Kubakhiqizi kanye nochwepheshe be-metro kulo lonke elaseNyakatho Melika, kusukela ezizindeni zezimboni zase-United States kuya ezindinganisweni ezifunwayo zabahlinzeki be-granite surface plate Canada, i-granite surface plate iyisiqiniseko esiqondile sokulinganisa ubukhulu. Leli thuluzi eliyisisekelo, kungakhathaliseki ukuthi lisebenza njengendiza elula yokubhekisela noma elihlanganiswe njengengxenye ebalulekile emishinini ethuthukisiwe njenge-granite surface plate CNC bed, limelela ukutshalwa kwezimali okukhulu ekulawulweni kwekhwalithi. Noma kunjalo, ukuqinisekisa lokho kutshalwa kwezimali kudinga ukuqonda okujulile ngezindleko zako, izidingo zokulungisa, kanye nokuqinisekiswa kokulinganiswa okufanele.

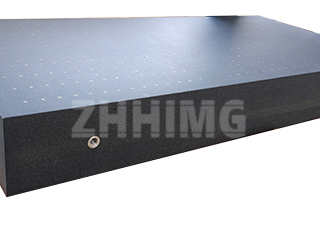

Umbuzo wokuqala othi, “Iyini izindleko zepuleti lobuso le-granite?”, uvula umnyango wesiphakamiso senani eliyinkimbinkimbi. Intengo yepuleti lobuso akuyona nje izindleko zezinto zokusetshenziswa; iwukubonakaliswa kwekhwalithi yetshe (ubuningi, ukugoba, kanye nokuzinza), ukunemba kwenqubo yokubopha, kanye nokuqina kwenqubo yokuqinisekisa. I-granite eshibhile, enobukhulu obuphansi, evame ukubonwa ngombala wayo okhanyayo, ingase yonge izindleko zepuleti lobuso le-granite elingaphambili, kodwa ngokungenakugwenywa iholela ezindlekweni eziphakeme zesikhathi eside ngenxa yokuguguleka okusheshayo, ukuthambekela okukhulu ekungazinzini kokushisa, kanye nokulinganiswa kabusha okuvamile. I-granite emnyama yekhwalithi ephezulu, njengezinto ezisetshenziswa yi-ZHHIMG® enobukhulu obuseduze no-3100 kg/m³, iqinisekisa ukuzinza okuphezulu kanye nokugcinwa okuncane njalo, okwenza kube ukukhetha okungabizi kakhulu phakathi nomjikelezo wokuphila komkhiqizo.

Lokhu kuphila isikhathi eside kuhlobene ngqo nemikhuba ebalulekile yokunakekelwa kwepuleti le-granite surface. Ipuleti le-granite, naphezu kokuqina kwalo okubonakalayo, lisengozini yezitha ezimbili eziyinhloko: ukuguguleka okubuhlungu kanye nokushaqeka kokushisa. Uhlelo lokunakekelwa kwepuleti le-granite surface oluphelele kumele lubhekane nakho kokubili ngendlela ephumelelayo.

Ingxenye ebalulekile yalolu hlelo ukuhlanza ipuleti lobuso begranite. Inqubo ecophelelayo yokuhlanza izindawo zobuso begranite ayikona nje ukususa ukungcola okubonakalayo; imayelana nokususa izinhlayiya ezincane kakhulu, ezihuzukayo—njengothuli lokugaya noma i-slurf yensimbi—lapho zivaleleke phakathi kwento yokusebenza negranite, zisebenze njengephepha lesihlabathi, zibhubhise ubucaba obuqinisekisiwe. Ungalokothi usebenzise izihlanzi eziqinile noma izihlanzi ezine-acidic, ezingashiya izinsalela noma ziqobe ubuso betshe. Esikhundleni salokho, isisombululo sokuhlanza ipuleti lobuso begranite esizinikele, esingena-pH, esihambisana nendwangu ekhethekile, engena-lint, kumele sisetshenziswe nsuku zonke ukuze kugcinwe isimo esihle sendawo yokubhekisela. Lesi sinyathelo esijwayelekile asinakuxoxiswana ngaso ukuze kulondolozwe ukunemba, ikakhulukazi kumapuleti asebenza ku-Grade 00 noma ukubekezelelana kwelabhorethri.

