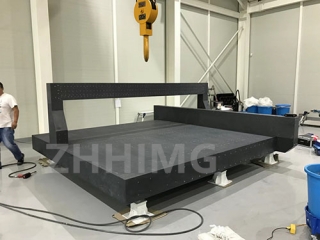

Amatafula e-Granite XY asetshenziswa kabanzi ezimbonini nasezinhlelweni ezahlukahlukene. Ngokuvamile asetshenziswa njengezinkundla zokubeka ngokunemba ukuhlola, ukuhlola, kanye nokuhlanganisa ucwaningo kanye nentuthuko (R&D), ukukhiqiza, kanye nezikhungo zezemfundo. Lawa matafula akhiwe ngebhulokhi le-granite elineziqondiso zokunemba kanye nezikulufo zebhola. Ubuso be-granite bunobucwebe obuphezulu kanye nokuqedwa kobuso, okwenza kube yinto efanelekile yokusetshenziswa lapho kudingeka khona ukunemba okuphezulu kanye nokuzinza. Kulesi sihloko, sizohlola izindawo zokusetshenziswa kwamatafula e-granite XY.

1. I-Metrology

I-Metrology iwucwaningo lwesayensi lokulinganisa. Kulo mkhakha, ososayensi be-metro basebenzisa izinsimbi zokunemba ukukala ubude, ama-engeli, kanye nobuningi obuthile obubonakalayo. Amatafula e-Granite XY avame ukusetshenziswa ekusetshenzisweni kwe-metrology njengeplatifomu ezinzile neqondile yohlu lwezinsimbi zokulinganisa nokulinganisa. Asetshenziswa ezinhlelweni ze-metrology ezinobukhulu, njengemishini yokulinganisa (ama-CMM), abahloli bokulukhuni kobuso, kanye nama-profilometer.

2. Ukuhlolwa Nokuhlolwa Kwamehlo

Amatafula e-Granite XY asetshenziswa ezinhlelweni zokuhlola nokuhlola i-optical njengeplatifomu yokubeka amasampula okuhlola, amalensi, kanye nezinye izinto zokukhanya. I-Granite inikeza izakhiwo ezinhle kakhulu zokunciphisa umswakama, ezibalulekile ezinhlelweni zokusebenza lapho ukudlidliza kungathinta khona izilinganiso, njengokuhlola i-optical. Ukubeka kahle indawo nakho kubalulekile ekulinganisweni nasekuhlolweni kwe-optical, futhi amatafula e-granite XY anganikeza ukunemba okungenakuqhathaniswa kulezi zinhlelo zokusebenza.

3. Ukuhlolwa kwe-Wafer

Embonini ye-semiconductor, ama-wafer ayahlolwa ukuze kutholakale amaphutha nokuqinisekisa ikhwalithi yomkhiqizo. Amatafula e-Granite XY asetshenziswa kabanzi ezinhlelweni zokuhlola ama-wafer njengeplatifomu enembile nezinzile yenqubo yokuhlola. Amatafula abalulekile ekubekeni i-wafer ngaphansi kwe-microscope noma eminye imishini yokuhlola, okuvumela ukuthwebula izithombe nokulinganisa amaphutha ngesinqumo esiphezulu.

4. Ukuhlanganiswa Nokukhiqiza

Amatafula e-Granite XY asetshenziswa ekukhiqizeni nasekuhlanganiseni lapho kudingeka khona indawo eqondile. Embonini yezimoto, isibonelo, amatafula e-granite XY asetshenziselwa ukubeka nokuhlola izingxenye zezimoto ukuqinisekisa ukuthi ziyahlangabezana nezimfuneko ezidingekayo. Ekukhiqizeni izinto zikagesi, asetshenziselwa ukubeka izingxenye ngokunembile ngesikhathi sokuhlanganiswa. Amatafula e-Granite XY angasetshenziswa nasekukhiqizeni izindiza kanye namadivayisi ezokwelapha, lapho ukubeka ngokunemba okuphezulu kubalulekile.

5. I-Microscopy kanye ne-Imography

Ezinhlelweni ze-microscopy kanye nezithombe, amatafula e-granite XY afaneleka kakhulu ekubekeni amasampula ukuze kuthathwe izithombe ezinesinqumo esiphezulu. Lawa matafula angasetshenziswa ku-confocal microscopy, ku-super-resolution imaging, nakwamanye amasu e-microscopy athuthukile adinga indawo eqondile kakhulu. Lawa matafula angasetshenziswa ukubeka isampula ngaphansi kwe-microscope noma eminye imishini yokuthwebula izithombe, okwenza kube lula ukuthwebula izithombe okunembile nokuphindaphindwayo.

6. Amarobhothi

Amatafula e-Granite XY asetshenziswa ezinhlelweni zamarobhothi, ikakhulukazi ekubekeni izingalo zamarobhothi nezinye izingxenye. Lawa matafula ahlinzeka ngeplatifomu enembile nezinzile yezingalo zamarobhothi ukuze zenze imisebenzi yokukhetha nokubeka kanye neminye imisebenzi edinga ukubekwa okunembile. Asetshenziswa futhi ekulinganisweni nasekuhlolweni kwamarobhothi.

Ekuphetheni, izindawo zokusetshenziswa kwamatafula e-granite XY zikhulu futhi ziyahlukahluka. Lawa matafula abalulekile ezimbonini ezahlukahlukene, kusukela ekukhiqizeni kuya ocwaningweni lwezemfundo, kuya ku-metrology, nokuningi. Anikeza ukunemba nokuqina okungenakuqhathaniswa, okwenza afaneleke kakhulu ekusetshenzisweni lapho ukunemba okuphezulu kubalulekile khona. Isidingo esikhulayo sezinsimbi ezithuthukisiwe, ukulawulwa kwekhwalithi, kanye nokwenza izinto ngokuzenzakalela kulindeleke ukuthi sikhuthaze ukukhula kwemakethe yamatafula e-granite XY eminyakeni ezayo.

Isikhathi sokuthunyelwe: Novemba-08-2023