Ezweni elisheshayo lokukhiqizwa kwezinto zikagesi, lapho amasekethe encipha khona futhi ubunzima bukhuphuka, isidingo sokunemba asikaze sibe phezulu. Ikhwalithi yebhodi lesifunda eliphrintiwe (i-PCB) iyisisekelo sanoma iyiphi idivayisi kagesi, kusukela ku-smartphone kuya kusithwebuli sezokwelapha. Yilapho kuvela khona iqhawe elivame ukunganakwa: ipulatifomu ye-granite enembile. Kwa-ZHONGHUI Group (ZHHIMG®), sizibonele mathupha ukuthi le nto ebonakala ilula ibe kanjani isisekelo esithule, esingashukumi sezinqubo zokuhlola ezibucayi kanye nokukhiqiza embonini ye-elekthronikhi, ikakhulukazi ekuhlolweni kwe-PCB. Izinhlelo zokusebenza ziyahlukahluka, kodwa zonke zihlanganyela isidingo esifanayo sesisekelo esizinzile, esithe shí, nesithembekile.

Inselele Eyinhloko Yokukhiqiza i-PCB

Ama-PCB ayisimiso sezinzwa sezinto zikagesi zanamuhla. Ayinethiwekhi ebucayi yezindlela zokuhambisa umoya, futhi noma yiliphi iphutha—ukuklwebheka okuncane, imbobo engaqondile, noma ukugoba okuncane—kungenza ingxenye ingasebenzi. Njengoba amasekethe eba mancane kakhulu, amathuluzi asetshenziswa ukuwahlola kumele abe ama-oda amakhulu anembe kakhudlwana. Yilapho inselele enkulu ikhona: uqinisekisa kanjani ukunemba okuphelele lapho yona kanye imishini eyenza ukuhlolwa ibhekene nokwanda kokushisa, ukudlidliza, kanye nokuguqulwa kwesakhiwo?

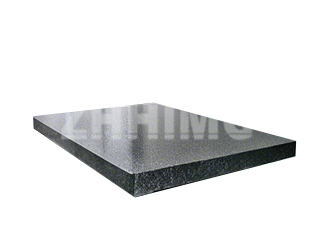

Impendulo, kwabaningi babakhiqizi be-elekthronikhi abahamba phambili emhlabeni, ilele ezimpahleni zomzimba ezihlukile ze-granite. Ngokungafani nezinsimbi, ezithinteka kakhulu yizinguquko zokushisa nokudlidliza, i-granite inikeza izinga lokuzinza elingenakuqhathaniswa. I-ZHHIMG® Black Granite yethu ine-coefficient ephansi yokwanda kokushisa kanye nezakhiwo ezinhle kakhulu zokunciphisa ukudlidliza, okwenza kube yinto efanelekile yesisekelo se-metrology esizinzile. Lokhu kuvumela imishini yokuhlola ukuthi isebenze ngokunemba kwangempela, ingonakaliswa umsindo wemvelo.

Izicelo Eziyinhloko Ekuhlolweni kwe-PCB kanye ne-Electronics

Amapulatifomu e-granite aqondile avela ku-ZHHIMG® ayingxenye ebalulekile yezigaba eziningana ezibalulekile zokukhiqizwa kwezinto zikagesi kanye nokulawulwa kwekhwalithi:

1. Ukuhlolwa Okuzenzakalelayo Kokukhanya (i-AOI) kanye Nokuhlolwa kwe-X-ray: Imishini ye-AOI kanye ne-X-ray iyindlela yokuqala yokuzivikela ekulawulweni kwekhwalithi. Iskena ngokushesha ama-PCB ukuze ithole amaphutha afana nama-short circuits, i-opens, kanye nezingxenye ezingaqondile. Lezi zinhlelo zithembele endaweni yokubhekisela eyisicaba ngokuphelele ukuqinisekisa ukuthi isithombe esithathwe asinakho ukuphambuka. Isisekelo se-granite sinikeza lesi sisekelo esiyisicaba kakhulu, esizinzile, siqinisekisa ukuthi i-optics yomshini noma umthombo we-X-ray kanye ne-detector zihlala zinobuhlobo obuqinile nobunembile. Amapulatifomu ethu e-granite angenziwa ngokusicaba kwama-micron ambalwa nje, ngisho nasezingeni le-nanometer ukuze kusetshenziswe kakhulu, ngenxa yabachwepheshe bethu abanolwazi abaneminyaka engaphezu kwengu-30 yobuchwepheshe bokugoqa ngesandla.

