Emkhakheni wokuhlolwa kwe-semiconductor, ukukhethwa kwezinto zeplatifomu yokuhlola kudlala indima ebalulekile ekunembileni kokuhlola kanye nokuqina kwemishini. Uma kuqhathaniswa nezinto zensimbi ezivamile, i-granite iba ukukhetha okuhle kakhulu kwamapulatifomu okuhlola i-semiconductor ngenxa yokusebenza kwayo okuvelele.

Ukumelana nokugqwala okuvelele kuqinisekisa ukusebenza okuzinzile kwesikhathi eside

Ngesikhathi senqubo yokuhlola i-semiconductor, kuvame ukuhileleka ama-reagents ahlukahlukene amakhemikhali, njengesisombululo se-potassium hydroxide (KOH) esisetshenziselwa ukuthuthukiswa kwe-photoresist, kanye nezinto ezibola kakhulu njenge-hydrofluoric acid (HF) kanye ne-nitric acid (HNO₃) enqubweni yokuqopha. Insimbi ecijile yakhiwe kakhulu yizinto zensimbi. Endaweni enjalo yamakhemikhali, ukusabela kokunciphisa i-oxidation kungenzeka kakhulu. Ama-athomu ensimbi alahlekelwa ama-electron futhi abhekane nokusabela kokufuduka nezinto ezine-acidic esixazululweni, okubangela ukugqwala okusheshayo kobuso, kwakha ukugqwala nokuncipha, futhi kulimaze ukunemba okuthe tyaba kanye nobukhulu bepulatifomu.

Ngokuphambene nalokho, ukwakheka kwamaminerali egranite kuyinika ukumelana nokugqwala okungavamile. Ingxenye yayo eyinhloko, i-quartz (SiO₂), inezakhiwo zamakhemikhali ezizinzile kakhulu futhi ayisebenzi kahle nama-acid avamile kanye nezisekelo. Amaminerali afana ne-feldspar nawo awasebenzi ezindaweni zamakhemikhali ezijwayelekile. Inani elikhulu lokuhlola likhombisile ukuthi endaweni efanayo yamakhemikhali okutholwa kwe-semiconductor, ukumelana nokugqwala kwamakhemikhali egranite kuphakeme ngokuphindwe izikhathi ezingu-15 kunokwensimbi ephonswe. Lokhu kusho ukuthi ukusebenzisa amapulatifomu egranite kunganciphisa kakhulu imvamisa kanye nezindleko zokugcinwa kwemishini okubangelwa ukugqwala, kwandise impilo yenkonzo yemishini, futhi kuqinisekise ukuzinza kwesikhathi eside kokunemba kokutholwa.

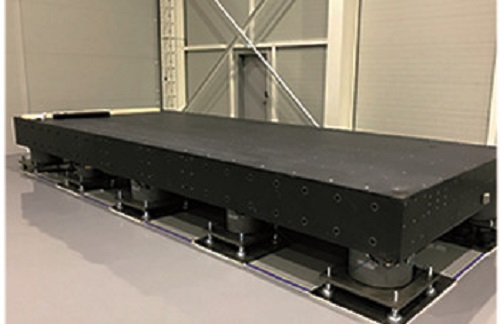

Ukuzinza okuphezulu kakhulu, okuhlangabezana nezidingo zokunemba kokutholwa kwezinga le-nanometer

Ukuhlolwa kwe-semiconductor kunezidingo eziphakeme kakhulu zokuqina kwepulatifomu futhi kudinga ukulinganisa ngokunembile izici ze-chip ku-nanoscale. I-coefficient yokwanda kokushisa kwensimbi ephonswe iphakeme kakhulu, cishe i-10-12 × 10⁻⁶/℃. Ukushisa okukhiqizwa ukusebenza kwemishini yokuthola noma ukuguquguquka kwezinga lokushisa elizungezile kuzobangela ukwanda okukhulu kokushisa kanye nokufinyela kwepulatifomu yensimbi ephonswe, okuholela ekuphambukeni kwesimo phakathi kweprobe yokuthola kanye ne-chip futhi kuthinte ukunemba kokulinganisa.

I-coefficient yokwanda kokushisa kwe-granite ingu-0.6-5×10⁻⁶/℃ kuphela, okuyingxenyana noma ngaphansi kakhulu kweyensimbi ephonswe. Isakhiwo sayo siminyene. Ukucindezeleka kwangaphakathi kuye kwasuswa ngokuyisisekelo ngokuguga kwemvelo kwesikhathi eside futhi kuthinteka kancane yizinguquko zokushisa. Ngaphezu kwalokho, i-granite inokuqina okuqinile, enobunzima obuphindwe kabili kuya kathathu kunobensimbi ephonswe (okulingana ne-HRC > 51), engamelana ngempumelelo nemiphumela yangaphandle nokudlidliza futhi igcine ukuthamba nokuqondile kwepulatifomu. Isibonelo, ekutholakaleni kwesekethe ye-chip enembile kakhulu, ipulatifomu ye-granite ingalawula iphutha lokuthamba ngaphakathi kuka-±0.5μm/m, iqinisekise ukuthi imishini yokuthola isakwazi ukuthola ukunemba kwe-nanoscale ezindaweni eziyinkimbinkimbi.

Impahla evelele yokulwa nogesi, edala indawo yokuthola ehlanzekile

Izingxenye ze-elekthronikhi kanye nezinzwa emishinini yokuhlola ye-semiconductor zizwela kakhulu ekuphazamisekeni kwe-electromagnetic. Insimbi ecijile inezinga elithile lemagnetism. Endaweni ye-electromagnetic, izokhiqiza insimu yamagnetic ebangelwayo, ezophazamisa izimpawu ze-electromagnetic zemishini yokuthola, okuholela ekuphazamisekeni kwesignali kanye nedatha yokuthola engajwayelekile.

Ngakolunye uhlangothi, i-granite iyinto elwa nomagnetic futhi ayihlukaniswa neze yizinkundla zamagnetic zangaphandle. Ama-electron angaphakathi akhona ngamabili ngaphakathi kwezibopho zamakhemikhali, futhi isakhiwo sizinzile, asithinteki amandla angaphandle kagesi. Endaweni enamandla kagesi kagesi engu-10mT, amandla kagesi kagesi abangelwa ebusweni be-granite angaphansi kuka-0.001mT, kuyilapho lawo aphezu kwensimbi ephonswe phezulu engaphezu kuka-8mT. Lesi sici senza ipulatifomu ye-granite ikwazi ukudala indawo ehlanzekile kagesi kagesi yemishini yokuthola, efanelekile kakhulu ezimweni ezinezidingo eziqinile zomsindo kagesi kagesi njengokutholwa kwe-quantum chip kanye nokutholwa kwesekethe ye-analog enembile kakhulu, okuthuthukisa ngempumelelo ukuthembeka kanye nokuvumelana kwemiphumela yokuthola.

Ekwakhiweni kwamapulatifomu okuhlola ama-semiconductor, i-granite idlule ngokuphelele izinto zensimbi ezicijile ngenxa yezinzuzo zayo ezibalulekile njengokumelana nokugqwala, ukuzinza kanye nokulwa nomagnetism. Njengoba ubuchwepheshe be-semiconductor buqhubekela phambili ekuqondeni okuphezulu, i-granite izodlala indima ebaluleke kakhulu ekuqinisekiseni ukusebenza kwemishini yokuhlola kanye nokukhuthaza intuthuko yemboni ye-semiconductor.

Isikhathi sokuthunyelwe: Meyi-15-2025