.

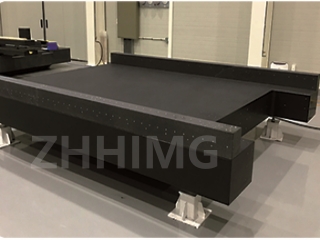

Ezimweni zokucubungula ngokunemba okuphezulu kwemishini yokumaka i-laser yezinga le-picosecond, isisekelo, njengengxenye eyinhloko esekela imishini, ukukhethwa kwezinto zayo kunquma ngqo ukuzinza kokunemba kokucubungula. I-Granite ne-cast iron kuyizinto ezimbili ezivamile zokukhiqiza isisekelo. Lesi sihloko sizoqhathanisa izici ezifana nezakhiwo zomzimba, isimiso sokunciphisa ukuchaneka, kanye nedatha yokusetshenziswa okusebenzayo, okuhlinzeka ngesisekelo sesayensi sokuthuthukisa imishini.

I. Umehluko Wezakhiwo Zezinto Ezibonakalayo: I-Logic Eyisisekelo Yokusebenza Okunembile

I-Granite iyidwala lemvelo eliyi-igneous, elakhiwe yi-crystallization eseduze yamaminerali afana ne-quartz ne-feldspar ngaphakathi. Ibonakala ngesakhiwo esiminyene kanye nobunzima obukhulu. Ubuningi bayo buvame ukuba phakathi kuka-2.7 no-3.1g/cm³, futhi i-coefficient yayo yokwanda kokushisa iphansi kakhulu, cishe (4-8) ×10⁻⁶/℃, engamelana ngempumelelo nethonya lokushintsha kwezinga lokushisa ekunembeni kwemishini. Ngaphezu kwalokho, isakhiwo esincane esiyingqayizivele se-granite siyinika ukusebenza okuhle kakhulu kokuncibilikisa, okwenza ikwazi ukumunca ngokushesha amandla okudlidliza angaphandle futhi inciphise ukuphazamiseka kokudlidliza ekunembeni kokucubungula.

Insimbi ephothiwe, njengezinto zendabuko zezimboni, inobuningi obungu-7.86g/cm³, amandla aphezulu okucindezela, kodwa iyashisa

Inombolo yokwanda (cishe i-12×10⁻⁶/℃) iphindwe ka-1.5-3 kune-granite. Ngaphezu kwalokho, kunezakhiwo ze-graphite eziqhekekile ngaphakathi kwensimbi ephonswe. Ngesikhathi sokusetshenziswa isikhathi eside, lezi zakhiwo zingaholela ekugxilweni kokucindezeleka, zithinte ukuzinza kwezinto futhi kamuva zibangele ukwehla kokunemba.

Ii. Indlela Yokunciphisa Ngokunembile Emishinini Yezinga Le-Picosecond

Ukucutshungulwa kwe-laser kwezinga le-Picosecond kunezidingo eziphakeme kakhulu zokuzinza kwemvelo. Noma yikuphi ukuguquka okuncane kwezinto eziyisisekelo kuzokhuliswa kumphumela wokucubungula. Ukushintshashintsha kwezinga lokushisa, ukudlidliza okubangelwa ukusebenza kwemishini, ukukhathala ngaphansi komthwalo wesikhathi eside, njll., konke kuyizinto ezibalulekile eziholela ekunciphiseni ukunemba.

Uma izinga lokushisa lishintsha, usayizi wegranite uyashintsha kancane ngenxa yokwanda kwayo okuphansi kokushisa. I-coefficient enkulu yokwanda kokushisa yensimbi ephonswe izokwenza ukuthi isisekelo siguqulwe okunzima ukuyibona ngeso lenyama. Lokhu kuguquguquka kuzothinta ngqo ukuzinza kwendlela ye-laser optical futhi kubangele ukuthi indawo yokumaka ishintshe. Ngokuphathelene nokudlidliza, isici sokunciphisa okuphezulu kwegranite singanciphisa ukudlidliza okungu-100Hz zingakapheli imizuzwana engu-0.12, kuyilapho insimbi ephonswe idinga imizuzwana engu-0.9. Ngaphansi kwezimo zokudlidliza ezivame kakhulu, ukunemba kokucubungula kwemishini enezisekelo zensimbi ephonswe kuthambekele kakhulu ekushintsheni.

