Ekwakhiweni kwepulatifomu entantayo yomoya ocindezelwe ngokunemba okungaguquki, ukukhetha isisekelo kudlala indima ebalulekile ekusebenzeni kwepulatifomu iyonke. Isisekelo sokunemba kwe-granite kanye nesisekelo sensimbi ephonswe ngensimbi kunezici zazo, futhi kukhona umehluko osobala ngobukhulu obubalulekile njengokuqina, ukugcinwa kokunemba, ukuqina kanye nezindleko.

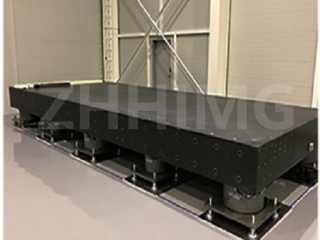

Okokuqala, ukuzinza: isakhiwo semvelo esiminyene nesensimbi

Ngemva kwezigidi zeminyaka yezinguquko zejiyoloji, i-granite ihlanganiswa eduze yi-quartz, i-feldspar kanye nezinye izimbiwa ukuze kwakhiwe isakhiwo esiminyene kakhulu nesifanayo. Lapho kubhekene nokuphazamiseka kwangaphandle, njengokudlidliza okunamandla okubangelwa ukusebenza kwemishini emikhulu endaweni yokusebenzela yasefektri, isisekelo se-granite singavimba futhi sinciphise ngempumelelo ngokuthembela esakhiweni saso esiyinkimbinkimbi sekristalu, esinganciphisa ubukhulu bokudlidliza bepulatifomu entantayo yomoya ocindezelwe ngokunemba ngamaphesenti angaphezu kuka-80, okuhlinzeka ngetshe eliyisisekelo lokusebenza elizinzile lepulatifomu ukuqinisekisa ukunyakaza okubushelelezi ngesikhathi sokucubungula noma ukuthola okunembile kakhulu. Isibonelo, enkambisweni ye-photolithography yokukhiqizwa kwe-chip kagesi, ukucaciswa okunembile kwamaphethini e-chip kuqinisekisiwe.

Isisekelo sensimbi ephonswe nge-iron-carbon alloy, kanti i-graphite yangaphakathi isatshalaliswa ngamashidi noma ama-sphere. Nakuba inekhono elithile lokudambisa ukudlidliza, ukufana kwayo kwesakhiwo akukuhle uma kuqhathaniswa ne-granite. Uma ibhekene nokuqina okuphezulu nokudlidliza okuqhubekayo, kunzima ngesisekelo sensimbi ephonswe ukunciphisa ukuphazamiseka kokudlidliza kube sezingeni elifanayo eliphansi njengesisekelo se-granite, okungaholela ekuphambukeni okuncane ekuhambeni kwepulatifomu yomoya ocindezelekile oqondile, okuthinta ukusebenza kahle kwepulatifomu emisebenzini yokunemba okukhulu.

Okwesibili, ukugcinwa kokunemba: izinzuzo zemvelo zokwandiswa okuphansi kanye nenselele yokushintsha kokushisa kwensimbi

I-Granite yaziwa ngokulingana kwayo okuphansi kakhulu kokukhula kokushisa, ngokuvamile ku-5-7 × 10⁻⁶/℃. Endaweni yokuguquguquka kwezinga lokushisa, usayizi wesisekelo sokunemba se-granite awushintshi kakhulu. Emkhakheni wezinkanyezi, ipulatifomu yokuntanta yomoya eqondile ye-hydrostatic yokulungiswa kahle kwelensi yethelesikopu ihambisana nesisekelo se-granite, noma ngabe umehluko wokushisa phakathi kwemini nobusuku ubalulekile, ingaqinisekisa ukuthi ukunemba kokubekwa kwelensi kugcinwa ezingeni le-submicron, kusize izazi zezinkanyezi ukuthi zibambe amandla angabonakali ezidalwa zasezulwini ezikude.

I-coefficient yokwanda kokushisa kwensimbi ephothiwe iphakeme kakhulu, ngokuvamile i-10-20 ×10⁻⁶/℃. Lapho izinga lokushisa lishintsha, usayizi wesisekelo sensimbi ephothiwe uyashintsha ngokusobala, okulula ukubangela ukuguqulwa kokushisa kwepulatifomu entantayo yomoya ocindezelekile oqondile, okuholela ekwehleni kokunemba kokunyakaza kwepulatifomu. Enqubweni yokugaya yamalensi optical azwela izinga lokushisa, ukuguqulwa kwesisekelo sensimbi ephothiwe ngaphansi kwethonya lokushisa kungabangela ukuphambuka kokunemba kokugaya kwelensi ngaphezu kwebanga elivunyelwe futhi kuthinte ikhwalithi yelensi.

