Emkhakheni wemishini yokumaka ye-laser yeleveli ye-picosecond, ukunemba kuyinkomba eyinhloko yokuhlola ukusebenza kwesisetshenziswa. Isisekelo, njengesiphathi esiyinhloko sesistimu ye-laser kanye nezingxenye ezinembayo, okubalulekile kuthinta ngokuqondile ukuzinza kokucubungula ukunemba. I-Granite ne-cast iron, njengezinto ezimbili eziyisisekelo ezivamile, zinomehluko omkhulu ezicini zokunemba zokuncishiswa ngesikhathi sokucutshungulwa kwe-ultra-fine yeleveli ye-picosecond. Lesi sihloko sizohlaziya ngokujulile izinzuzo zokusebenza kanye nokubi kwakho kokubili ukuze kunikezwe isisekelo sesayensi sokuthuthukiswa kwemishini. .

Izinto ezibonakalayo zinquma isisekelo sokunemba

I-Granite empeleni iyidwala elivuthayo elakhiwe ngezinqubo ze-geological phakathi namakhulu ezigidi zeminyaka. Isakhiwo saso sekristalu sangaphakathi siminyene futhi siyafana, sine-coefficient yomugqa yokwandisa ephansi njengo-0.5-8 × 10⁻⁶/℃, uma kuqhathaniswa naleyo yama-alloys anembayo njengensimbi ye-indium. Lesi sici senza ukuguqulwa kwayo kobukhulu kucishe kungabi nandaba lapho izinga lokushisa lendawo lishintshashintsha, kugwenywe ngempumelelo indlela yokubona kanye namaphutha emishini abangwa ukunwetshwa nokufinyela kwe-thermal. Ngaphezu kwalokho, ukuminyana kwegwadle kuphezulu njengokungu-2.6-2.8g/cm³, ngokwemvelo enamandla okumunca ukudlidliza. Inganciphisa ngokushesha ukudlidliza kwe-high-frequency okukhiqizwa phakathi nokucubungula i-laser, iqinisekise ukuzinza kwesistimu yokubona kanye nezingxenye ezihambayo. .

Izisekelo ze-cast iron zisetshenziswa kakhulu ngenxa yokusebenza kwazo okuhle kakhulu kanye nezinzuzo zezindleko. Isakhiwo esijwayelekile se-flake se-graphite yensimbi empunga siyinikeza ukusebenza okuthile kokumanzisa, okungamunca cishe u-30% kuya ku-50% wamandla okudlidliza. Kodwa-ke, i-coefficient yokwanda okushisayo kwensimbi ekhonjiwe cishe i-10-12 × 10⁻⁶/℃, okuyizikhathi ezingu-2-3 kune-granite. Ngaphansi kokunqwabelana kokushisa okukhiqizwa ukucubungula okuqhubekayo kwesikhathi eside, ukuwohloka kwe-dimensional kujwayele ukwenzeka. Phakathi naleso sikhathi, kukhona ukucindezela ngaphakathi kwensimbi ekhonjiwe. Njengoba ingcindezi ikhishwa phakathi nenqubo yokusebenzisa, ingase ibangele izinguquko ezingenakuhlehliswa ekucabaneni kanye ne-perpendicularity yesisekelo. .

Indlela yokunciphisa enembile ekucutshungulweni kweleveli ye-picosecond

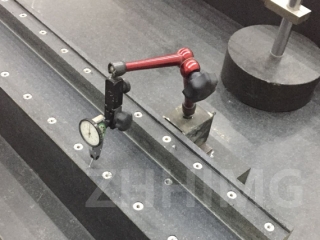

I-Picosecond laser processing, enezici zayo ze-ultra-short pulse, ingafinyelela ukucubungula okuhle ezingeni le-sub-micron noma izinga le-nanometer, kodwa futhi ibeka izidingo eziqinile zokuzinza kwemishini. Isisekelo se-granite, nesakhiwo saso sangaphakathi esizinzile, singalawula impendulo yokudlidliza ezingeni le-sub-micron ngaphansi komthelela we-laser we-high-frequency, igcine ngempumelelo ukunemba kokuma kokugxila kwe-laser. Idatha elinganisiwe ibonisa ukuthi umshini wokumaka we-laser onesisekelo segwadle usagcina ukuchezuka kobubanzi bomugqa ngaphakathi kuka-±0.5μm ngemva kokucubungula okuqhubekayo kwamahora angu-8 we-piccosecond. .

