Ekukhiqizeni nasekubunjiniyeleni okunekhwalithi ephezulu, ukusebenza komshini akunqunywa nje kuphela ngama-drive awo, izilawuli, noma isofthiwe, kodwa ngokuyisisekelo ngesisekelo sawo sesakhiwo. Izisekelo zamathuluzi omshini kanye nezinhlangano zokubhekisela kuthinta ngqo ukunemba, ukuziphatha kokudlidliza, ukuzinza kokushisa, kanye nokuthembeka kwesikhathi eside. Njengoba ukubekezelelana kokukhiqiza kuqhubeka nokuqina kuzo zonke izimboni ezifana nezindiza, imishini ye-semiconductor, i-optics, kanye nokuzivumelanisa okuthuthukisiwe, ukukhethwa kwezinto zezisekelo zomshini sekuyinto ethathwa njengesinqumo sobunjiniyela obusezingeni eliphezulu.

Phakathi kwezixazululo ezivame ukuhlolwa kakhulu kukhona izisekelo zomshini we-epoxy granite, izisekelo zamathuluzi omshini wensimbi yendabuko, kanye nezinhlangano zemvelo ze-granite enembile. Ngesikhathi esifanayo, amapuleti obuso be-granite ahlala eyizingxenye ezibalulekile zokubhekisela kuzo zombili izindawo zokukhiqiza kanye ne-metrology. Lesi sihloko sinikeza ukuhlaziywa okuhlelekile kwalezi zinto kanye nezingxenye, sihlola izinzuzo kanye nemikhawulo yazo, futhi sichaza ukuthi izinhlangano ze-granite enembile zisekela kanjani izinhlelo zokukhiqiza zesimanje. Siphinde sigcizelele indlela i-ZHHIMG eletha ngayo izixazululo ze-granite eziklanywe ngobunjiniyela ezihambisana nezidingo zamakhasimende ezimboni zomhlaba wonke.

Isisekelo Somshini We-Epoxy Granite: Izici kanye Namacala Okusetshenziswa

I-Epoxy granite, ebizwa nangokuthi ikhonkrithi ye-polymer noma i-mineral casting, iyi-izinto ezihlanganisiweYakhiwe ngokubopha ama-mineral aggregates nge-epoxy resin. Ithole ukunakwa njengenye into eyisisekelo yomshini ngenxa yezici zayo zokudambisa ukudlidliza kanye namakhono okubumba aguquguqukayo.

Enye yezinzuzo eziyinhloko zesisekelo somshini we-epoxy granite ukuthi i-epoxy granite inamandla kakhulu ngaphakathi. Uma iqhathaniswa nezakhiwo zensimbi, i-epoxy granite inganciphisa kakhulu ukudluliselwa kokudlidliza, ithuthukise ukuqeda kobuso kanye nokuqina okuguquguqukayo kwezinye izinhlelo zokusebenza zomshini. Ngaphezu kwalokho, amajiyometri ayinkimbinkimbi, iziteshi zangaphakathi, kanye nezingxenye ezifakiwe zingahlanganiswa ngesikhathi senqubo yokukhipha, kunciphisa izidingo zesibili zomshini.

Kodwa-ke, i-epoxy granite nayo inemikhawulo. Ukuzinza kwesikhathi eside kuncike kakhulu ekwakhiweni kwe-resin, ikhwalithi yokwelapha, kanye nezimo zemvelo. Ukuguga kwe-resin, ukuzwela kwezinga lokushisa, kanye nemiphumela engaba khona yokukhukhuleka kumele kucatshangelwe ngokucophelela ekusetshenzisweni okunembile kakhulu noma okuhlala isikhathi eside. Ngenxa yalokho, i-epoxy granite ivame ukukhethwa ngamathuluzi omshini anokunemba okuphakathi kunezinhlelo ezidinga ukunemba okukhulu eminyakeni eminingi yenkonzo.

Isisekelo Samathuluzi Omshini Wensimbi Ophonswe: Isiko Nemingcele

Insimbi ephothiwe ibilokhu iyimpahla yendabuko ekhethwayo yezisekelo zamathuluzi omshini iminyaka engaphezu kwekhulu. Ukuthandwa kwayo kuvela ekusebenzeni kahle kwemishini, ukudambisa okunengqondo, kanye nezinqubo zokukhiqiza ezisunguliwe.Imishini ye-CNCkanye nemishini yenhloso ejwayelekile iyaqhubeka nokuthembela ezakhiweni zensimbi ephonswe ngensimbi.

