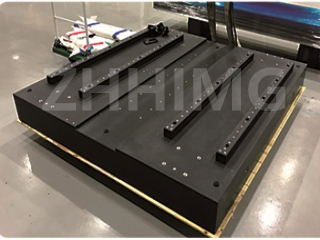

Embonini ye-semiconductor, ukuhlolwa kwe-wafer kuyisixhumanisi esibalulekile sokuqinisekisa ikhwalithi nokusebenza kwe-chip, futhi ukunemba nokuqina kwetafula lokuhlola kudlala indima ebalulekile emiphumeleni yokuthola. Isisekelo se-granite ngezici zaso ezihlukile, siba yisinqumo esifanele setafula lokuhlola i-wafer ye-semiconductor, okulandelayo okuvela ekuhlaziyweni okunezinhlangothi eziningi kuwe.

Okokuqala, ubukhulu besiqinisekiso sokunemba

1. Ukuthamba kanye nokuqondile okuphezulu kakhulu: Isisekelo se-granite sicutshungulwa ubuchwepheshe bokucubungula obuthuthukisiwe, futhi ukuthamba kungafinyelela ku-±0.001mm/m noma ukunemba okuphezulu nakakhulu, futhi ukuthamba nakho kuhle kakhulu. Enqubweni yokuhlola i-wafer, indiza enembile kakhulu inikeza ukwesekwa okuzinzile kwe-wafer futhi iqinisekisa ukuxhumana okunembile phakathi kwe-probe yemishini yokuhlola kanye namajoyinti e-solder ebusweni be-wafer.

2. I-coefficient ephansi kakhulu yokwanda kokushisa: ukukhiqizwa kwe-semiconductor kuyazwela ekushintsheni kwezinga lokushisa, futhi i-coefficient yokwanda kokushisa kwe-granite iphansi kakhulu, ngokuvamile cishe ngo-5×10⁻⁶/℃. Lapho ipulatifomu yokuthola isebenza, noma ngabe izinga lokushisa elizungezile liyashintshashintsha, usayizi wesisekelo se-granite awushintshi kakhulu. Isibonelo, endaweni yokusebenzela yokushisa okuphezulu ehlobo, izinga lokushisa lepulatifomu yokuthola isisekelo sensimbi evamile lingabangela ukuthi indawo ehlobene ye-wafer kanye nemishini yokuthola ishintshe, okuthinta ukunemba kokuthola; Ipulatifomu yokuthola isisekelo se-granite ingagcina ukuzinza, iqinisekise ukunemba kwendawo ehlobene ye-wafer kanye nemishini yokuthola ngesikhathi senqubo yokuthola, futhi inikeze indawo ezinzile yokuthola ukunemba okuphezulu.

Okwesibili, ubukhulu bokuzinza

1. Isakhiwo esizinzile kanye nokumelana nokudlidliza: I-Granite ngemva kwezigidi zeminyaka yezinqubo ze-geological, isakhiwo sangaphakathi siminyene futhi sifana. Endaweni eyinkimbinkimbi yefektri ye-semiconductor, ukudlidliza okubangelwa ukusebenza kwemishini yangaphandle kanye nabasebenzi abahambahambayo kuncishiswa ngempumelelo yisisekelo se-granite.

2. Ukunemba kokusetshenziswa kwesikhathi eside: uma kuqhathaniswa nezinye izinto, i-granite inobunzima obuphezulu, ukumelana nokuguguleka okunamandla, kanti ubunzima be-Mohs bungafinyelela ku-6-7. Ubuso besisekelo se-granite abugugi kalula ngesikhathi sokulayisha, ukulayisha nokuhlola i-wafer njalo. Ngokusho kokusetshenziswa kwangempela kwezibalo zedatha, ukusetshenziswa kwetafula lokuhlola isisekelo se-granite, ukusebenza okuqhubekayo ngemva kwamahora angu-5000, ukunemba kokusicaba nokuqondile kusengakwazi ukugcinwa ngaphezu kwama-98% wokunemba kokuqala, kunciphisa imishini ngenxa yokuguguleka kwesisekelo okubangelwa izikhathi zokulinganisa ezivamile kanye nokulungisa, kunciphisa izindleko zokusebenza kwebhizinisi, ukuqinisekisa ukuzinza kwesikhathi eside komsebenzi wokuhlola.

Okwesithathu, ubukhulu obuhlanzekile nobuphikisana nokuphazamiseka

1. Ukukhiqizwa kothuli oluphansi: indawo yokukhiqiza ye-semiconductor idinga ukuhlanzeka kakhulu, futhi izinto ze-granite ngokwazo zizinzile futhi akulula ukukhiqiza izinhlayiya zothuli. Ngesikhathi sokusebenza kwepulatifomu yokuhlola, uthuli olukhiqizwa yisisekelo luyagwenywa ukuze kungcoliswe i-wafer, futhi ingozi yesekethe esifushane kanye nesekethe evulekile ebangelwa izinhlayiya zothuli iyancishiswa. Endaweni yokuhlola i-wafer ye-workshop engenalo uthuli, ukugcwala kothuli oluzungeze itafula lokuhlola isisekelo se-granite kuhlala kulawulwa ezingeni eliphansi kakhulu, kuhlangatshezwane nezidingo zokuhlanzeka eziqinile zemboni ye-semiconductor.

2. Akukho ukuphazamiseka kwe-magnetic: imishini yokuthola ibucayi endaweni ye-electromagnetic, kanti i-granite iyinto engeyona i-magnetic, engeke iphazamise isignali ye-electronic yemishini yokuthola. Ekusetshenzisweni kokutholwa kwemisebe ye-electron kanye nobunye ubuchwepheshe bokuhlola obudinga indawo ephezulu kakhulu ye-electromagnetic, isisekelo se-granite siqinisekisa ukudluliswa okuzinzile kwesignali ye-electronic yemishini yokuthola futhi siqinisekisa ukunemba kwemiphumela yokuhlolwa. Isibonelo, lapho i-wafer ihlolwa ukusebenza kukagesi okunembe kakhulu, isisekelo se-granite esingeyona i-magnetic sigwema ukuphazamiseka kwesignali yamanje ne-voltage yokuthola, ukuze idatha yokuthola ibonise ngempela izici zikagesi ze-wafer.

Isikhathi sokuthunyelwe: Mashi-31-2025