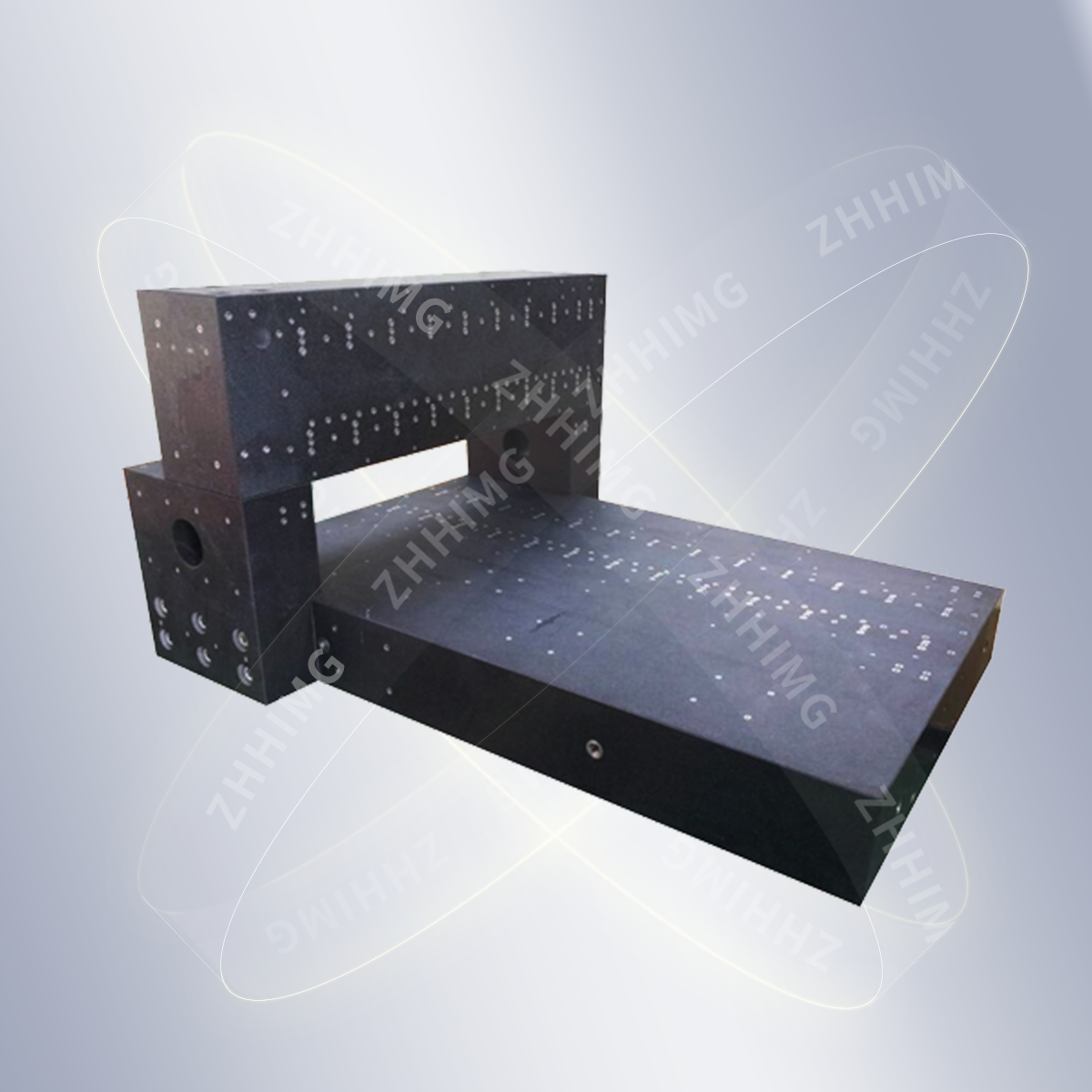

Emkhakheni wokulinganisa ngokunemba, ukunemba kokulinganisa komshini wokulinganisa onama-three-coordinate (CMM) kuthinta ngqo ukuthembeka kwemiphumela yokulinganisa. Ama-granite rulers anokunemba okungu-1μm, ngenxa yezakhiwo zawo zomzimba ezizinzile kanye nokunemba okuphezulu kakhulu kokukhiqiza, abe ngamathuluzi afanele okulinganisa imishini yokulinganisa onama-three-coordinate. Okulandelayo kuzokunikeza isingeniso esiningiliziwe ezinyathelweni ezithile zokulinganisa umshini wokulinganisa onama-three-coordinate usebenzisa i-ZHHIMG® 1μm precision granite rule.

I. Amalungiselelo ngaphambi kokulinganisa

Hlola izimo zemvelo: Qinisekisa ukuthi izinga lokushisa lendawo yokulinganisa lizinzile ku-20±1℃, futhi umswakama ulawulwa phakathi kuka-40% no-60%. Ngesikhathi esifanayo, nciphisa ukuphazamiseka kokudlidliza okubangelwa ukunyakaza kwabasebenzi kanye nokusebenza kwemishini. Izindinganiso zemvelo ze-workshop zokushisa nomswakama eziqhubekayo ze-ZHHIMG® zenzelwe ngqo ukuqinisekisa ukuthi imikhiqizo ye-granite ayithintwa yizici zemvelo ngesikhathi senqubo yokukhiqiza. Lokhu futhi kufakazela ngokungaqondile ukubaluleka kwezimo zemvelo zokulinganisa okunembile.