Uma isisekelo sensimbi sivezwa ekudlidlizeni kwefrikhwensi ephezulu ye-picosecond laser, ukwakheka okusanhlamvu kwangaphakathi kuzobhekana nokukhathala okuncane ngenxa yomthelela oqhubekayo, okuholela ekwehleni kokuqina kwesisekelo. Ukuqapha idatha evela ebhizinisini elithile elikhiqiza ama-semiconductor libonisa ukuthi ngemva kwezinyanga eziyisithupha zokusebenza, izinga lokunciphisa ukunemba kokucutshungulwa kwemishini enezisekelo zensimbi ecijile lifinyelela ku-12%, elibonakala ikakhulukazi njengokwanda kobukhali bemiphetho yemigqa kanye nokwanda kwamaphutha okuma. Khonamanjalo, insimbi eyinsimbi izwela kakhulu kumswakama wendawo. Ukusetshenziswa isikhathi eside kujwayele ukugqwala, kuqhubekisele phambili ukusheshisa ukuwohloka kokunemba. .

Ukuqinisekiswa komehluko wokusebenza ezinhlelweni ezingokoqobo

Emkhakheni wokucutshungulwa kwengxenye ye-elekthronikhi ye-3C, ibhizinisi elaziwayo lenze uhlolo lokuqhathanisa ekusebenzeni kwemishini yezinhlobo ezimbili zezisekelo zezinto ezibonakalayo. Ocwaningweni, imishini emibili yokumaka i-picosecond laser enokucushwa okufanayo ifakwe ngokulandelana izisekelo ze-granite nezinsimbi ezisansimbi zokusika nokumaka ingilazi yezikrini zamaselula ezinobubanzi obungu-0.1mm. Ngemuva kwamahora angu-200 okucubungula okuqhubekayo, izinga lokugcinwa kokunemba kokucubungula kwesisekelo se-granite kwaba ngu-98.7%, kanti lelo lezinto zensimbi ezisansimbi lalingu-86.3 kuphela%. Unqenqema lwengilazi ecutshungulwe yilo lwakamuva lubonise ukukhubazeka okusobala kwe-sawtooth. .

Ekwenziweni kwezingxenye ze-aerospace, idatha yokuqapha yesikhathi eside yesikhungo esithile socwaningo ikhombisa ngokunembile umehluko: Umshini wokumaka we-laser onesisekelo segwadle unokuncipha kokunemba okuqongelelekayo okungaphansi kuka-3μm phakathi nempilo yesevisi yeminyaka emihlanu; Kodwa-ke, ngemva kweminyaka emithathu, iphutha lokucubungula le-cast iron base base ebangelwa ukuwohloka kwesisekelo selidlule izinga lenqubo lika-±10μm, futhi ukulinganisa kokunemba komshini okuphelele kufanele kwenziwe. .

Iziphakamiso zokuthuthukisa izinqumo

Uma amabhizinisi ethatha ukunemba okuphezulu nokucubungula okuzinzile komjikelezo omude njengezidingo zawo eziyinhloko, ikakhulukazi emikhakheni efana nama-semiconductor chips kanye nezingxenye ze-optical enembayo, izisekelo ze-granite, ezinokuzinza kwazo okuvelele okushisayo kanye nokumelana nokudlidliza, kuyisinqumo esihle sokuthuthukisa. Nakuba izindleko zayo zokuqala zokuthenga ziphakeme ngo-30% kuya ku-50% kunezo zensimbi ecijile, ngokombono wezindleko zomjikelezo wempilo ophelele, imvamisa encishisiwe yokulinganisa okunembayo kanye nesikhathi sokuphumula semishini yokunakekelwa kungathuthukisa kakhulu izinzuzo zizonke. Ezimweni zohlelo lokusebenza ezinezidingo eziphansi zokunemba kokucubungula kanye nesabelomali esilinganiselwe, izisekelo zensimbi ezisansimbi zisengasetshenziswa njengesixazululo sezinguquko ngaphansi kwesisekelo sokulawula ngokunengqondo indawo yokusetshenziswa. .

Ngokuqhathanisa ngokuhlelekile izici zokunciphisa ukunemba kwe-granite ne-cast iron ekucubunguleni izinga le-piccond, kungabonakala ukuthi ukukhetha isisekelo esifanelekile kuyisinyathelo esibalulekile sokuthuthukisa ukunemba kokucubungula nokuthembeka komshini wokumaka we-laser. Amabhizinisi kufanele, ngokucabangela izidingo zawo zobuchwepheshe kanye nokucatshangelwa kwezindleko, enze izinqumo zesayensi ngohlelo lokuthuthukisa isisekelo ukuze anikeze isisekelo esiqinile semishini yokukhiqiza okusezingeni eliphezulu. .

Isikhathi sokuthumela: May-22-2025