Ekukhiqizeni ngokunemba, ekuhlolweni kocwaningo lwesayensi kanye nezinye izidingo zokunemba zensimu, ipulatifomu yokuntanta yomoya oqinile oqondile idlala indima ebalulekile. Ukukhetha isisekelo sepulatifomu, njengokubeka itshe legumbi lesakhiwo, kuhlobene ngqo nokusebenza kwepulatifomu. Isisekelo sokunemba kwe-granite kanye nesisekelo sokubumba amaminerali njengezinketho ezimbili ezidumile, ngayinye inezinzuzo zayo, okulandelayo ukuqhathanisa okuningiliziwe ngawe.

Ukuzinza: Umehluko phakathi kokwakheka kwekristalu yemvelo kanye nokuhlanganiswa okwenziwe

Isisekelo sokunemba kwe-granite ngemuva kwezigidi zeminyaka yezinguquko ze-geological, i-quartz yangaphakathi, i-feldspar kanye nezinye izimbiwa ziqinile, isakhiwo siminyene kakhulu futhi sifana. Uma sibhekene nokuphazamiseka kwangaphandle, njengokudlidliza okubangelwa ukusebenza kwemishini emikhulu ezungezile, isisekelo se-granite sifana nesivikelo esiqinile, esingavimba futhi sinciphise ngempumelelo, futhi singanciphisa ubukhulu bokudlidliza bepulatifomu yomoya ocindezelayo oqondile ngaphezu kuka-80%, sinikeze isisekelo esiqinile nesizinzile sokunyakaza okunembile kwepulatifomu. Eshabhu lokukhiqiza ama-chip e-semiconductor, inqubo ye-lithography inezidingo eziphezulu zokuzinza kwepulatifomu, kanti isisekelo se-granite siqinisekisa ukusebenza okunembile kwemishini ye-chip lithography, kusiza ukuqoshwa okunembile kwephethini yama-chip, futhi sithuthukisa kakhulu isivuno sokukhiqiza ama-chip.

Isisekelo sokubumba amaminerali senziwe ngezinhlayiya zamaminerali ezixutshwe ne-binder ekhethekile. Isakhiwo saso sangaphakathi sifana futhi sinezici ezithile zokudambisa ukudlidliza. Uma sibhekene nokudlidliza okuvamile, singanikeza indawo yokusebenza ezinzile yesikhulumi. Kodwa-ke, uma sibhekene nokuqina okuphezulu nokudlidliza okuqhubekayo, ikhono lokunciphisa ukudlidliza kwesisekelo sokubumba amaminerali alanele kancane uma kuqhathaniswa nesisekelo se-granite, okungaholela ekuphambukeni okuncane kokunyakaza kwepulatifomu futhi kuthinte ukunemba kokusebenza okunembile kakhulu.

Ukugcinwa kokunemba: ibhalansi yezinzuzo zemvelo kanye nokulawulwa kokwenziwa kokunwebeka okuphansi

I-Granite yaziwa ngokulingana kwayo okuphansi kakhulu kokukhula kokushisa, ngokuvamile okungu-5-7 × 10⁻⁶/℃. Endaweni yokushisa okushintshashintshayo, usayizi wesisekelo sokunemba se-granite awushintshi kakhulu. Emkhakheni wezinkanyezi, ipulatifomu yokuntanta yomoya ocindezelekile oqondile wokulungiswa kahle kwelensi yethelesikopu ihambisana nesisekelo se-granite, noma ngabe umehluko wokushisa phakathi kwemini nobusuku ubalulekile, ingaqinisekisa ukuthi ukunemba kokubekwa kwelensi kugcinwa ezingeni le-submicron, kusize izazi zezinkanyezi ukuthi zibambe izinguquko ezincane zezidalwa zasezulwini ezikude.