Naphezu kwalezi zinzuzo, izisekelo zamathuluzi omshini wensimbi ephonswe zibonisa izinkinga ezingokwemvelo ezindaweni ezinembe kakhulu. Ukucindezeleka okusele okwethulwa ngesikhathi sokukhipha nokulungisa kungaholela ekuguqukeni kancane kancane ngokuhamba kwesikhathi, ngisho nangemva kokwelashwa kokunciphisa ukucindezeleka. Insimbi ephonswe nayo ibucayi kakhulu ekukhuleni kokushisa kanye nokushintshashintsha kwezinga lokushisa kwemvelo, okungathinta ngqo ukunemba kokubeka.

Ukumelana nokugqwala kungenye into okufanele icatshangelwe. Izisekelo zensimbi ephothiwe ngokuvamile zidinga izembozo ezivikelayo kanye nezindawo ezilawulwayo ukuvimbela ukungcoliswa, ikakhulukazi ezindaweni ezinomswakama noma eziseduze negumbi elihlanzekile. Lezi zici ziye zashukumisela abakhiqizi bemishini ukuthi bahlole ezinye izinto zokusetshenziswa ezifuna ukuzinza okuphezulu kanye nokugcinwa okuncane.

Ukuhlanganiswa kweGranite Okuqondile: Inzuzo Yesakhiwo

I-granite eqondile imelela indlela ehluke ngokuphelele ekuklanyweni kwesakhiwo somshini. Yakhiwe nge-granite yemvelo eye yaguga eminyakeni eyizigidi, i-granite ayinayo ingcindezi futhi ayi-isotropic ngokwemvelo. Lokhu kuzinza kwemvelo kunikeza inzuzo ebalulekile ekugcineni ukunemba kwe-geometric kwesikhathi eside.

I-precision granite assemblies yenziwa ngezinqubo zokugaya nokubopha ezilawulwayo, kufinyelela ubucaba, ukunemba, kanye nokuma okuqondile ezingeni le-micron. Ngokungafani nezinto ezibunjiwe noma ezihlanganisiwe, i-granite ayihlushwa ukukhululeka kokucindezeleka kwangaphakathi, okwenza ifaneleke kakhulu ekusetshenzisweni okunembile kakhulu nokuphila isikhathi eside.

Ngaphezu kokuqina kobukhulu, i-granite inikeza ukudambisa okuhle kakhulu kokudlidliza kanye ne-coefficient ephansi yokwanda kokushisa. Lezi zakhiwo zinegalelo ekusebenzeni okuthuthukisiwe okuguquguqukayo, ukwehla kokushelela kokushisa, kanye nokunemba okuqhubekayo phakathi nezikhathi zokusebenza ezinde. I-granite futhi ayinamandla kazibuthe futhi ayimelani nokugqwala, okwenza kube lula ukusetshenziswa emakamelweni okuhlanza, ezinhlelweni zokukhanya, kanye nasezindaweni zokuhlola ngokunemba.

Ipuleti Lomphezulu Wegranite: Isisekelo Sereferensi Eqondile

Ipuleti lobuso le-granite lingenye yezinto eziqashelwa kakhulu futhi ezibaluleke kakhuluizingxenye ze-granite ezinembileIsebenza njengendilinga eyisicaba yokubhekisela, isekela ukuhlolwa kobukhulu, ukulinganiswa, kanye nezinqubo zokuhlanganisa kuzo zonke izimboni zokukhiqiza.

Amapuleti obuso begranite asetshenziswa kakhulu emalabhorethri okulawula ikhwalithi, ezindaweni zokuhlola umkhiqizo, kanye namagumbi okukala. Ukumelana nokuguguleka kwawo kanye nokuqina kwawo kuvumela ukuthi alondoloze ukunemba isikhathi eside ngaphandle kokulungiswa okuningi. Uma kuqhathaniswa namapuleti obuso bensimbi ecijile, amapuleti egranite anikeza ukumelana nokugqwala okuphezulu, ukuzwela okuphansi kokushisa, kanye nemvamisa yokulinganisa kabusha encishisiwe.

