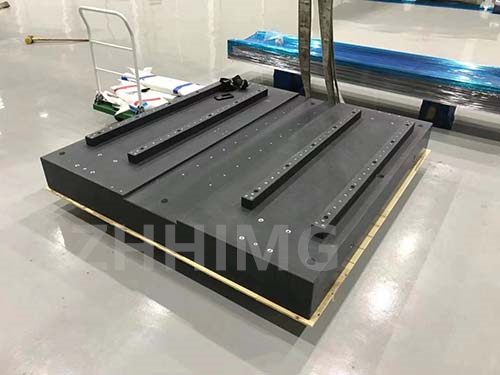

I-Industrial computed tomography (CT) isibe ithuluzi elibalulekile lokuhlola ikhwalithi, ubunjiniyela obubuyela emuva, i-metrology, kanye nocwaningo lwesayensi ezinhlobonhlobo zezimboni. Ukunemba, isivinini, kanye nokungonakalisi kwe-CT yezimboni kuncike ezintweni ezahlukahlukene, okuhlanganisa ukwakheka kanye nokukhiqizwa kwesisekelo somshini. I-Granite ingenye yezinto ezithandwa kakhulu zezisekelo zomshini we-CT ngenxa yezakhiwo zayo ezihlukile, njengokuqina, ukuqina, ukudambisa, ukuzinza kokushisa, kanye nokusebenza kahle komshini. Kulesi sihloko, sizoxoxa ngezinzuzo kanye nokungalungi kwezisekelo zomshini we-Granite ze-CT yezimboni.

Izinzuzo Zesisekelo Somshini We-Granite se-Industrial CT

1. Ukuzinza: I-Granite ine-coefficient ephansi yokwanda kokushisa, okusho ukuthi usayizi wayo nesimo sayo kuyafana ngaphansi kwamazinga okushisa ahlukene kanye namazinga omswakama. Lesi sici siqinisekisa ukuthi umshini we-CT uhlala uzinzile futhi unembile kulo lonke ukusebenza kwawo, ngaphandle kokuthintwa yizici zangaphandle njengokudlidliza, ukushaqeka, kanye nokuguquguquka. Imishini ye-CT ezinzile ibalulekile ekufinyeleleni imiphumela esezingeni eliphezulu nehambisanayo ezinhlelweni ezahlukahlukene, njengokutholwa kwamaphutha, ukulinganiswa kobukhulu, kanye nokuhlaziywa kwezinto.

2. Ukuqina: I-Granite ine-modulus ephezulu ye-Young, okusho ukuthi imelana nokuguquguquka ngaphansi kokucindezeleka noma umthwalo. Lesi sici siqinisekisa ukuthi isisekelo somshini we-CT sigcina ukuma nobukhulu baso, ngisho nangaphansi kwemithwalo esindayo noma ukushayisana. Imishini ye-CT eqinile ibalulekile ekunciphiseni amaphutha nokungaqiniseki ezithombeni noma kudatha ye-CT, ikakhulukazi ezinhlelweni zokusebenza ezinembe kakhulu njenge-micro-CT kanye ne-nano-CT.

3. Ukudambisa: I-Granite ine-coefficient ephezulu yokudambisa, okusho ukuthi imunca futhi ichithe amandla noma ukudlidliza. Lesi sici siqinisekisa ukuthi isisekelo somshini we-CT sinciphisa noma siqeda ukudlidliza noma imisindo ekhiqizwa yizingxenye zesistimu ye-CT, njenge-X-ray tube, ama-detector, kanye nezigaba. Imishini ye-CT edambisiwe ibalulekile ekuthuthukiseni isilinganiso sesiginali kuya kumsindo, ukunciphisa izinto ezisetshenzisiwe, kanye nokuthuthukisa ukulungiswa kwendawo kwezithombe noma idatha ye-CT.