Imishini yokuhlanza namathuluzi: Sebenzisa indwangu engena-lint kanye nesihlanzi esikhethekile ukuze usule ngokucophelela itafula lokusebenza, i-probe kanye nobuso bombusi we-granite womshini wokulinganisa onezinhlanganisela ezintathu ukuqinisekisa ukuthi akukho uthuli, amabala kawoyela noma okunye ukungcola, ukuze kungathinti ukunemba kokulinganisa.

Qinisekisa isitifiketi nesimo: Qinisekisa ukuthi isitifiketi sokulinganisa esinamathiselwe ku-granite ruler singaphakathi kwesikhathi saso sokusebenza, futhi akukho mihuzuko esobala, umonakalo noma ezinye iziphambeko ebusweni bo-ruler. Yonke imikhiqizo ye-ZHHIMG® ihlolwa ngokuqinile futhi ifakwe izitifiketi zokuhlola ezigunyaziwe ukuqinisekisa ukuthi ukunemba komkhiqizo kuhlangabezana nezindinganiso.

Ii. Izinyathelo Zokusebenza Zokulinganisa

Beka irula legranite: Beka irula legranite eliqondile elingu-1μm kancane kancane etafuleni lokusebenza lomshini wokulinganisa onezikhonkwane ezintathu, bese uzama ukulenza lihambisane nezikhonkwane ze-coordinate zomshini wokulinganisa. Sebenzisa i-fixture ekhethekile noma isisekelo sikamazibuthe ukuze ulilungise ukuze uvimbele irula ukuthi linganyakazi ngesikhathi senqubo yokulinganisa.

Ukuqaliswa kwe-probe kanye nokubekwa kwayo: Qala umshini wokulinganisa onezinhlanganisela ezintathu bese wenza imisebenzi yokuqalisa ku-probe ukuqinisekisa ukuthi isesimweni sokusebenza esijwayelekile. Bese, lawula ikhanda lokulinganisa lomshini wokulinganisa ukuze uhambe kancane ngaphezu kwendawo yokuqala yokulinganisa yerula le-granite, ulungiselela ukulinganisa.