Kodwa-ke, ngisho nokuhlanza nokunakekela okuqinile kakhulu akukwazi ukuvimbela ngokuphelele imiphumela ehamba kancane, eqoqayo yokusetshenziswa kanye nezinguquko zemvelo. Lokhu kusiletha esidingweni sepuleti lobuso le-granite elilinganiswe ngempela. Igama elithi “elilinganisiwe” livame ukusetshenziswa kabi; kumele lisho ukuqinisekiswa okulandelekayo kokuthambeka kwepuleti iyonke, ukuthambeka kwendawo, kanye nokuphindeka. Izimboni ezinembayo ephezulu, kufaka phakathi lezo ezikhonzwa abahlinzeki bepuleti lobuso le-granite eCanada, zithembele ezitifiketini zokulinganisa ezilandelekayo ezikhishwe amalabhorethri agunyaziwe asebenzisa i-laser interferometry kanye namazinga kagesi.

Ukuzibophezela kwe-ZHHIMG® ekuqondeni kuqinisekisa ukuthi ipuleti ngalinye eliphuma endaweni yalo elawulwa yisimo sezulu engamamitha ayi-10,000—isakhiwo esakhiwe ngokhonkolo oluvidliza kanye nemisele yokuhlukanisa ukuzamazama komhlaba—siqinisekiswe ngokucophelela. Lokhu kuzinikela kubaluleke kakhulu lapho ipuleti lisetshenziswa njengesisekelo sepuleti le-granite surface plate CNC. Kulesi sicelo, ipuleti lisebenza njengesisekelo sesakhiwo seziqondisi eziqondile zomshini kanye nama-motor. Noma yiliphi iphutha lejiyometri ku-granite lihunyushwa ngokushesha libe amaphutha ekulawuleni ukunyakaza kwe-CNC, okuthinta ngqo ukunemba kokugcina kwengxenye emshinini. Ngenxa yalokho, isikhathi sokulinganisa sesicelo se-CNC sepuleti le-granite surface plate kufanele sibe sivame kakhulu futhi siqine kunaleso sepuleti lokuhlola elijwayelekile.

Ngale kokuba yisicaba kanye nekhwalithi yezinto ezibonakalayo, abasebenzisi kumele bacabangele nomklamo wesakhiwo. Ubunjiniyela obufanele bepuleti lobuso bebhulokhi le-granite—kufaka phakathi ukwakheka nokubekwa kwezinto zokuphakamisa, amaphuzu okusekela, kanye nesilinganiso sobukhulu nobubanzi—kubalulekile ukuvimbela ukuphambuka ngaphansi komthwalo. Lokhu kuqina kwesakhiwo kuyisici esiyinhloko esiqhuba izindleko zepuleti lobuso be-granite langempela futhi kuwuphawu lwabakhiqizi bezinga lomhlaba abaqondayo ukuthi ukunemba kwakhiwa kusukela phansi kuya phezulu.

Ngokubeka phambili ubuningi bezinto ezibonakalayo obuphezulu, ukusebenzisa ukunakekelwa kwepuleti lobuso le-granite okuhlelekile kanye nokuhlanza uhlelo lwepuleti lobuso le-granite, kanye nokuzibophezela ezinsizeni zepuleti lobuso le-granite ezilandelekayo nezijwayelekile, abasebenzisi baqinisekisa ukuthi isisekelo sabo se-metrology sihlala siyindawo yokubhekisela engaguquki, siletha ukunemba okuqhubekayo, kwezinga le-nanometer kungakhathaliseki ukuthi bawatholaphi amapuleti abo—kungaba kumthengisi wendawo noma umholi wamazwe omhlaba ofana ne-ZHHIMG®.

Isikhathi sokuthunyelwe: Novemba-25-2025