Esimweni esishintsha ngokushesha sokukhiqiza okuthuthukile, ukunemba kuseyiyona ndawo eyinhloko. Namuhla, ukusungula izinto ezintsha kuhlelwe ukuchaza kabusha amazinga embonini: i-Precision Marble Three-Axis Gantry Platform, isimanga sobunjiniyela esihlanganisa ukuzinza kwemvelo kwe-granite nomklamo wemishini osezingeni eliphezulu ukuze kufezwe ukunemba kwezinga le-micron okwakucatshangwa ukuthi akutholakali ezicelweni zezimboni.

Isayensi Ebangela Ukuzinza

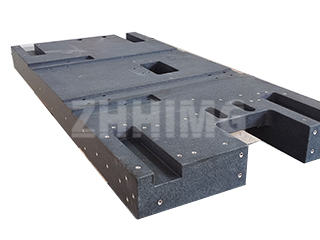

Enhliziyweni yalesi sinyathelo sobuchwepheshe kukhona ukukhetha okungalindelekile kwezinto ezibonakalayo: i-granite yemvelo. Isisekelo semabula esenziwe ngokunemba esingu-1565 x 1420 x 740 mm sepulatifomu asiyona nje indlela yokuklama—siyisisombululo sesayensi senselele endala yokugcina ukuzinza ezinhlelweni ezinembile kakhulu. “I-coefficient ephansi kakhulu yokwanda kokushisa kwe-granite (2.5 x 10^-6 /°C) kanye nezici ezimangalisayo zokunciphisa umswakama zinikeza isisekelo esimelana nokushintshashintsha kwezinga lokushisa kwemvelo kanye nokudlidliza kwemishini kangcono kakhulu kunezakhiwo zensimbi zendabuko,” kuchaza uDkt. Emily Chen, unjiniyela ophambili wemishini e-Precision Engineering Research Institute.

Le nzuzo yemvelo ihumusha ngqo kuma-metric okusebenza aguqula amakhanda kuzo zonke izimboni. Ipulatifomu ifinyelela ukuphindaphindeka okungu-±0.8 μm—okusho ukuthi ingabuyela kunoma yisiphi isikhundla ngokuphambuka okuncane kunobude bokukhanya okubonakalayo—kanye nokunemba kokubeka okungu-±1.2 μm ngemva kokukhokhelwa, okubeka indinganiso entsha yezinhlelo zokulawula ukunyakaza.

Ubuchwepheshe Bokuthuthuka Kwezobunjiniyela Ekuhambeni

Ngale kwesisekelo sayo esizinzile, ukwakheka kwe-gantry yesikhulumi enama-axis amathathu kuhlanganisa izinto ezintsha eziningana. I-X-axis inesistimu yokushayela okubili eqeda ukuguquguquka kwe-torsional ngesikhathi sokunyakaza ngesivinini esikhulu, kuyilapho zombili i-X ne-Y axes ziletha ukuhamba okuphumelelayo okungu-750 mm ngokunemba okungu-≤8 μm kokubili ezindizeni ezivundlile neziqondile. Leli zinga lokunemba kwejometri liqinisekisa ukuthi ngisho nezindlela eziyinkimbinkimbi ze-3D zigcina ukunemba kwe-sub-micron.

Amakhono okunyakaza kwesistimu afinyelela ibhalansi emangalisayo phakathi kwesivinini nokunemba. Ngenkathi isivinini sayo esiphezulu esingu-1 mm/s singase sibonakale sincane, senzelwe izinhlelo zokusebenza ezidinga ukulawulwa okuhle kanye nokuskena okuhamba kancane—lapho ukunemba kubaluleke ngaphezu kokunyakaza okusheshayo. Ngokuphambene nalokho, ikhono lokusheshisa le-2 G liqinisekisa ukusebenza okusabelayo kokuqala, okubalulekile ekugcineni ukudlula kwesivinini ezinqubweni zokuhlola ngokunemba.

Ngomthamo womthwalo ongu-40 kg kanye nesisombululo esingu-100 nm (0.0001 mm), le pulatifomu ivala igebe phakathi kokuphathwa okuncane okubucayi kanye nokuqina kwezimboni—ukuguquguquka okudala intshisekelo enkulu kuyo yonke imikhakha yokukhiqiza.