Ezindaweni zokukhiqiza ezithuthukisiwe, amapuleti omhlaba we-granite ahlanganiswa kakhulu emihlanganweni yomshini, amapulatifomu okukhanya, kanye neziteshi zokuhlola ezenzakalelayo, okwandisa indima yawo ngale kwamathuluzi endabuko okukala azimele.

Umbono Wokuqhathanisa: Ukukhethwa Kwezinto Ezisekelo Zomshini

Uma kuqhathaniswa izisekelo zomshini we-epoxy granite, izisekelo zamathuluzi omshini wensimbi ephothiwe, kanye nokuhlanganiswa kwe-granite okunembile, ukukhethwa kwezinto kufanele kuqondiswe yizidingo zohlelo lokusebenza kunezindleko zokuqala zodwa.

I-Epoxy granite inikeza ukuguquguquka komklamo kanye nokunciphisa umswakama okunamandla, okwenza ifaneleke imishini ezwela ukudlidliza kodwa enembile ngokumaphakathi. Insimbi ephothiwe ihlala ifanelekile kumathuluzi omshini avamile lapho ukusebenza kahle kwezindleko kanye nezinqubo zokukhiqiza ezisunguliwe kuyizinto eziza kuqala. Nokho, izinhlangano ze-precision granite zinikeza ukuzinza okungenakuqhathaniswa kwesikhathi eside, ukusebenza kokushisa, kanye nokugcinwa kokunemba, okwenza kube yisisombululo esithandwayo semishini enembile kakhulu kanye nezinhlelo ze-metrology ezithuthukisiwe.

Ukusebenza komjikelezo wokuphila kuyindlela yokuhlola ebaluleke kakhulu. Nakuba ukutshalwa kwezimali kokuqala ekuhlanganisweni kwe-granite enembile kungaba phezulu, ukugcinwa okuncishisiwe, izikhawu zokulinganisa ezinde, kanye nokunemba okuqhubekayo kuvame ukuholela ezindlekweni eziphansi zobunikazi.

Amathrendi Emboni kanye Namasu Okuklama Aguqukayo

Izitayela eziningana zemboni zisheshisa ukwamukelwa kwezakhiwo zemishini esekelwe ku-granite. Ukukhula kokukhiqizwa kwe-semiconductor, i-optics, kanye nokucutshungulwa kwe-laser kuye kwabangela isidingo samapulatifomu azinzile kakhulu anamandla okunemba kwe-sub-micron. Ukuzenzakalela kanye nokukhiqizwa kwedijithali kugcizelela kakhulu isidingo sezisekelo zesakhiwo ezinokwethenjelwa ezingasebenza ngokuqhubekayo ngokushelela okuncane.

Abaklami bamathuluzi omshini baqhubeka nokwamukela izakhiwo ezihlanganisiwe ezihlanganisa izisekelo ze-granite nama-motor aqondile, ama-air bearings, kanye nezinhlelo zokulawula ezithuthukisiwe. Kulezi zilungiselelo, izinhlangano ze-granite zinikeza ukuzinza okudingekayo ukuze kufezwe ngokugcwele amandla okusebenza kobuchwepheshe bokunyakaza nokulinganisa obusezingeni eliphezulu.