Iii. Ukuqhathaniswa Kwedatha Yokunciphisa Ukunemba

Ngokusho kokuhlolwa kwezikhungo zobungcweti, ngesikhathi sokumakwa kwe-laser ye-picosecond yamahora angu-8 okuqhubekayo, ukuncishiswa kokunemba kokubeka kwe-XY-axis kwemishini enesisekelo se-granite kungaphakathi kuka-±0.5μm. Ukuncishiswa kokunemba kwemishini yesisekelo sensimbi ecijile kufinyelela ku-±3μm, ngomehluko omkhulu. Endaweni elingisiwe enokushintsha kwezinga lokushisa okungu-5℃, iphutha lokuguqulwa kokushisa kwemishini yesisekelo se-granite liyi-+ 0.8μm kuphela, kanti elomshini wesisekelo sensimbi ecijile liphakeme njengo-+ 12μm.

Ngaphezu kwalokho, ngokombono wokusetshenziswa kwesikhathi eside, izinga lokwahlulela kabi izisekelo ze-granite lingu-0.03% kuphela, kuyilapho izinga lokwahlulela kabi izisekelo zensimbi ephonswe liphezulu njengo-0.5% ngenxa yezinkinga zokuzinza kwesakhiwo. Le datha ikhombisa ngokugcwele ukuthi ngaphansi kwezidingo ezinembile kakhulu zokucubungula izinga le-picosecond, inzuzo yokuzinza kwesisekelo se-granite ibalulekile.

Iv. Iziphakamiso Zokuthuthukisa kanye Nezicelo Ezisebenzayo

Kumabhizinisi aphishekela ukunemba kokucubungula okuphelele, ukuthuthukisa isisekelo sensimbi ephonswe esisekelweni segranite kuyindlela ephumelelayo yokuthuthukisa ukusebenza kwemishini. Ngesikhathi senqubo yokuthuthukisa, kufanele kuqashelwe ukunemba kokucubungula kwesisekelo segranite ukuqinisekisa ukuthi ukuthamba komphezulu kuhlangabezana nezidingo zomklamo. Ngesikhathi esifanayo, ngokuhlanganiswa namadivayisi asizayo njengohlelo lokuhlukanisa ukudlidliza komoya, ukusebenza kokumelana nokudlidliza kwemishini kungathuthukiswa kakhulu.

Njengamanje, ezimbonini ezifana nokukhiqizwa kwe-semiconductor chip kanye nokucubungula izingxenye ze-optical precision, imishini yokumaka ye-laser enezisekelo ze-granite iye yamukelwa kabanzi, okuthuthukisa ngempumelelo isivuno somkhiqizo kanye nokusebenza kahle kokukhiqiza. Isibonelo, ngemuva kokuba umenzi othile wezingxenye ze-optical ethuthukise imishini yesisekelo sensimbi ephonswe, izinga lokufaneleka kokunemba komkhiqizo lenyuke lisuka ku-82% laya ku-97%, futhi ukusebenza kahle kokukhiqiza kwathuthukiswa kakhulu.

Ekuphetheni, ekuthuthukisweni kwesisekelo semishini yokumaka i-laser yezinga le-picosecond, i-granite, enokuqina kwayo okuvelele kokushisa, ukusebenza okuphezulu kokudambisa kanye nekhono lokugcina ukunemba kwesikhathi eside, isibe yisinqumo esihle kakhulu kunensimbi ephonswe ngensimbi. Amabhizinisi angakhetha ngokunengqondo izinto eziyisisekelo ngokusekelwe ezidingweni zawo zokucubungula kanye nesabelomali ukuze afinyelele ukuthuthukiswa okuphelele kokusebenza kwemishini.

Isikhathi sokuthunyelwe: Meyi-19-2025