Emkhakheni omkhulu wokukhiqiza okunembayo kanye nocwaningo lwesayensi olusezingeni eliphezulu, ukunemba kwesiteji esintantayo somoya omile esinamandla okulawula ukunyakaza okunembe kakhulu sithatha isikhundla esibalulekile, kanye nesibusiso sesisekelo segwadle, kodwa futhi sivumele ukusebenza kwayo njengamaphiko engwe, ukudlala indima emikhakheni eminingi.

Ukukhiqizwa kwe-semiconductor: isiqinisekiso esiyinhloko sokunemba kwe-chip

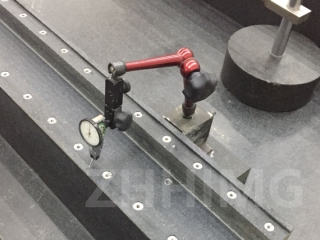

Ukwenziwa kwe-chip ye-semiconductor kubizwa ngokuthi "igugu lomqhele" lobuchwepheshe besimanje, futhi izidingo zokunemba zenqubo ngayinye zifinyelele izinga elicishe libe nzima. Esigabeni se-photolithography, iphethini yesiyingi ku-chip idinga ukudluliselwa endaweni eyiwafa ngokunemba kwe-nanometer. Iplathifomu ye-Precision static air float enesisekelo esinembayo, inganikeza ukusekela okuzinzile nokulawula ukunyakaza okunembile. Ukuzinza okuhle kakhulu kwesisekelo se-granite kuvikela ngempumelelo ukuphazamiseka kokudlidliza kwangaphandle, futhi i-coefficient yayo enwetshiwe ephansi iqinisekisa ukuzinza kobukhulu lapho izinga lokushisa lishintshashintsha, ukuze ukunemba kokuma kwe-wafer kufinyelele kuma-nanometers. Lokhu kubekwa okunembile kunikeza isisekelo esiqinile semishini ye-lithography ukuze kudwetshwe amaphethini wesifunda ngokunembile, kuthuthukise kakhulu ukuhlanganiswa kwe-chip kanye nesivuno, ukusiza imboni ye-semiconductor ukuthi iqhubeke nokudlula umkhawulo wenqubo, idale ama-chips anamandla, amancane, asetshenziswa kabanzi kumafoni ahlakaniphile, amakhompyutha, ubuhlakani bokwenziwa neminye imikhakha, futhi akhuthaze ukuthuthukiswa okuqhubekayo kwemishini kagesi ukuze ibe mncane futhi isebenze kakhulu.

Ukukhiqiza okunembayo okunembayo: Ukubaza itshe legumbi lombono ocacile

Ukwenziwa kwamalensi okubona, amalensi nezinye izakhi kudinga ukunemba okuphezulu kakhulu kwendawo kanye nokunemba komumo, futhi noma yikuphi ukukhubazeka okuncane kungase kuthinte ikhwalithi ye-optical imaging. Isisekelo sokunemba somoya we-Precision static air float float granite sidlala indima ebalulekile kulo mkhakha. Phakathi nenqubo yokugaya ilensi, inkundla ingashayela ithuluzi lokugaya ukuze kucutshungulwe indawo engaphezulu yelensi ngokunemba kwe-micron noma ngisho ne-sub-micron, iqinisekisa ukuthi ukucaba kwendawo kwelensi kuhlangabezana nezidingo zokuklama. Ukuzinza okuphezulu kwesisekelo se-granite kuqinisekisa ukunemba kokuma okuhlobene kwelensi kanye nethuluzi lokugaya phakathi nenqubo yomshini, ukugwema amaphutha omshini abangelwa ukudlidliza noma ukususwa. Enqubweni yokupholisha, ukusekelwa kwayo okuzinzile kuvumela imishini yokupholisha ukuthi isebenzise amandla afanayo, idale incazelo ephezulu, ama-lens optical aberration aphansi. Lawa ma-lens ekhwalithi ephezulu asetshenziswa kakhulu emishinini yezithombe esezingeni eliphezulu, izibonakhulu zezokwelapha, izibonakude zezinkanyezi nezinye izinsimbi zokubona, ezethula umhlaba ocacile futhi ontekenteke kakhudlwana kubantu, kodwa futhi ahlinzeke ngezingxenye eziyinhloko zamehlo zokuxilongwa kwezokwelapha, ukubhekwa kwezulu kanye nomunye umsebenzi wocwaningo lwesayensi, okusiza ukuhlola imfihlakalo yezwe elincane nelikhulu.