Okwesithathu, ukuqina: ubulukhuni obukhulu betshe lemvelo kanye nokukhathala kwensimbi

Ubulukhuni begranite buphezulu, ubulukhuni be-Mohs bungafinyelela ku-6-7, ukumelana okuhle nokuguguleka. Elabhorethri yesayensi yezinto zokwakha, ipulatifomu yomoya ontantayo oqinile osetshenziswa njalo, isisekelo sayo segranite singamelana ngempumelelo nokulahlekelwa ukungqubuzana kwesikhathi eside, uma kuqhathaniswa nesisekelo esivamile, singandisa umjikelezo wokugcinwa kwepulatifomu ngaphezu kuka-50%, sinciphise izindleko zokugcinwa kwemishini, futhi siqinisekise ukuqhubeka komsebenzi wocwaningo lwesayensi. Kodwa-ke, izinto zegranite ziyaqhekeka, futhi kunengozi yokuqhekeka uma zithinteka ngengozi.

Isisekelo sensimbi ephonswe sinokuqina okuthile futhi akulula ukusiphula uma siphethe amandla athile okushaya. Kodwa-ke, enkambisweni yokunyakaza okuphezulu okuphindaphindayo kwepulatifomu entantayo yomoya ocindezelwe ngokunemba isikhathi eside, insimbi ephonswe ithambekele ekulimaleni kokukhathala, okuholela ezinguqukweni esakhiweni sangaphakathi, okuthinta ukunemba kokunyakaza kanye nokuqina kwepulatifomu. Ngesikhathi esifanayo, insimbi ephonswe ithambekele ekugqwaleni nasekugqwaleni ezindaweni ezinomswakama, okunciphisa ukuqina kwayo, ngokuphambene nalokho, isisekelo se-granite ekumelaneni nokugqwala singcono.

Okwesine, izindleko zokukhiqiza kanye nobunzima bokucubungula: izinselele zokumba amatshe emvelo kanye nokucubungula kanye nomkhawulo wenqubo yokubumba insimbi

Ukumbiwa nokuthuthwa kwezinto zokusetshenziswa ze-granite kuyinkimbinkimbi, futhi ukucubungula kudinga imishini nobuchwepheshe obuphezulu kakhulu. Ngenxa yobulukhuni bayo obuphezulu, ukuphuka, ukusika, ukugaya, ukupholisha nezinye izinqubo zivame ukuwohloka, ukuqhekeka, izinga eliphezulu lokulahla, okuholela ezindleleni zokukhiqiza eziphezulu.

Isisekelo sensimbi ephonswe ngensimbi ephonswe ngenqubo yokuphonswa evuthiwe, umthombo obanzi wezinto zokusetshenziswa kanye nezindleko eziphansi. Ngokusebenzisa isikhunta kungafinyelela ukukhiqizwa okukhulu, ukusebenza kahle kokukhiqiza okuphezulu. Kodwa-ke, ukuze kufezwe ukunemba okuphezulu kanye nokuzinza okufanayo nesisekelo segranite, inqubo yokuphonswa kanye nezidingo zangemva kokucubungula ziqinile kakhulu, zidinga ukushintshwa okunembile kanye nokwelashwa kokuguga, njll., futhi izindleko nazo zizokhuphuka kakhulu.

Ngamafuphi, isisekelo sokunemba kwe-granite sinezinzuzo ezibalulekile ezimweni zokusetshenziswa kwepulatifomu yokuntanta yomoya eqondile edinga ukunemba okuphezulu, ukuzinza kanye nokumelana nokuguguleka; Isisekelo sensimbi ephonswe sinezinzuzo ezithile ngezindleko nokuqina, futhi sifaneleka ngezikhathi lapho izidingo zokunemba ziphansi khona, ukuphishekela ukusebenza kahle kwezindleko kanye nendawo yokudlidliza kanye nokushisa kuzinzile.

Isikhathi sokuthunyelwe: Ephreli-09-2025