Ekwakhiweni kwezinto zokwenziwa kwezinto zokubumba amaminerali, izici zokukhula kokushisa zingalungiswa futhi zilawulwe, futhi i-coefficient yokukhula kokushisa ingaba seduze noma ingcono kune-granite ngokulungisa isilinganiso samaminerali nama-binder. Kweminye imishini yokulinganisa ezwela izinga lokushisa, enembile kakhulu, isisekelo se-mineral cast singagcina usayizi ozinzile lapho izinga lokushisa lishintsha, okuqinisekisa ukunemba kokunyakaza kwepulatifomu. Kodwa-ke, isisekelo sokubumba amaminerali sithinteka yizici ezifana nokuguga kwe-binder, futhi ukuzinza kokunemba kwesikhathi eside kudinga ukubonwa kabanzi.

Ukuqina: Izici zokuqina okuphezulu kwetshe lemvelo kanye nezinto ezihlanganisiwe ezingakhathali

Ubulukhuni begranite buphakeme, ubulukhuni be-Mohs bungafinyelela ku-6-7, ngokumelana okuhle nokuguguleka. Elabhorethri yesayensi yezinto zokwakha, ipulatifomu yomoya ontantayo ocindezelwe ngokunemba okuqinile esetshenziswa njalo, isisekelo sayo segranite singamelana ngempumelelo nokulahlekelwa ukungqubuzana kwesikhathi eside, uma kuqhathaniswa nesisekelo esivamile, singandisa umjikelezo wokugcinwa kwepulatifomu ngaphezu kuka-50%, sinciphise izindleko zokugcinwa kwemishini, futhi siqinisekise ukuqhubeka komsebenzi wocwaningo lwesayensi. Kodwa-ke, izinto zegranite ziyaphuka futhi kulula ukuziphula uma zithinteka ngengozi.

Isisekelo sokuphonswa kwamaminerali sinezici ezinhle kakhulu zokulwa nokukhathala, ezingamelana ngempumelelo nomonakalo wokukhathala futhi zigcine ubuqotho besakhiwo ngesikhathi sokunyakaza okuphindaphindwayo kwesikhathi eside kwepulatifomu yokuntanta yomoya ocindezelwe ngokunemba. Ngesikhathi esifanayo, sinokumelana okuthile namakhemikhali ajwayelekile, futhi endaweni enengozi encane yokugqwala kwamakhemikhali, ihlala isikhathi eside kunesisekelo se-granite. Kodwa-ke, ezindaweni ezimbi kakhulu njengomswakama ophezulu, i-binder esisekelweni se-mineral cast ingathinteka, kunciphisa ukuqina kwayo.

Izindleko zokukhiqiza kanye nobunzima bokucubungula: Izinselele zamatshe emvelo kanye nemikhawulo yokubumba okwenziwe

Ukumbiwa nokuthuthwa kwezinto zokusetshenziswa ze-granite kuyinkimbinkimbi, futhi ukucubungula kudinga imishini nobuchwepheshe obuphezulu kakhulu. Ngenxa yobulukhuni bayo obukhulu kanye nokuqhekeka, kulula ukuba nezinkinga ezifana nokuwa komphetho kanye nokuqhekeka ekusikeni, ekugayeni, ekupholisheni nakwezinye izinqubo, futhi izinga lokulahla izinto ezilahliwe liphezulu kakhulu, okuholela ezindleleni zokukhiqiza eziphezulu.

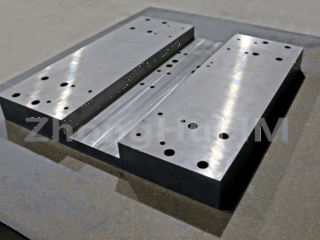

Ukukhiqizwa kwesisekelo sokuphonswa kwamaminerali kudinga isikhunta nenqubo ethile, futhi izindleko zokuqala zokuthuthukiswa kwesikhunta ziphakeme, kodwa uma isikhunta sesibunjiwe, ukukhiqizwa ngobuningi kungafinyelelwa futhi izindleko zeyunithi zingancishiswa. Inqubo yayo yokucubungula ilula kakhulu uma iqhathaniswa ne-granite, futhi ingafinyelela izidingo zokunemba okuphezulu ngezindlela zokucubungula ngomshini, futhi inamandla okusebenzisa imali kahle ezimweni zokusetshenziswa ezinkulu.

Isikhathi sokuthunyelwe: Ephreli-10-2025