Ukuguqula Izimboni Ezibalulekile

Imiphumela yalokhu kuphumelela kokunemba idlulela emikhakheni eminingi yobuchwepheshe obuphezulu:

Ekwenziweni kwe-semiconductor, lapho ngisho namaphutha esikalini se-nanometer angenza ama-chip angasebenzi, ukuzinza kwepulatifomu kuguqula izinqubo zokuhlola i-wafer kanye nokuqondanisa i-photolithography. “Sibona amazinga okuthola amaphutha ethuthuka ngo-37% ezivivinyweni zokuqala,” kubika uMichael Torres, unjiniyela omkhulu wenqubo kumkhiqizi wemishini ye-semiconductor ohamba phambili. “Ukunciphisa ukudlidliza kwesisekelo semabula kususe i-micro-wobble eyayifihla izici ze-sub-50 nm ngaphambili.”

Ukukhiqizwa kwe-optical okunembile kungenye inzuzo. Izinqubo zokupholisha amalensi kanye nokuhlanganisa ezazidinga amahora amaningi okulungiswa ngesandla okucophelelayo manje zingenziwa ngokuzenzakalela ngokubeka kwepulatifomu i-sub-micron, kunciphisa izikhathi zokukhiqiza ngenkathi kuthuthukiswa ukuhambisana kokusebenza kwe-optical.

Ocwaningweni lwezokwelapha, le nkundla ivumela intuthuko ekuphathweni kweseli elilodwa kanye nokuthwebula izithombe ezincane ngesisombululo esiphezulu. UDkt. Sarah Johnson woMnyango Wobunjiniyela Bezokwelapha waseStanford uyaphawula, “Ukuzinza kusenza sikwazi ukugxila ezakhiweni zamaseli isikhathi eside, sithwebula izithombe zesikhathi eziveza izinqubo zebhayoloji ezazifihliwe ngaphambilini ngokukhukhuleka kwemishini.”

Ezinye izinhlelo zokusebenza ezibalulekile zifaka phakathi imishini yokulinganisa eqondile kakhulu (ama-CMM), ukupakisha ama-microelectronics, kanye namathuluzi ocwaningo lwesayensi athuthukile—zonke izindawo lapho inhlanganisela eyingqayizivele yesikhulumi yokunemba, ukuzinza, kanye nomthamo womthwalo ibhekana khona nemikhawulo yobuchwepheshe yesikhathi eside.

Ikusasa Lokukhiqiza Okunembe Kakhulu

Njengoba ukukhiqiza kuqhubeka nokuqhubekela phambili ekufinyeleleni ekuncipheni nasekusebenzeni okuphezulu, isidingo sezinhlelo zokubeka izinto ngokunemba okukhulu sizokhula kakhulu. Ipulatifomu ye-Precision Marble Three-Axis Gantry ayimeli nje ukuthuthuka okuqhubekayo kodwa noshintsho oluyisisekelo endleleni okufezwa ngayo ukunemba—ukusebenzisa izakhiwo zezinto zemvelo kanye nobunjiniyela obuthuthukisiwe kunokuthembela kuphela ezinhlelweni zokunciphisa ezisebenzayo eziyinkimbinkimbi.

Kubakhiqizi ababhekana nezinselele ze-Industry 4.0, le nkundla inikeza umbono ngekusasa lobunjiniyela bokunemba. Kuyikusasa lapho umugqa phakathi "kokunemba kwelabhorethri" kanye "nokukhiqizwa kwezimboni" uqhubeka ufiphala, okwenza kube nokusungula izinto ezintsha okuzobumba yonke into kusukela ku-electronics yesizukulwane esilandelayo kuya kumadivayisi ezokwelapha asindisa impilo.

Njengoba omunye umhlaziyi wemboni esho: “Ezweni lokukhiqiza ngokunemba, ukuzinza akusona nje isici—kuyisisekelo lapho kwakhiwe khona zonke ezinye izinto ezithuthukisiwe. Le nkundla ayigcini nje ngokuphakamisa izinga; iyayakha kabusha ngokuphelele.”

Isikhathi sokuthunyelwe: Okthoba-31-2025