Ukwenziwa kwe-Aerospace: Ukusekelwa okuqinile kokusebenza kwendiza

Ukwenziwa kwe-Aerospace kuhlobene nokuvikeleka kwezwe namandla esayensi nobuchwepheshe, futhi ukunemba kwezingxenye kuqine kakhulu. Isisekelo se-granite esinembayo seplathifomu entantayo yomoya oqinile we-static ibalulekile ekwenziweni komshini weblade yenjini yomoya kanye nokwakhiwa kwezingxenye zesakhiwo sendiza. Lapho wenza ama-blade enjini ye-aero, kuyadingeka ukulawula ngokunembile indlela yamathuluzi ukuze uqiniseke ukuthi ukunemba kwephrofayili ye-blade kuhlangabezana nezinga lokuklama, elithinta ngqo ukusebenza kahle komlilo kanye nokudonsa kwenjini. Isiteji esintantayo somoya oqinile oqondile esisekelwe isisekelo sokunemba se-granite singakwazi ukubona ukulawulwa kokunyakaza okunembe kakhulu, ukuze ithuluzi likwazi ukusika ngokunembile into ye-blade futhi liqinisekise ikhwalithi yensingo. Ekwenziweni kwezingxenye zesakhiwo sendiza, kungakhathaliseki ukuthi ukubhola, ukugaywa noma ukuhlanganisa, ukuma okunemba okuphezulu nokunyakaza okuzinzile kweplatifomu kuqinisekisa ukunemba kobukhulu nokunemba kokuhlangana kwezingxenye zesakhiwo, kuthuthukise amandla esakhiwo ngenkathi kunciphisa isisindo sendiza, ukuthuthukisa ukuphepha nokusebenza kwendiza, futhi inikeza isiqinisekiso esiqinile sokuthuthukiswa kwe-erospace. Ukugqugquzela ukuhlola kwesintu isibhakabhaka nendawo yonke.

Ucwaningo lwe-biomedical: isandla sokunene sokuhlola izimfihlakalo zokuphila

Emkhakheni wocwaningo lwe-biomedical, ukusebenza okunembayo nokubhekwa kwamasampula amancane kuyisihluthulelo sokuvula imfihlakalo yokuphila nokunqoba izifo ezinzima. I-Precision static air float yesikhulumi somoya esinesisekelo esinembayo esinembayo sidlala indima ebalulekile ekulandelaneni kwezakhi zofuzo, ukukhohlisa kweseli nokunye. Emishinini yokulandelanisa izakhi zofuzo, inkundla ingahambisa ngokunembile isilayidi sesampula, ukuze ithuluzi lokulandelanisa likwazi ukufunda ngokunembile ulwazi lofuzo, lithuthukise ukunemba nokusebenza kahle kokulandelana kofuzo, futhi linikeze ukusekela okuqinile kokuxilongwa kofuzo kanye nokwelashwa komuntu siqu kwezifo. Ekwenziweni kwamangqamuzana amancane, ama-opharetha asebenzisa inkundla ukulawula ngokunembile ama-microneedles, ama-microstraws namanye amathuluzi ukuze ajove futhi akhiphe amangqamuzana ngamanye, enze ucwaningo oluseqophelweni eliphezulu olufana ne-cell biology kanye nokwelapha ngofuzo, ukuhlinzeka ngosekelo olubalulekile lwezobuchwepheshe lokuqanjwa kabusha nokuthuthukiswa kobuchwepheshe be-biomedical, nokuletha ithemba elisha empilweni yomuntu.

Ngokunemba kwayo okuhle kakhulu, ukuzinza nokuqina, isisekelo se-granite esinembayo sesiteji sokuntanta komoya esinembayo sesiphenduke amandla ayisisekelo okusekela izindawo eziningi ezinezidingo zokunemba okuphezulu, futhi siyaqhubeka nokukhuthaza ukuthuthukiswa kwezimboni ezihlukahlukene ngendlela eyinkimbinkimbi, ukufaka umfutho oqinile wenqubekelaphambili yesayensi nezobuchwepheshe kanye nokuthuthukiswa komphakathi.

Isikhathi sokuthumela: Apr-10-2025