Amakhono e-ZHHIMG ekukhiqizeni i-Precision Granite

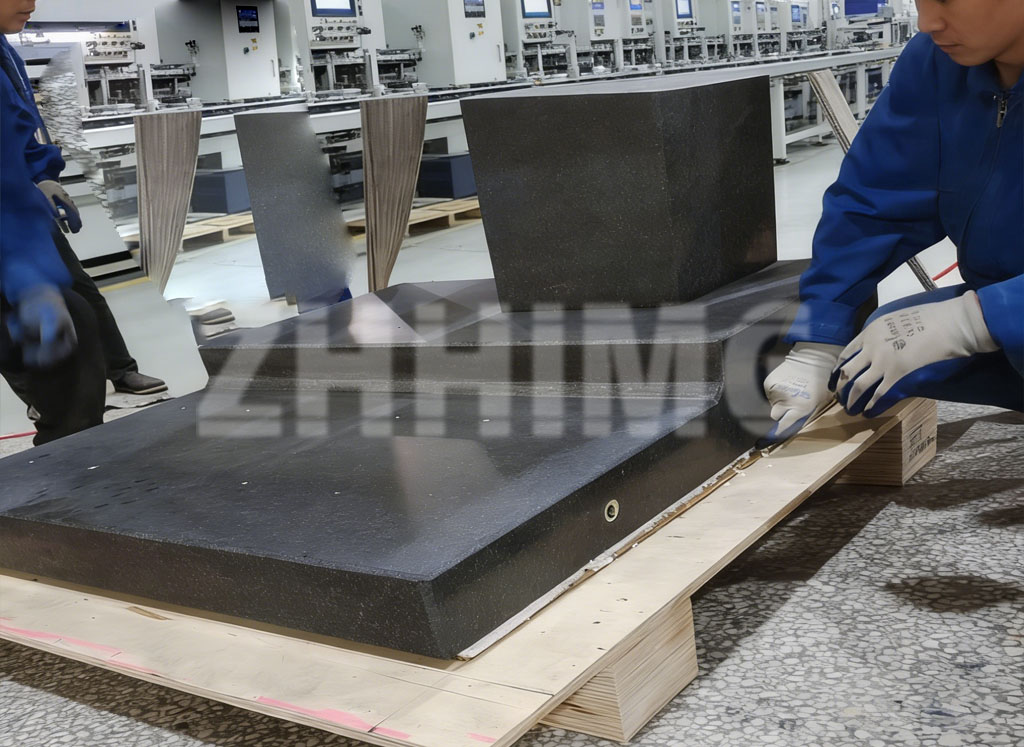

I-ZHHIMG igxile ekuklanyweni nasekukhiqizweni kwezinhlangano ze-granite ezinembile zamakhasimende ezimboni zomhlaba wonke. Isebenzisa ubuchwepheshe bokugaya obuphezulu be-granite emnyama kanye nobuchwepheshe obuthuthukisiwe bokugaya ngokunembile, i-ZHHIMG ikhiqiza izisekelo zomshini we-granite, amapuleti obuso, kanye nezinhlangano ezenziwe ngokwezifiso ezihlangabezana nezindinganiso eziqinile zokunemba zomhlaba wonke.

Izinqubo zokukhiqiza zenkampani zenziwa ngaphansi kwezimo zemvelo ezilawulwayo, ngokuhlolwa okuphelele esigabeni ngasinye ukuqinisekisa ukuhambisana nokuthembeka. I-ZHHIMG isekela amakhasimende kuyo yonke imisebenzi yokukhiqiza amathuluzi omshini, izinhlelo ze-metrology, imishini ye-semiconductor, kanye nokwenza izinto ngokuzenzakalela okuthuthukisiwe.

Ngokubambisana eduze nabaklami bemishini nonjiniyela, i-ZHHIMG iletha izixazululo ze-granite ezihlanganiswa kalula nokwakhiwa kwemishini okuyinkimbinkimbi futhi zisekele izinhloso zokusebenza zesikhathi eside.

Isiphetho

Njengoba ukukhiqiza kuqhubeka nokuqhubekela phambili ekuqondeni okuphezulu kanye nokuhlanganiswa okukhulu kwesistimu, ukubaluleka kwezinto eziyisisekelo zomshini kanye nezinhlangano zokubhekisela kuzokhula kuphela. Izisekelo zomshini we-granite we-Epoxy kanye nezisekelo zamathuluzi omshini wensimbi ephonswe yinsimbi ngayinye igcina ukubaluleka ngaphakathi kwebanga elithile lokusetshenziswa, kodwa izinhlangano ze-granite ezinembile zinikeza izinzuzo ezihlukile ekuzinzeni, ekunembileni, kanye nokusebenza komjikelezo wokuphila.

Amapuleti omhlaba we-granite kanye nezakhiwo zomshini ezisekelwe ku-granite zihlala ziyizinto eziyisisekelo kubunjiniyela besimanje bokunemba. Ngobuchwepheshe obuzinikele ekukhiqizeni i-granite enembile, i-ZHHIMG isesimweni esihle sokusekela amakhasimende omhlaba wonke afuna izixazululo ezithembekile, zesikhathi eside zokukhiqiza okuthuthukisiwe kanye nezinhlelo zokusebenza ze-metrology.

Isikhathi sokuthunyelwe: Jan-21-2026