Amadivaysi e-Optical waveguide positioning asetshenziselwa ukubeka ngokunembile ama-waveguides optical ezinhlelweni ezihlukahlukene, kusukela kwezokuxhumana kuya kumishini yezokwelapha. Uma kuziwa ekukhiqizweni kwalawa madivayisi, ukukhethwa kwendlela yokuhlanganisa kungaba nomthelela omkhulu kukhwalithi yawo, ukuqina, nokusebenza kwawo.

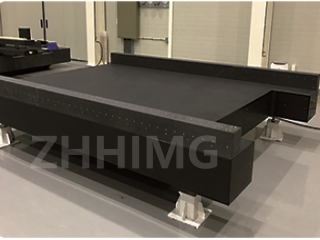

Enye yezindlela ezizuzisa kakhulu zokuhlanganisa amadivaysi e-optical waveguide positioning ukuhlanganisa i-granite. I-Granite iyimpahla eqinile futhi engeyona i-porous ehlinzeka ngenani lezinzuzo ngaphezu kwezinye izinto ezifana ne-aluminium noma ipulasitiki.

Okokuqala, i-granite izinzile ngokwedlulele futhi ine-coefficient ephansi yokwanda okushisayo. Lokhu kusho ukuthi ngeke inwebe noma incindeke kakhulu ngokushintsha kwezinga lokushisa, iqinisekise ukuthi amadivayisi ahlala ezinzile futhi ethembekile ngisho nasezimweni ezinzima. Lokhu kuzinza kubaluleke kakhulu ezinhlelweni zokusebenza ezinembayo, ezifana nezokuxhumana, lapho ukuma kwamagagasi kufanele kube neqiniso futhi kungaguquki.

Okwesibili, i-granite inzima kakhulu futhi ihlala isikhathi eside. Ayiklwebheki kalula noma ayilimele, okuyenza ifaneleke ukusetshenziswa ezindaweni zokukhiqiza lapho amadivayisi angase aguge. I-Granite iphinde imelane nokugqwala kwamakhemikhali, okubalulekile ekusebenzeni lapho amadivaysi angase ahlangane namakhemikhali angalimaza ezinye izinto.

Ngaphezu kwalokho, ukuminyana okuphezulu kwe-granite kuyenza ibe yinto enhle kakhulu yokudambisa ukudlidliza. Lokhu kubalulekile kumadivayisi e-optical waveguide positioning lapho nokudlidliza okuncane kungaphazamisa ukusebenza kwesistimu. Ukusetshenziswa kwegwadle kungasiza ukumunca lokhu kudlidliza, kuqinisekise ukuthi izisetshenziswa zihlala zizinzile futhi zithembekile.

Ngaphezu kwezakhiwo zayo ezibonakalayo, ukuhlanganiswa kwe-granite nakho kunikeza izinzuzo eziningi ezisebenzayo. Isibonelo, i-granite ingenziwa ngomshini ukuze ibekezelelane kakhulu, iqinisekise ukuthi amadivaysi enziwe ngokunembile ukuze acacise imininingwane. I-Granite iphinde ibe lula ukuyihlanza nokuyinakekela, ukuqinisekisa ukuthi izisetshenziswa zihlala zihlanzekile futhi zingenakho ukungcola.

Okokugcina, i-granite kulula ukusebenza ngayo futhi ingacutshungulwa kusetshenziswa amasu ahlukene, okuhlanganisa ukukhanda kwe-CNC, ukugaya, nokupholisha. Lokhu kuguquguquka kukwenza kube ukukhetha okudumile ezinhlobonhlobo zezinhlelo zokusebenza, hhayi nje amadivaysi okubeka ama-waveguide optical.

Sengiphetha, izinzuzo zokuhlanganisa i-granite zamadivayisi okubeka i-waveguide optical zicacile. Ukuzinza kwe-Granite, ukuqina, ukumelana nokugqwala kanye nezakhiwo ezidambisa ukudlidliza kuyenza ibe inketho ekahle yezinhlelo zokusebenza ezinembayo lapho ukunemba nokuthembeka kubaluleke kakhulu. Ngaphezu kwalokho, ukusebenziseka kalula kwemishini nokugcinwa kwemishini kukwenza kube ukukhetha okusebenzayo nokungabizi kakhulu kubakhiqizi.

Isikhathi sokuthumela: Dec-04-2023