Emngceleni wokukhiqiza ngokunemba kanye nocwaningo lwesayensi, isidingo sokulawula ukunyakaza ngokunemba okukhulu siyakhula usuku nosuku. Njengemishini ebalulekile yokufeza ukunyakaza okuqondile okuphezulu, ukusebenza kwemoduli entantayo yomoya ene-axis eyodwa eqondile kakhulu kuthinta ngqo ikhwalithi yomkhiqizo wokugcina kanye nokunemba kwemiphumela yocwaningo lwesayensi. Phakathi kwezici eziningi ezithonyayo, ukusetshenziswa kwesisekelo se-granite kuyinika inzuzo engenakuqhathaniswa futhi iba yinto eyinhloko yokuqinisekisa ukunemba okuhle kakhulu.

I-Granite, ngemva kwezigidi zeminyaka yezinguquko ze-geological, isakhiwo sangaphakathi siminyene kakhulu futhi sifana. Yakhiwe kakhulu nge-quartz, i-feldspar kanye nezinye izimbiwa, lokhu kwakheka kwezinto eziyingqayizivele kunikeza i-granite izakhiwo ezinhle kakhulu zomzimba. Uma isetshenziswa njengesisekelo se-single axis air float ultra-precision module, i-granite iqala ibonise ukuzinza okuphezulu kakhulu. Uma kuqhathaniswa nezisekelo zezinto zensimbi ezivamile, izisekelo ze-granite zibonisa ukumelana okunamandla kokuguquguquka lapho kubhekene nokuphazamiseka kwemvelo kwangaphandle, njengokushintshashintsha kwezinga lokushisa kanye nokudlidliza komshini. Enkambisweni yokukhiqizwa kwe-chip electronic, ukunemba kokubeka kwe-chip lithography kuyadingeka ukuze kufinyelelwe ezingeni le-nanometer. Esitolo sokukhiqiza, ukudlidliza okubangelwa ukusebenza kwemishini emikhulu kanye nezinguquko ezincane ekushiseni okuzungezile kungathinta ukunemba kokunyakaza kwemishini ye-lithography. I-single axis air floating ultra-precision motion module enesisekelo se-granite inganciphisa ngempumelelo ukudlidliza kwangaphandle futhi inciphise i-amplitude yokudlidliza edluliselwa kwi-module yokunyakaza ngaphezu kwama-80%. Ngesikhathi esifanayo, i-coefficient yayo ephansi kakhulu yokwanda kokushisa yenza usayizi wesisekelo ushintshe kancane kakhulu lapho izinga lokushisa lishintsha, okuqinisekisa ukuthi imoduli yokunyakaza entantayo emoyeni isengakwazi ukugcina ukunemba kokunyakaza okuzinzile endaweni eyinkimbinkimbi, ihlinzeka ngesisekelo sokuma esinembile se-chip lithography, futhi ithuthukisa kakhulu isivuno sokukhiqizwa kwama-chip.

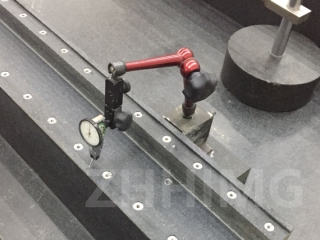

Ngaphezu kwalokho, i-granite inokumelana okuhle nokuguguleka. Enkambisweni yokunyakaza okuphindaphindiwe okuphindaphindayo kwe-module ye-single-axis air float module enembile kakhulu, yize kukhona ukwesekwa kwefilimu yegesi phakathi kwe-air float slider kanye nesisekelo, ukusetshenziswa kwesikhathi eside kuzokhiqiza izinga elithile lokuguguleka. Isisekelo se-granite, esinezici zaso zobulukhuni obuphezulu, singamelana ngempumelelo nokuguguleka okubangelwa yilokhu kuguguleka futhi sandise impilo yesevisi ye-module yokunyakaza. Elabhorethri yocwaningo lwesayensi yamanyuvesi, imishini yokuhlola esetshenziselwa ukuthola izinhlayiya ezincane idinga i-module yokunyakaza enembile kakhulu yokuguguleka komoya kwe-uniaxial ukuze isebenze kahle isikhathi eside ukuthola inani elikhulu ledatha yokuhlola enembile. Ukumelana nokuguguleka okuphezulu kwesisekelo se-granite kuqinisekisa ukuthi ukunemba kwe-motion module kusengakwazi ukugcinwa ezingeni lokuqala lokunemba okuphezulu ngemva kwesikhathi eside sokusetshenziswa, okunikeza isiqinisekiso esithembekile sokuqhubeka nokunemba komsebenzi wocwaningo lwesayensi, nokusiza abacwaningi ukuthi bahlole ngokujulile imfihlakalo yomhlaba we-microscopic.

Imojula yokunyakaza kwe-single axis air float enesisekelo se-granite ifana "ne-navigator" enembile yokukhiqiza ngokunemba kanye nocwaningo lwesayensi. Isisekelo se-granite ngokuqina kwayo okuhle kakhulu, ukumelana nokuguguleka, kokunyakaza okunembile kwemojula yokunyakaza kwe-air floating inikeza ukwesekwa okuqinile, ekukhiqizeni i-semiconductor, ekukhiqizeni izinsimbi ezibonakalayo, ocwaningweni lwesayensi olusezingeni eliphezulu kanye nezinye izidingo eziningi zokunemba zensimu, idlala indima ebalulekile engenakuphikwa, ikhuthaza imboni ekuqondeni okuphezulu, isiqondiso sekhwalithi ephezulu.

Isikhathi sokuthunyelwe: Ephreli-07-2025