4. Ukuqina Kokushisa: I-Granite inokushisa okuphezulu kanye ne-coefficient yokukhulisa ukushisa ephansi, okusho ukuthi ingahlakaza noma imunce ukushisa kahle ngaphandle kokushintsha usayizi noma ukuma kwayo kakhulu. Lesi sici siqinisekisa ukuthi isisekelo somshini we-CT sihlala sizinzile futhi sinembile ngisho nangaphansi kokujikeleza kokushisa noma izimo ze-gradient, njengasesikhathini sokuskena eside noma lapho kusetshenziswa ama-X-ray anamandla aphezulu.

5. Ukukwazi Ukulungisa Izinto: I-granite ingashintshwa ngomshini noma ipholishwe ngokunemba okuphezulu kanye namazinga okushelela, okusho ukuthi isisekelo somshini we-CT singenziwa ngezimo eziqondile, osayizi, kanye nokuqedwa kwendawo. Lesi sici siqinisekisa ukuthi isisekelo somshini we-CT sifanelana kahle nezinye izingxenye zohlelo lwe-CT, njenge-gantry, i-enclosure, kanye ne-shielding. Izisekelo zomshini we-CT ezingasetshenziswa zibalulekile ekunciphiseni amaphutha okuhlanganisa, ukuthuthukisa ukuphepha, kanye nokuthuthukisa ukusebenza okuphelele kohlelo lwe-CT.

Izinkinga Zokusebenzisa Isisekelo Somshini We-Granite Se-Industrial CT

1. Isisindo: I-Granite iyinto eqinile futhi esindayo, okusho ukuthi isisekelo somshini we-CT esenziwe nge-granite singaba nzima ukusithutha, ukusifaka, noma ukusithutha. Le ndawo ingadinga imishini ekhethekile yokuphatha, njengama-crane noma ama-hoist, ukuhambisa isisekelo somshini we-CT, okungakhuphula izindleko nesikhathi sokufakwa noma ukulungiswa kohlelo lwe-CT. Kodwa-ke, lokhu kungahle kuncishiswe ngokuklama isisekelo somshini we-CT ngezingxenye ezihlanganisiwe noma ezisuswayo, kanye nokwenza ngcono ukwakheka noma ukufinyeleleka kohlelo lwe-CT.

2. Izindleko: I-Granite iyinto eyigugu neyikhwalithi ephezulu, okusho ukuthi isisekelo somshini we-CT esenziwe nge-granite singabiza kakhulu kunezinye izinto, njengensimbi noma i-aluminium. Le mpahla ingakhuphula izindleko zokuqala zohlelo lwe-CT, ikakhulukazi kumabhizinisi amancane naphakathi noma amalabhorethri ocwaningo anesabelomali esilinganiselwe. Kodwa-ke, lokhu kungahle kuncishiswe izinzuzo zesikhathi eside zesisekelo somshini we-granite, njengokunemba okuthuthukisiwe, ukuzinza, nokuqina, kanye nezindleko zokulungisa ezincishisiwe, isikhathi sokungasebenzi, kanye nokushintsha.

Isiphetho

Izisekelo zomshini wegranite zinikeza izinzuzo eziningana kanye nokungalungi okumbalwa kwezicelo ze-CT zezimboni. Ukuqina, ukuqina, ukumanzisa, ukuzinza kokushisa, kanye nokusebenza kahle kwegranite kwenza kube yinto efanelekile yezinhlelo ze-CT ezinembile kakhulu nezisebenza kahle ezidinga ukunemba, ukuthembeka, kanye nokuguquguquka okumangalisayo. Isisindo kanye nezindleko zesisekelo somshini wegranite zingase zibe nezinselele ezithile, kodwa zinganqotshwa ngokuklama ngokucophelela, ukuhlela, kanye nokwenza ngcono uhlelo lwe-CT. Ngamafuphi, izisekelo zomshini wegranite ziwutshalomali oluwusizo nolufanele lwezinhlelo zokusebenza ze-CT zezimboni ezifuna imiphumela esezingeni eliphezulu kanye nezinzuzo zesikhathi eside.

Isikhathi sokuthunyelwe: Disemba 19-2023