Ezweni elisheshayo lokukhiqizwa kwezinto zikagesi, lapho ukwenziwa kube lula kwamadivayisi kuqhuba ukusungula izinto ezintsha okungapheli, ubuchwepheshe be-Surface-mount (SMT) buhlala buyinqubo ebalulekile yokubeka izingxenye kumabhodi wesekethe aphrintiwe (ama-PCB). Imishini yesimanje ye-SMT—imishini yokukhetha nokubeka, amaphrinta esikrini, kanye nezinhlelo zokuhlola okuzenzakalelayo kwe-optical (AOI)—kumele zisebenze ngesivinini namazinga okunemba ahambisana nokungenakwenzeka. Ukuqina nobuqotho besisekelo somshini akuzona nje izinto ezisekelayo; ziyisithiyo esikhulu ekuphumeni nasekukhiqizeni. Ezinhlelweni eziningi zokusebenza okuphezulu, ikhambi eliqinile nelingaguquki lisekusetshenzisweni kwesisekelo somshini we-granite esikhethekile sobuchwepheshe be-Surface-mount.

Njengoba ubukhulu bezingxenye buqhubeka nokuncipha (kuze kufike ku-01005 nangaphezulu), futhi isivinini sokubekwa sikhuphuka, ukuzinza okuguquguqukayo kwesistimu kumele kuhlolwe kabusha. Yingakho abakhiqizi bemishini abahamba phambili bephendukela ezimpahleni zangaphakathi zamatshe emvelo ukuze bakhe isisekelo somshini we-granite wobuchwepheshe be-Surface-mount.

Okubalulekile Kwesisekelo Se-Granite ku-High-Speed SMT

Kungani into yasendulo, yemvelo iyisinqumo esifanele sokwenza izinto ze-SMT ezisebenza kahle kakhulu? Impendulo isekelwe ku-physics eyisisekelo yokunyakaza okunembile. Imishini ye-SMT esheshayo ikhiqiza amandla ashukumisayo abalulekile. Ukusheshisa okusheshayo kanye nokwehla kwejubane kwezinhlelo ze-gantry, amakhanda, kanye nama-conveyor kudala ukudlidliza, uma kungalawulwa, okungasakazeka kulo lonke isakhiwo somshini. Lokhu kunyakaza kuhumusha ngokuqondile ukungalungi kokubekwa, amaphutha okunamathela, kanye nokwethembeka kokuhlolwa okunciphile.

Isixazululo umbhede womshini we-granite wobuchwepheshe bokufaka i-Surface. Izakhiwo ze-Granite zenza kube yinto engcono kakhulu yokumunca nokunciphisa lezi ziphazamiso zangaphakathi nezangaphandle:

-

Izici Eziphezulu Zokudambisa: Uma kuqhathaniswa nensimbi noma i-aluminium, i-granite ine-coefficient ephezulu kakhulu yokudambisa kwangaphakathi. Lokhu kusho ukuthi ukudlidliza komshini okubangelwa ukunyakaza kwesivinini esikhulu kunyamalala ngokushesha njengokushisa okuncane, okukuvimbela ekuphazamiseni ikhanda lokubeka noma i-optics yokuhlola. Lesi sikhathi sokuphumula esisheshayo sibalulekile ekukhuliseni umthamo ngaphandle kokulahlekelwa ukunemba.

-

I-Thermal Inertia kanye ne-Low CTE: Indawo ye-SMT, ikakhulukazi eduze kwama-oven aphinde ageleze noma ngaphakathi kwendawo yokusebenza eseduze, ingaba nokushintshashintsha okuncane kokushisa. Izinsimbi zisabela kakhulu kulezi zinguquko, okuholela ekwandeni kokushisa kanye nokukhukhuleka kobukhulu. Kodwa-ke, i-coefficient ephansi yokwandiswa kokushisa (CTE) yombhede we-granite wobuchwepheshe bokufaka i-Surface iqinisekisa ukuthi i-geometry yokuqondanisa okubalulekile komshini ihlala izinzile phakathi nobubanzi bokushisa bokusebenza. Lokhu kuzinza kokushisa kubalulekile ekugcineni ubuqotho bokuqondanisa, ikakhulukazi phezu kwezinyathelo ezinkulu zomshini.