2. Imishini Yokubhoboza ye-PCB: Ukudala izinkulungwane zemigodi emincane ku-PCB kudinga ukunemba okukhulu. Isakhiwo sonke somshini wokubhoboza, okuhlanganisa nekhanda lokubhoboza kanye netafula le-XY, kumele sakhiwe esisekelweni esingeke sigobe noma sishintshe. I-Granite inikeza lokhu kuzinza, iqinisekisa ukuthi yonke imigodi ibhobozwa endaweni eqondile echazwe kufayela lomklamo. Lokhu kubaluleke kakhulu kuma-PCB anezingqimba eziningi, lapho imigodi engaqondile ingalimaza ibhodi lonke.

3. Imishini Yokulinganisa Ehlanganisiwe (ama-CMM) kanye Nezinhlelo Zokulinganisa Umbono (ama-VMS): Le mishini isetshenziselwa ukuqinisekisa ubukhulu bama-PCB nezinye izingxenye ze-elekthronikhi. Idinga isisekelo esinokunemba okumangalisayo kwejometri. Amapulatifomu ethu e-granite asebenza njengesisekelo esiyinhloko sama-CMM, enikeza indiza yokubhekisela ephelele lapho kuthathwa khona zonke izilinganiso. Ukuqina okungokwemvelo kwe-granite kuqinisekisa ukuthi isisekelo asiguquguquki ngaphansi kwesisindo somshini, kugcina inkomba efanayo ye-probe yokulinganisa.

4. Imishini Yokucubungula Nokuqopha Nge-Laser: Ama-laser anamandla amakhulu asetshenziselwa ukusika, ukuqopha, nokumaka amabhodi wesekethe. Indlela ye-laser kumele iqine kakhulu ukuqinisekisa ukusika okuhlanzekile nokunembile. Isisekelo se-granite sinikeza ukuncibilikisa okudingakalayo kokudlidliza kanye nokuqina kokushisa ukugcina ikhanda le-laser kanye nomsebenzi wokusebenza kuqondile kahle kuyo yonke inqubo.

Inzuzo ye-ZHHIMG® ku-Electronics

Ubambiswano lwethu nezinkampani ezinkulu ze-elekthronikhi kanye nokuzibophezela kwethu kwiNqubomgomo Yekhwalithi ethi, “Ibhizinisi elinembile alikwazi ukuba nzima kakhulu,” yikona okusenza sahluke. Siyaqonda ukuthi emkhakheni we-elekthronikhi, akukho ukukopela, akukho ukufihla, akukho ukudukisa uma kukhulunywa ngekhwalithi.

Indawo yethu yokusebenzela elawulwa yisimo sezulu engu-10,000m2 kanye namathuluzi okulinganisa ayinkimbinkimbi, okuhlanganisa nama-interferometer e-laser e-Renishaw, aqinisekisa ukuthi yonke isisekelo se-granite esiyikhiqizayo ifanelana kahle nezidingo zeklayenti. Asibona nje abaphakeli; singumlingani osebenzisanayo ekuthuthukiseni ubuchwepheshe. Embonini lapho ingxenye encane yemilimitha ingaba khona umehluko phakathi kwempumelelo nokwehluleka, i-ZHHIMG® inikeza isisekelo esizinzile, esinembile, nesinokwethenjelwa imboni ye-elekthronikhi ethembele kuso ukwakha ikusasa.

Isikhathi sokuthunyelwe: Septhemba-28-2025