.

Embonini yemishini yokulawula izinombolo ye-CNC, ukunemba, ukuzinza nokuqina yizinkomba ezibalulekile zokulinganisa ukusebenza kwemishini. I-Granite, enezici zayo ezivelele zomzimba namakhemikhali, kancane kancane isibe yinto ebalulekile ekukhiqizeni imishini ye-CNC futhi isetshenziswa kabanzi kumadivayisi abalulekile ahlukahlukene, ifaka umfutho omusha ekuthuthukisweni kwemboni. .

I. Izimo Zokusebenza zeGranite ku-CNC Numerical Control Equipment

Isisekelo sesikhungo somshini wokunemba okuphezulu

Ezinkambini ezinjengokucubungula isikhunta ngokunemba kanye nokukhiqizwa kwezingxenye zezindiza, izidingo eziphakeme kakhulu zibekwe ekunembeni kokuma futhi ziphinda ukunemba kokuma kwezikhungo zomshini. I-Granite, ngokuzinza kwayo okuhle kakhulu, ivame ukusetshenziswa njengesisekelo sezikhungo zemishini ephezulu. Isakhiwo sayo esiminyene kanye nokuqina okuphezulu kungasekela ngokuphumelelayo izingxenye eziyinhloko zethuluzi lomshini njenge-spindle nama-guide rails, ukunciphisa amaphutha okucubungula okubangelwa ukuguqulwa kwesisekelo. Isibonelo, lapho ucubungula isikhunta se-aero engine blades enezindawo eziyinkimbinkimbi ezigobile, isikhungo somshini sisebenzisa isisekelo se-granite singaqinisekisa ukwenziwa okunembile kwendlela yamathuluzi futhi sithuthukise ukunemba kokwakheka kwezibunjwa. .

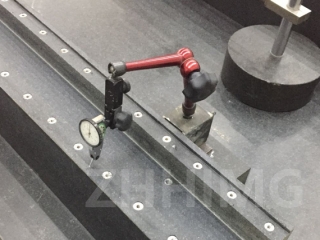

2. Ipulatifomu yomshini wokulinganisa enezixhumanisi ezintathu

Umshini wokulinganisa ohlanganisa izinto ezintathu uyisisetshenziswa esibalulekile sokuhlolwa kwekhwalithi kumishini ye-CNC, futhi ukunemba kwawo kokulinganisa kuthinta ngqo ikhwalithi yomkhiqizo. Amaplathifomu egwadle, anokucaba kwawo okuphezulu kakhulu (kufika ku-±0.1μm/m) kanye nobuqhwaga obuphansi kakhulu (Ra≤0.02μm), ahlinzeka ngendawo eyireferensi ezinzile yokuhlola ama-probe. Lapho kuhlolwa ubukhulu, umumo nokubekezelela indawo kwezingxenye ezinembayo, izinkundla zegwadle zingagwema ngempumelelo amaphutha okulinganisa abangelwa ukuguquguquka kwazo noma izindawo ezingalingani, ziqinisekise ukunemba nokuthembeka kwedatha yokuhlola. .

3. Izinsimbi zomhlahlandlela zamathuluzi omshini we-CNC

Ukusebenza kwesitimela somhlahlandlela kunquma ukushelela nokunemba kokunyakaza kwethuluzi lomshini. Amarayili omhlahlandlela we-granite afaka i-coefficient ephansi yokungqubuzana nokumelana nokugqokwa okuqinile. Uma kuqhathaniswa nama-rails omhlahlandlela wensimbi, anganciphisa ukuguga kwezingxenye ezihambayo futhi ehlise imvamisa yokugcinwa. Ngaleso sikhathi, ukusebenza kwayo okuhle kakhulu kokudambisa kungamunca ngempumelelo ukudlidliza ngesikhathi sokusebenza kwethuluzi lomshini futhi kuthuthukise ikhwalithi yendawo esebenza ngomshini. Ezinqubweni zokusika ngesivinini esikhulu, ama-rail omhlahlandlela we-granite angagcina ithuluzi lokusika lisesimweni esizinzile sokusika, ukunciphisa ukukhahlamezeka kwendawo yokusebenza, futhi kuthuthukise ukusebenza kahle kokucubungula kanye nekhwalithi yomkhiqizo. .

4. Ithebula lokusebenzela lomshini wokukhipha ugesi wokukhipha ugesi

Ngesikhathi senqubo yomshini wokukhipha ugesi, amazinga okushisa aphezulu kanye nokuphazamiseka kwe-electromagnetic kukhiqizwa, okubeka izidingo eziphezulu ekuzinzeni nasekufakeni i-worktable. I-Granite ayigcini nje ngokuba nokuzinza okuhle kakhulu kwe-thermal, ekwazi ukumelana nezinguquko zokushisa ngesikhathi sokucubungula, kodwa futhi inezakhiwo zemvelo zokuhlukanisa futhi ayithinteki ukuphazamiseka kwe-electromagnetic. Ngakho-ke, amabhentshi okusebenza e-granite anganikeza indawo yokusebenza ezinzile yomshini wokukhipha ugesi, ukuqinisekisa ukunemba kokucubungula kanye nekhwalithi ephezulu. .

