I-Granite yitshe lemvelo elaziwa ngokuqina kwalo, amandla, kanye nokumelana nokuguguleka. Ngenxa yalezi zakhiwo, iyinto efanelekile yokusetshenziswa emishinini yokukhiqiza embonini ye-semiconductor, njengemishini yokucubungula i-wafer. Kulesi sihloko, sizohlola izinzuzo eziningi ezinikezwa yi-granite kumongo wokukhiqizwa kwemishini yokucubungula i-wafer.

Okokuqala nokubaluleke kakhulu, i-granite ine-coefficient ephansi kakhulu yokwanda kokushisa. Lokhu kusho ukuthi ayikhuli noma ayinciphisi kakhulu ngenxa yezinguquko ekushiseni. Lena yimpahla ebaluleke kakhulu yemishini yokucubungula i-wafer, okumele igcine ukubekezelelana okunembile ukuze igweme ukulimaza ama-wafer athambile acutshungulwayo. Uma imishini yenziwe ngezinto ezine-coefficient ephezulu yokwanda kokushisa, khona-ke ngisho nezinguquko ezincane ekushiseni zingabangela ukuthi imishini ikhule noma inciphe, okuholela ekungalungini ekucutshungulweni kwama-wafer.

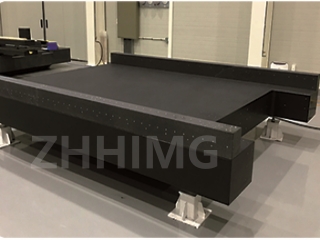

Enye inzuzo ye-granite ukuthi izinga layo eliphezulu lokuzinza. Iyinto eqinile kakhulu futhi eqinile engagugi kalula noma iguge ngokuhamba kwesikhathi. Lokhu kusho ukuthi imishini eyenziwe nge-granite ingasetshenziswa iminyaka eminingi ngaphandle kokudinga ukushintshwa noma ukulungiswa, ngisho noma isetshenziswa kakhulu. Ngaphezu kwalokho, i-granite inokuqina okuphezulu kakhulu, okusho ukuthi ingagcina isimo sayo nosayizi wayo ngokuhamba kwesikhathi naphezu kokushintsha kwezinga lokushisa noma umswakama.

I-granite nayo imelana kakhulu nokugqwala kwamakhemikhali, okwenza ibe yinto efanelekile yokusetshenziswa ezindaweni zamakhemikhali ezinzima ezivame ukucutshungulwa nge-wafer. Amakhemikhali amaningi asetshenziswa ekucutshungulweni kwe-wafer angaba yingozi kakhulu ezinsimbini nakwezinye izinto, okuholela ekulimaleni noma ekwehlulekeni kwemishini. Nokho, i-granite ayithinteki kakhulu kula makhemikhali, okwenza ukuthi isebenze kahle futhi igcine ubuqotho bayo besakhiwo ngokuhamba kwesikhathi.

Ngaphezu kwalezi zici zokusebenza, i-granite inezinye izinzuzo eziningi uma isetshenziswa emishinini yokucubungula i-wafer. Inokubukeka okukhangayo kakhulu, enephethini yokusanhlamvu ehlukile ejabulisa ubuhle futhi eyingqayizivele. Lokhu kungaba yinto ebalulekile ekucabangeni kwezindawo zokukhiqiza ze-semiconductor ezisezingeni eliphezulu lapho ukubukeka kubalulekile khona. Ngaphezu kwalokho, i-granite iyinto yemvelo ehlala isikhathi eside futhi enobungani nemvelo, okwenza kube inketho ekhangayo yezinkampani ezibeka phambili ukusimama.

Ekuphetheni, izinzuzo zokusebenzisa i-granite ekukhiqizweni kwemishini yokucubungula i-wafer ziningi futhi zibalulekile. Kusukela ku-coefficient yayo ephansi yokwanda kokushisa kuya emazingeni ayo aphezulu okuqina nokumelana nokugqwala kwamakhemikhali, i-granite inikeza isethi eyingqayizivele yezici ezenza ibe yinto efanelekile kulo mkhakha. Ngakho-ke, iyindlela ekhethwayo yabakhiqizi abaningi be-semiconductor emhlabeni jikelele, futhi kungenzeka ukuthi izohlala injalo esikhathini esizayo esibonakalayo.

Isikhathi sokuthunyelwe: Disemba 27-2023