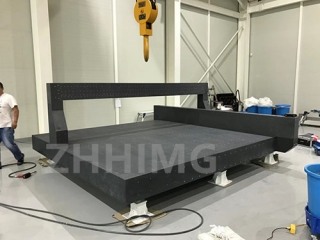

Umbhede womshini we-granite usetshenziswa kabanzi emikhiqizweni ye-Wafer Processing Equipment ngenxa yezakhiwo zawo ezinhle kakhulu. I-Granite iyidwala eliyi-igneous elivela ngokwemvelo elaziwa ngokuqina kwalo okuphezulu, ubulukhuni, kanye nokumelana nokuguguleka. Ngenxa yalokho, i-granite isetshenziswe kakhulu embonini yokukhiqiza njengento yokusetshenziswa kwemibhede yomshini ezinhlotsheni ezahlukene zokusebenza, ikakhulukazi lezo ezidinga izinga eliphezulu lokunemba nokuzinza. Nazi ezinye zezindawo zokusetshenziswa kombhede womshini we-granite emikhiqizweni ye-Wafer Processing Equipment:

1. Ukukhiqizwa Kwe-semiconductor

Ukukhiqizwa kwe-semiconductor kungenye yezinqubo ezibaluleke kakhulu neziyinkimbinkimbi embonini ye-elekthronikhi. Ukukhiqizwa kwama-wafer asezingeni eliphezulu kudinga ukusetshenziswa kwemishini enembile kakhulu ekwazi ukufeza ukubekezelelana okungaphansi kwe-micron eyodwa. Ngakho-ke, imibhede yomshini we-granite isetshenziswa emikhiqizweni ye-Wafer Processing Equipment ukuqinisekisa ukuthi imishini igcina ukunemba kwayo, ukuzinza, kanye nokuphindeka kwayo esikhathini eside sokusetshenziswa. Ngaphezu kwalokho, imibhede yomshini we-granite ingamunca ukudlidliza okukhiqizwa ngesikhathi senqubo yokukhiqiza, kunciphisa ingozi yokulimala kwama-wafer athambile nezinye izingxenye.

2. Ukukhiqizwa kwe-Optics

Ukukhiqizwa kwe-optical kungenye indawo esetshenziswayo yemibhede yomshini we-granite emikhiqizweni ye-Wafer Processing Equipment. Imibhede yomshini we-granite isetshenziswa ekukhiqizweni kwezingxenye ze-optical ezinembayo ephezulu, njenge-lens, ama-prism, izibuko, kanye nezihlungi, ezidinga izinga eliphezulu lokuzinza nokunemba ngesikhathi senqubo yokukhiqiza. Imibhede yomshini we-granite inganikeza ukuzinza nokuqina okudingekayo emishinini, ivimbele noma yikuphi ukunyakaza okungafuneki okungathinta ikhwalithi yomkhiqizo wokugcina. Ngaphezu kwalokho, imibhede yomshini we-granite ine-coefficient ephansi yokwanda kokushisa, okwenza ifaneleke ukusetshenziswa ezindaweni ezilawulwa amazinga okushisa.

3. Ukukhiqizwa Kwemishini Yezokwelapha

Ukukhiqizwa kwemishini yezokwelapha kuyinkambu ekhethekile kakhulu edinga ukunemba nokunemba ekukhiqizweni kwezingxenye ezahlukahlukene, njengezifakelo, izitho zokufakelwa, kanye nezinsimbi zokuhlinza. Imibhede yomshini we-granite isetshenziswa emikhiqizweni ye-Wafer Processing Equipment ngesikhathi sokukhiqiza imishini yezokwelapha, ukuqinisekisa ukuthi imishini ingagcina ukunemba kwayo nokuphindaphindeka kwayo ngokuhamba kwesikhathi. Ngaphezu kwalokho, imibhede yomshini we-granite kulula ukuyihlanza, okwenza kube lula ukugcina ukuhlanzeka nokungabi namagciwane okudingekayo ekukhiqizweni kwamadivayisi ezokwelapha.

4. Izindiza kanye Nokuvikela

Izimboni zezindiza nezokuvikela ziyizindlela ezimbili ezibaluleke kakhulu zokusetshenziswa kwemikhiqizo ye-Wafer Processing Equipment. Lezi zimboni zidinga ukukhiqizwa kwezingxenye ezingamelana nokushisa okukhulu, ingcindezi, ukushaqeka, kanye nokudlidliza. Imibhede yomshini we-granite isetshenziswa kulezi zimboni ukuhlinzeka ngeplatifomu eqinile neqinile yemishini ekhiqiza izingxenye ezibalulekile, njengezinhlelo zokuqondisa izibhamu, izinjini zejethi, kanye nezingxenye zesathelayithi. Ngaphezu kwalokho, imibhede yomshini we-granite iyakwazi ukumelana nezimo zemvelo ezimbi kakhulu futhi inezakhiwo ezinhle kakhulu zokumelana nokushaqeka, okwenza kube ukukhetha okuhle kwezinhlelo zokusebenza zezindiza nezokuvikela.

Ekuphetheni, imikhiqizo ye-Wafer Processing Equipment idlala indima ebalulekile ekukhiqizweni kwezingxenye ezahlukahlukene ezimbonini ezahlukene. Imibhede yomshini we-granite iyizingxenye ezibalulekile zemikhiqizo ye-Wafer Processing Equipment, enikeza ukuzinza okudingekayo, ukunemba, kanye nokuthembeka okudingekayo ekusetshenzisweni okunembe kakhulu. Ngezakhiwo zayo ezinhle kakhulu, imibhede yomshini we-granite isibe ukukhetha okuthandwayo kwezicelo ekukhiqizweni kwe-semiconductor, ekukhiqizweni kwe-optics, ekukhiqizweni kwemishini yezokwelapha, kanye nasezindiza kanye nokuzivikela.

Isikhathi sokuthunyelwe: Disemba-29-2023