Thatha inani elimaphakathi lokulinganisa amaphuzu amaningi: Ngokuqondene nobude bomlawuli we-granite, khetha ngokulinganayo okungenani amaphuzu okulinganisa amahlanu (njengendawo yokuqala, iphuzu elingu-1/4, iphuzu eliphakathi, iphuzu elingu-3/4, kanye nephuzu lokugcina), lawula i-probe ukuze wenze isilinganiso sokuxhumana endaweni ngayinye yokulinganisa ngokulandelana, bese uqopha idatha yokulinganisa yephuzu ngalinye. Ukunemba okuphezulu kwe-ZHHIMG® granite straightedges kungaqinisekisa ukuthi le datha yokulinganisa ibonisa ngempela isimo sokunemba komshini wokulinganisa.

Ukubalwa kwamaphutha nokulinganiswa: Qhathanisa idatha eqoshwe umshini wokulinganisa nenani elijwayelekile lombusi we-granite ukuze kubalwe inani lamaphutha lephuzu ngalinye lokulinganisa. Ngokwesimo samaphutha, uhlelo lokuhlanganisa lomshini wokulinganisa onezinhlanganisela ezintathu luyalungiswa futhi lulinganiswe ngokufanele ngokusebenzisa isofthiwe yokulinganisa yomshini wokulinganisa onezinhlanganisela ezintathu kuze kube yilapho iphutha lokulinganisa lilawulwa ngaphakathi kobubanzi obuvunyelwe.

Ukuqinisekiswa kokulinganisa okuphindaphindiwe: Ngemva kokuthi ukulinganisa sekuqediwe, yenza izilinganiso zamaphuzu amaningi ku-granite ruler futhi ukuqinisekisa umphumela wokulinganisa. Uma iphutha phakathi komphumela wokulinganisa kanye nenani elijwayelekile lingaphakathi kuka-±1μm, libonisa ukuthi ukulinganisa kuphumelele. Uma iphutha likhulu kakhulu, izinyathelo zokusebenza zidinga ukuhlolwa kabusha. Uma kudingeka, xhumana nochwepheshe ukuze baphathe.

Iii. Ukugcinwa kanye Nezinyathelo Zokuqapha Ngemva Kokulinganisa

Gcina kahle irula: Ngemva kokuba umsebenzi wokulinganisa usuqediwe, sula irula legranite ngendwangu ehlanzekile engenalo ulwelwesi, ulibeke ebhokisini lokupakisha elikhethekile noma ebhokisini elivikelayo, bese uligcina endaweni eyomile neyokushisa okuhlala njalo ukuvimbela irula ukuthi lingamanzi noma lonakale.

Ukulinganisa okuvamile: Ukuze kuqinisekiswe ukunemba kokulinganisa kwesikhathi eside komshini wokulinganisa, kunconywa ukuthi kulinganiswe umshini wokulinganisa onezinhlanganisela ezintathu ngombusi we-granite oqondile ongu-1μm njalo ezinyangeni ezi-3 kuya kwezi-6. Ngesikhathi esifanayo, lapho umshini wokulinganisa usuhambile, walungiswa noma washintsha kakhulu izimo zemvelo, ukulinganisa kufanele kwenziwe ngesikhathi esifanele.

Ukusebenza okujwayelekile: Ngesikhathi sokusetshenziswa kwansuku zonke, landela ngokuqinile izinqubo zokusebenza ukuze usebenzise umshini wokulinganisa onezinhlanganisela ezintathu kanye ne-granite ruler ukuze ugweme ukulimala kwemishini noma amathuluzi ngenxa yokusebenza okungafanele, okungathinta ukunemba kokulinganisa.

Ngezinyathelo ezingenhla, i-ZHHIMG® 1μm precision granite ruler ingasetshenziswa ngempumelelo ukulinganisa umshini wokulinganisa onezinhlanganisela ezintathu, ukuqinisekisa ukunemba nokuthembeka kwemiphumela yawo yokulinganisa kanye nokunikeza isiqinisekiso esinamandla somsebenzi wokulinganisa onembile.

Isikhathi sokuthunyelwe: Juni-18-2025