Izingxenye ze-granite mechanical ziye zaba yingxenye ebalulekile yamadivayisi okucubungula ngokunemba. Izici zazo ezingokwemvelo zokuqina okuphezulu, ukuzinza okuphezulu, ukwanda okuphansi kokushisa, kanye nokumelana nokugqwala okuhle kakhulu kuzenza zibe yinto ebalulekile ekusetshenzisweni lapho ukunemba nokunemba kubalulekile khona. Izimboni eziningi zamukela ukusetshenziswa kwezingxenye ze-granite mechanical, okuhlanganisa i-metrology, ukukhiqizwa kwe-semiconductor, izinsimbi zokukhanya, kanye ne-aerospace.

Ekusetshenzisweni kwe-metrology, ukulinganisa ngokunemba kubaluleke kakhulu, futhi izingxenye ze-granite mechanical zisebenza njengezindinganiso ezifanele zokubhekisela ngezinjongo zokulinganisa. Izazi ze-metrology zisebenzisa amapuleti e-granite nama-cubes ukusetha izindiza zokubhekisela kanye nezindawo zokubhekisela, ngokulandelana. Lezi zingxenye zinikeza indawo eyisicaba nezinzile kakhulu yokulinganisa ngokunembile izici ezincane, njengobukhulu, ukuphakama, kanye nokuba sicaba. Ukuqina okuphezulu kobukhulu bezingxenye ze-granite mechanical kuqinisekisa ukuthi ukunemba kwazo kuhlala kungaphazanyiswa ngokuhamba kwesikhathi, okwenza kube kuhle kakhulu ekusetshenzisweni kwesikhathi eside ku-metrology.

Ekukhiqizweni kwe-semiconductor, ukunemba kanye nekhwalithi yemikhiqizo kubalulekile ekusebenzeni kwayo kanye nokuthembeka kwayo. Izingxenye ze-granite mechanical ezifana nama-chucks, ama-wafer carriers, nama-die pads zinikeza ipulatifomu ezinzile nefanayo yokucubungula nokuhlanganisa ama-wafer e-semiconductor. Ukuqina okuphezulu kanye nokwanda okuphansi kokushisa kwezingxenye ze-granite kusiza ukunciphisa ukwenzeka kokugoba kanye nokuphambuka ngesikhathi sokucubungula, okuholela ekuvuneni okungcono kanye namaphutha ambalwa. Ukumelana okuhle kokugqwala kwe-granite kuqinisekisa ukuthi lezi zingxenye zihlala zithembekile futhi ziqinile ezindaweni zamakhemikhali ezinzima.

Ekusetshenzisweni kwezinsimbi zokukhanya, izidingo zokunemba nokunemba ziphakeme ngokulinganayo. Izingxenye ze-granite zinikeza isisekelo esizinzile nesingenazo izidlidlizi sokuthuthukiswa nokulinganiswa kwezinsimbi zokukhanya ezifana nama-telescope, ama-interferometer, kanye nezinhlelo ze-laser. Ukwanda okuphansi kokushisa kwezingxenye ze-granite mechanical kunciphisa imiphumela yokushintsha kwezinga lokushisa ekusebenzeni kwezinsimbi zokukhanya, okuthuthukisa ukunemba nokuthembeka kwazo. Ngaphezu kwalokho, ukuqina okuphezulu kwezingxenye ze-granite kwenza kube lula ukwakhiwa kwamadivayisi amakhulu nasindayo ngaphandle kokubeka engcupheni ukuzinza kwawo.

Ezisetshenzisweni zezindiza, ukusetshenziswa kwezingxenye ze-granite mechanical kuya ngokuya kuthandwa ngenxa yokukhanya kwazo, amandla aphezulu, kanye nokumelana nokuwohloka kwemvelo. Izinhlanganisela ezisekelwe ku-granite, njenge-"Granitium," zithola isithakazelo njengezinto zokwakha ezingcono kakhulu zokwakha izingxenye ze-mechanical ezinembayo elula ezindizeni naseziphuphuthekeni. Lezi zinto zinikeza izakhiwo ezinhle kakhulu ze-mechanical kanye ne-thermal ezibalulekile ekusebenzeni kwezinhlelo ezinembayo emkhathini nasezindizeni.

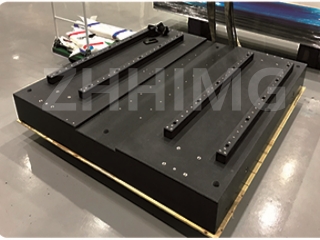

Ekuphetheni, izingxenye ze-granite mechanical zidlala indima ebalulekile ekuthuthukisweni nasekusebenzeni kwemikhiqizo yedivayisi yokucubungula ngokunembile ezimbonini ezahlukahlukene. Inhlanganisela yazo eyingqayizivele yezakhiwo, okuhlanganisa ukuqina okuphezulu, ukwanda okuphansi kokushisa, kanye nokuzinza okuhle kakhulu, kuzenza zibaluleke kakhulu ezinhlelweni zokusebenza ezidinga ukulinganiswa okunembile, ukucubungula okunembile, kanye nokusebenza okuthembekile. Uhlobo oluguquguqukayo lwezingxenye ze-granite luholele ekusetshenzisweni kwazo kumadivayisi ahlukahlukene, okuhlanganisa izinsimbi ze-metrology, imishini ye-semiconductor, amadivayisi optical, kanye nezakhiwo zezindiza. Njengoba ubuchwepheshe buthuthuka, ukusetshenziswa kwezingxenye ze-granite mechanical kulindeleke ukuthi kukhule, kuthuthukiswe ukunemba nokuthembeka kwezinhlelo zezimboni zanamuhla.

Isikhathi sokuthunyelwe: Novemba-25-2023