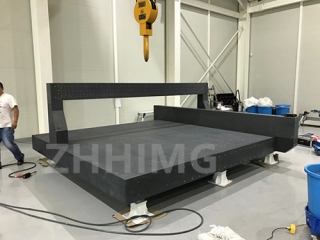

Ukuhlanganiswa kwe-granite enembile kubhekisela enkambisweni yokukhiqiza ehilela ukusetshenziswa kwezingxenye ze-granite ezisikwe ngokucophelela futhi ezilinganisiwe ezisetshenziswa ekuhlanganisweni kwamadivayisi ahlukahlukene. Ukuhlanganiswa kwe-granite enembile kunezinhlelo zokusebenza ezahlukahlukene, okuhlanganisa ukuthuthukiswa kwemikhiqizo yedivayisi yokuhlola iphaneli ye-LCD.

Imikhiqizo Yedivayisi Yokuhlola Iphaneli ye-LCD:

Imikhiqizo yedivayisi yokuhlola iphaneli ye-LCD yimishini kagesi esetshenziswa ekulawuleni ikhwalithi yamaphaneli okubonisa i-liquid crystal (LCD). Asiza ekutholeni amaphutha ahlukahlukene njengokushiswa kanye nama-pixel afile, aqinisekise ukukhiqizwa kombala okunembile, kanye nokukhanya okuhle kakhulu. Ukuhlanganiswa kwe-granite okunembile kushintshe kakhulu intuthuko yamadivayisi anjalo, kwathuthukisa kakhulu ukusebenza kwawo, kanye nekhwalithi yamaphaneli e-LCD awahlolayo.

Ukusetshenziswa kwe-Precision Granite Assembly ekuthuthukisweni kwamadivayisi okuhlola amaphaneli e-LCD:

1. Ukulinganisa Ngokunembile:

Izingxenye zegranite zisetshenziselwa ukudala indawo eyisicaba lapho kubekwa khona amaphaneli e-LCD ngesikhathi sokuhlolwa, okuqinisekisa ukulevelishwa okunembile nokunembile. Izingxenye zegranite ezisetshenziselwa lokhu zakhiwe kahle ukuze kufezwe ukunemba okuphezulu nokuzinza, okuqinisekisa ukunemba okuphezulu kokuhlolwa.

2. Ukuqina Nokuqina:

Izingxenye ze-granite ziphakathi kwezinto ezizinzile nezihlala isikhathi eside ezisetshenziswa ku-precision factor yedivayisi yokuhlola iphaneli ye-LCD. Zihlinzeka ngeplatifomu yokulwa nokudlidliza yemishini yokuhlola, okuqinisekisa ukunemba nokuthuthukisa ukusebenza. Ukuqina kwezingxenye ze-Granite kunciphisa kakhulu izindleko zokugcinwa kwemishini futhi kuvumela ukukhiqiza amadivayisi anembile angamelana nezimo ezinzima kanye nezimo ezizungezile.

3. Ukuzinza Kokushisa:

Esinye sezici eziyingqayizivele zezingxenye ze-granite ukuthi zinokuzinza kokushisa okumangalisayo. Lesi sici sizenza zibe zilungele ukusetshenziswa ekukhiqizeni amadivayisi okuhlola amaphaneli e-LCD njengoba zisebenza kahle ngisho nalapho zibhekene nokushintshashintsha kwezinga lokushisa. Ukuzinza kokushisa okunikezwa izingxenye zokuhlanganisa i-granite enembile kuqinisekisa ukuthi amaphaneli e-LCD ahlolwa ngaphansi kwezimo zokushisa ezifanele, ngaleyo ndlela kufezwe ukunemba okuphezulu futhi kukhiqizwe imikhiqizo engcono kakhulu nekhwalithi ephezulu.

4. Izindinganiso Zokulinganisa Ezisezingeni Eliphezulu:

Izingxenye zokuhlanganisa i-granite eqondile zisetshenziselwa ukuthuthukisa amazinga okulinganisa asetshenziswa ekukhiqizweni kwemikhiqizo yamadivayisi okuhlola amaphaneli e-LCD. Izindinganiso zokulinganisa ezisezingeni eliphezulu ziqinisekisa ukuthi amadivayisi ahlangabezana nezindinganiso zokunemba okuphezulu, ukunemba, kanye nokuzinza ezidingekayo ekuhlangabezaneni nezidingo zemakethe zamaphaneli e-LCD asezingeni eliphezulu.

5. Iphutha Elincishisiwe:

Amaphutha kumadivayisi okuhlola amaphaneli e-LCD anemiphumela ebalulekile njengoba engase aholele ekukhiqizweni kwamakhulu amaphaneli e-LCD anephutha. Izingxenye zokuhlanganisa i-granite eqondile zenziwa ngokucophelela ukuze kuncishiswe izinga lamaphutha ngesikhathi sokulinganisa idivayisi, ngaleyo ndlela kuthuthukiswe ukunemba nokunemba kokuhlolwa.

6. Ukukhiqiza Okuthuthukisiwe:

Izingxenye zokuhlanganisa i-granite eqondile zithuthukisa umkhiqizo wamadivayisi okuhlola amaphaneli e-LCD. Zivumela ukukhiqizwa kwamadivayisi aqinile, azinzile, futhi athembekile enza ukuhlolwa okusheshayo nokunembile. Ukusebenza okuphezulu kwezingxenye zokuhlanganisa i-granite eqondile kuqinisekisa ikhwalithi ephezulu yephaneli ye-LCD, okunciphisa isikhathi sokukhiqiza kanye nokuchitheka kwezinto.

Isiphetho:

Ngamafuphi, ukuhlanganiswa kwe-precision granite kudlala indima ebalulekile ekuthuthukisweni kwemikhiqizo yedivayisi yokuhlola iphaneli ye-LCD esezingeni eliphezulu. Kuhlinzeka ngokunemba nokunemba okudingekayo ukukhiqiza amaphaneli e-LCD asezingeni eliphezulu, ngaleyo ndlela kuthuthukiswe ikhwalithi yokuphila iyonke. Ukusetshenziswa kokuhlanganiswa kwe-precision granite ekukhiqizweni kwamadivayisi okuhlola iphaneli ye-LCD kunikeza amathuba amasha esikhathi esizayo salobu buchwepheshe, obuqhubeka nokuzuzisa imboni yokukhiqiza kagesi iyonke.

Isikhathi sokuthunyelwe: Novemba-06-2023