-

Ukuthamba Okuphelele Kokunyakaza Okuqondile: I-Granite ingahlanganiswa futhi ipholishwe ukuze kufezwe ukubekezelelana kokuthamba okulinganiselwe kuma-micron angaphansi. Leli zinga eliphakeme lokunemba alikwazi ukuxoxiswana ngeziqondiso eziqondile zokufaka, ama-air bearings, kanye nezinhlelo zezimoto. Ukunemba okuphezulu kwesisekelo se-granite sobuchwepheshe bokufaka i-Surface kuqinisekisa ukunemba okuphelele kanye nokuhambisana kwama-axes ahamba ngokushesha, okuyisici esiqondile sokunemba kokubekwa kwengxenye.

Ubunjiniyela besizukulwane esilandelayo se-SMT: Izingxenye kanye nokuhlanganiswa

Indima ye-granite ku-SMT idlulela ngale kwesisekelo somshini omkhulu we-granite. Ipulatifomu eqinile ye-SMT ivame ukusebenzisa izingxenye ze-granite ezenziwe ngokwezifiso zobuchwepheshe bokufaka i-Surface ezihlanganiswe esakhiweni esiyinhloko. Lezi zingxenye zingafaka:

-

Amabhulokhi Okuthambeka Okunembile: Asetshenziswa ukuqinisekisa indawo eqinile yezinhlelo zokubona ezizwela kakhulu, izinzwa zokuqondanisa nge-laser, kanye namakhamera athembekile.

-

Izindawo Zokuthwala Umoya: Ukuze uthole amakhanda okukhetha nokubeka anembile kakhulu, i-granite inikeza indawo efanelekile, ecwebezelisiwe kakhulu, engenazo izimbobo esebenza kahle nama-air bearings, enikeza ukunyakaza okungenakuphikiswana, nokuphindaphindeka.

-

Amapuleti Amathuluzi Angokwezifiso: Izinto ezincane zegranite ezenzelwe ukubamba nokubhekisela kumathuluzi athile enqubo, okuqinisekisa ukulungiswa okuphindaphindwayo ngokuhamba kwesikhathi kanye nokushisa.

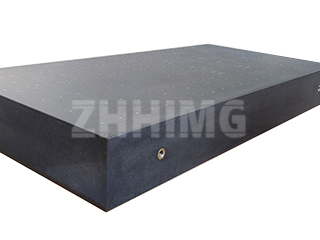

Inqubo yokukhiqiza isisekelo somshini we-granite osebenza kahle kakhulu wobuchwepheshe be-Surface-mount iwubufakazi bokuhlanganiswa kobuciko bendabuko kanye nobunjiniyela obuthuthukisiwe. Kuhilela ukukhetha i-granite emnyama yemvelo esezingeni eliphezulu, ukuyiqeda ukucindezeleka, bese uyilungisa usebenzisa imishini ye-CNC yesimanje. Izici ezifana nemigodi ethintekile, izikhala ze-T, imigodi ehlanganisiwe yokuqondisa ikhebula, kanye nezindawo zokubopha zezinsimbi zensimbi zihlanganiswe ngokucophelela nemininingwane eqondile yekhasimende.

Imbuyiselo Yokutshalwa Kwezimali: Ukunemba Nokuphila Isikhathi Eside

Ukutshala imali esisekelweni se-granite semishini ye-SMT kuyisinqumo esihlakaniphile esinikeza imbuyiselo ecacile ekutshalweni kwezimali. Ngenkathi izindleko zezinto zokuqala zingase zibe phezulu kunensimbi, izinzuzo zesikhathi eside maqondana nokukhiqiza okuphezulu, ukuncipha kwezinsalela, kanye nesikhathi esincane sokungasebenzi ngenxa yokungahambisani kahle kwesakhiwo kudlula kakhulu umehluko.

Umbhede wegranite wobuchwepheshe bokufaka i-Surface unikeza indiza yokubhekisela ethembekile nehlala njalo ezogcina ubuqotho bayo obunobukhulu amashumi eminyaka, imelana nokuguguleka, ukugqwala, kanye nezinguquko zesakhiwo sangaphakathi. Kubakhiqizi abasebenza emngceleni wesimanje wokuhlanganiswa kwe-elekthronikhi, lapho ukunemba kusho umehluko phakathi komkhiqizo ophumelelayo kanye nokukhiqiza okuhlulekile, ukuzinza okunikezwa yisisekelo somshini wegranite okhethekile wobuchwepheshe bokufaka i-Surface kuyisiqinisekiso esiphezulu sokusebenza nokuthembeka. Ukukhetha umshini onalesi sisekelo ukukhetha ukuhambisana, isivinini, kanye nekhwalithi engaguquki ekuhlanganisweni kwamadivayisi kagesi ayinkimbinkimbi kakhulu emhlabeni.

Isikhathi sokuthunyelwe: Disemba-01-2025