Ii. Izinzuzo Eziyinhloko zeGranite ku-CNC Numerical Control Equipment

Ukuqina okushisayo okuvelele

Ngesikhathi sokusebenza okuqhubekayo kwesikhathi eside kwemishini ye-CNC, inani elikhulu lokushisa liyakhiqizwa, okubangela ukunwetshwa kokushisa nokuncipha kwezingxenye zemishini. I-coefficient yokunwetshwa okushisayo kwe-granite iphansi kakhulu (kuphela 4-8 × 10⁻⁶/℃), futhi ubukhulu bayo buhlala bucishe bushintshe lapho izinga lokushisa lishintsha, elingagwema ngempumelelo amaphutha okucubungula nokuphambuka kokulinganisa okubangelwa ukuwohloka kokushisa. Isibonelo, ezindaweni ezinezinga lokushisa eliphezulu, okokusebenza kwe-CNC okunezisekelo zegwadle kusengagcina ukunemba kokucubungula okuzinzile, iqinisekisa ukuthi ikhwalithi yomkhiqizo ayithintwa ukushintsha kwezinga lokushisa. .

2. Ukusebenza okuhle kakhulu kwe-anti-vibration

Ngesikhathi senqubo yomshini we-CNC, ukusebenza ngesivinini esiphezulu kwethuluzi lomshini kanye namandla okusika kuzodala ukudlidliza, okuthinta ukunemba kwemishini kanye nekhwalithi ephezulu. Isakhiwo sekristalu esiyingqayizivele esingaphakathi kwegwadle siyinikeza ukusebenza okuhle kakhulu kokudambisa, okusivumela ukuthi sinciphise ngokushesha amandla okudlidliza angaphandle futhi sinciphise ukuphazamiseka kokudlidliza. Idatha yokuhlola ibonisa ukuthi isilinganiso somswakama we-granite singafinyelela ku-0.05-0.1, okuphindwe izikhathi ezingu-5-10 kunezinto zensimbi. Inganciphisa ngempumelelo ukudlidliza kwethuluzi kanye nokuphaphazela kwendawo yokusebenza, futhi ithuthukise ukunemba kokucubungula nokuqeda kwangaphezulu. .

3. Ukuqina okuphezulu nokumelana nokugqoka

I-Granite inokuminyana okuphezulu (kufika ku-2.6-3.0g /cm³) nokuqina okukhulu (ngokuqina kwe-Mohs okungu-6-7), futhi ifaka ukuqina okuhle kakhulu nokumelana nokugqokwa. Uma ingaphansi kwemithwalo esindayo kanye nokunyakaza kwemishini okuvamile kwemishini ye-CNC, izingxenye zegwadle azijwayele ukuguga noma ukuguga futhi zingagcina isimo sokunemba okuphezulu isikhathi eside. Ngokwezibalo, isikhathi sokugcinwa okunembayo kwemishini ye-CNC esebenzisa izingxenye zegwadle singaba side izikhathi ezi-3 kuya kwezi-5 kunezisetshenziswa zensimbi zendabuko, kunciphisa kakhulu izindleko zokugcinwa kwemishini kanye nesikhathi sokuphumula. .

4. Ukuzinza kwamakhemikhali okuqinile

Enqubweni yokwenza imishini ye-CNC, ama-reagents amakhemikhali afana noketshezi lokusika kanye nezinto zokugcoba avame ukusetshenziswa, futhi lezi zinto zingase zidale ukugqwala ezingxenyeni zemishini. I-Granite inezinto zamakhemikhali ezizinzile, ububanzi bokubekezelela i-pH (1-14), ingamelana nokuguguleka kwamakhemikhali avamile, futhi ayijwayele ukugqwala noma ukugqwala. Lesi sici asigcini nje ukwandisa impilo yesevisi yezingxenye zemishini, kodwa futhi siqinisekisa ukuhlanzeka kwendawo yokucubungula, ukugwema umthelela wekhwalithi yomkhiqizo ngenxa yokungcoliswa kwamakhemikhali. .

Ngokumelene nokwasemuva kwemboni yemishini yokulawula izinombolo ye-CNC yokuphishekela ukunemba okuphezulu nokusebenza kahle okuphezulu, i-granite, nezinzuzo zayo ezifana nokuzinza okushisayo, ukumelana nokudlidliza, ukuqina okuphezulu kanye nokuzinza kwamakhemikhali, idlala indima engenakushintshwa ezinhlobonhlobo zemishini ebalulekile. Ngokuthuthuka okuqhubekayo kobuchwepheshe, izinto ze-granite zizosetshenziswa kabanzi emkhakheni we-CNC, ukukhuthaza imboni ukuthi ithuthukele ekunembeni okuphezulu kanye nekhwalithi ephezulu..

Isikhathi sokuthumela: May-24-2025