiqizo yabo eyinkimbinkimbi kakhulu.

Isikhathi sokuthunyelwe: Novemba-05-2025